Long-term field performance

Several heavy-use installations are success stories for BCSA cement. The San Bernardino Freeway (Interstate I-10) in California provides a good example of the cement’s in-service performance. The Seattle-Tacoma (SeaTac) Airport in Washington is the 15th largest one in the United States in terms of aircraft movement, as well as the Lincoln Tunnel, the world’s busiest underground vehicular passage, represent additional field-installed successes of BCSA cement.

San Bernardino Freeway

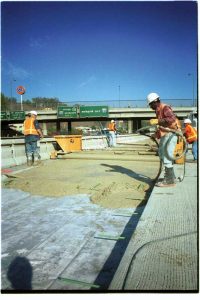

In October 1999, I-10 launched Caltrans’ longer life pavement rehabilitation quality team program. At that time, the project represented one of the most significant rapid-setting concrete placements ever attempted, being a demonstration project utilizing a 55-hour weekend closure (from 10 p.m. Friday to 5 a.m. Monday) with round-the-clock construction operations.

The freeway averaged 240,000 vehicles daily and suffered from severely distressed pavement. During construction, two of the four eastbound lanes were shut down in a section between the 57/210 interchange and Garey Avenue, Pomona. Contractors used 2676 m3 (3500 cy) of rapid-setting BCSA concrete to replace the existing 229-mm (9-in.) thick pavement. The project rehabilitated a 2.8 lane-km (1.7 mi) section of roadway and was completed in the allotted 55 hours. The BCSA cement concrete allowed heavy-duty traffic on the new lanes in three hours following placement. Due to the fast schedule, Caltrans realized future lane closures could be reduced to 30 hours.

Today, after 20 years of service, the repaired section of the San Bernardino Freeway has demonstrated durability. It has not required concrete replacement and displays no apparent problems.

Lincoln Tunnel approach

The Lincoln Tunnel is a 2.4-km (1.5-mi) passage under the Hudson River. It connects New Jersey with Midtown Manhattan in New York City and accommodates approximately 21 million vehicles annually. In addition to eastbound and westbound lanes located in underwater tubes, a third, center tube contains reversible lanes.

By 2004, concrete approaches to the tunnel on the Weehawken side (New Jersey) needed repair. Due to the high-traffic location, the roadway could not be closed for more than a short period of time. The Port Authority of New York and New Jersey (PANYNJ) wanted to accomplish reduced closure times using rapid-setting concrete. Therefore, in July 2004, contractors performed a test pour using BCSA cement concrete. The concrete achieved 4.8 MPa (690 psi) flexural strength in four hours and 6 MPa (890 psi) in 28 days. The success of the test pour led the team to use the same rapid-setting mix for a panel located directly in front of the tunnel, a critical location. In June 2005, the project was complete, with the placement of approximately 160 m3 (210 cy) of rapid-setting concrete.

The BCSA-containing rapid-setting cement used for the Lincoln Tunnel project has, to date, provided 15 years of service, again demonstrating the building material’s durability.

SeaTac Airport

As with other early applications of BCSA, time constraints were the deciding factor in SeaTac project owners’ choice to use rapid-setting concrete. In the early 1990s, one of the airport’s two runways was determined to need repair. As the airport’s only instrument landing system (ILS) runway, it could not be taken out of service. To accomplish quick repairs, a BCSA concrete mix was selected and, starting in 1995 and continuing for more than 10 years, the Seattle-Tacoma airport used the rapid-setting mix to perform night repairs. An estimated 30,000 m3 (39,239 cy) of BCSA cement concrete were poured, both on runways and taxiways.

| REFERENCES |

|