The center’s understated aesthetic belies a building that delivers high performance, achieving net-zero status with a sophisticated combination of sustainable systems and materials. “The project is designed to meet 100 percent of its energy needs through on-site renewable generation and is ‘net-zero-ready,’” according to VMDO. “This is accomplished through passive strategies, such as proper orientation, reduced window/wall ratios, daylighting, shading, and a high-performance envelope); and active strategies, such as geothermal heat pump systems for heating, cooling and domestic hot water, high efficiency lighting, and dedicated outdoor air systems with heat recovery; and renewables.” Structural walls employ a composite of concrete and insulation materials to deliver improved thermal performance.

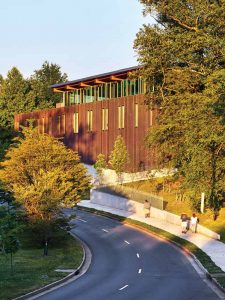

Geothermal heat pumps linked to 20 ground-source water loops reduce the building’s energy usage. Roller shades in the offices and across the south facade control glare and reduce solar heat gain. Along with the vertical standing-seam copper cladding, the rainscreen facade includes thermal break Z furring with more than 114.3-mm (4.5-in.) of insulation, contributing to the community center’s overall energy efficiency.

The copper panels not only boost the resilience and energy efficiency of the building envelope, but they also enhance the overall exterior aesthetics and the beauty of the design.

“Looking at the massing of the building, we wanted the copper to move across the north facade but there were windows there. To keep the views, we perforated some of the panels,” explained Comiskey. “I was surprised how open it is when you look from the interior. You can even see trees across the street.”

Other building elements include about 304.8 mm (12 in.) of polystyrene geofoam above the garage which create grading without excessive weight loads, reducing the concrete needed to maintain structural integrity. An efficient water-management system that collects and filters stormwater for use in irrigation was added as well, and wood paneling and other interior elements made from trees which were cut down during construction. Further, structural walls that employ a composite of concrete and insulation materials to deliver improved thermal performance, and roller shades in the offices and across the south facade to control glare and reduce solar heat gain. All these design elements contribute uniformly to the sustainability of this building.

The Center’s holistic design and advanced performance earned itself wide recognition, including a “best project” citation from the Engineering News Record2 and a North American Copper in Architecture (NACIA) award from the Copper Development Association (CDA).

“The Lubber Run Center not only delivers a high level of sustainability, but also has design features that fit the location and use extraordinarily well,” says Andy Kireta, CDA president and CEO. “The judges particularly recognize how the copper facade panels will oxidize naturally from brown to green over time, helping them integrate even more into the surrounding park.”

Since the building opened, Comiskey says one of the most gratifying aspects of the project has been the positive reactions they have received from Arlington residents.

“It is great how much the community loves the facility,” says Comiskey. “At the beginning, some of them said ‘You’re going to ruin our park,’ but now they are using it, they tell us ‘Wow, we love this,’—this is the best testimony. People are loving how the building just fits with the park.”

Notes

1 To learn more about the project, visit www.vmdo.com/lubber-run-community-center.html.

2 To read the Engineering News Record article, visit www.enr.com/articles/52633-best-sports-entertainment-and-excellence-in-sustainability-award-of-merit-lubber-run-community-center.

Author

Author