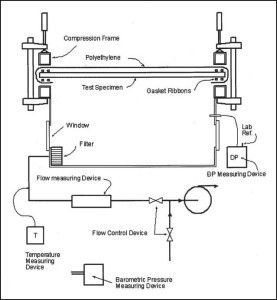

Image courtesy ASTM

The importance of air barriers

Lee Durston is the director of building science at BCRA, a design firm for the integration of building science and innovative technology. In “Achieving Good Airtightness in New and Retrofitted U.S. Army Buildings,” his white paper for the March 2012 U.S. Army Corps of Engineers (USACE) High-performance Building Envelope Workshop he states:

Effective, continuous air barrier systems can reduce air leakage by up to 83 percent, save on gas bills by more than 40 percent, and cut down on electrical consumption by as much as 25 percent.

This research focused on the behavior of multiple barrack facilities with varying construction methods and materials to determine effectiveness of USACE building tightening methods that have taken place ahead of IECC developments.

David Tomasula, a principal with LJB Inc., a design firm that employs tilt-up concrete strategies, concurs.

“With the advent of the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED) in 1998, a large emphasis was placed on the interior guts of the building—the mechanical systems, the electrical systems, the plumbing systems, etc.,” he explains. “Meanwhile, the Department of Energy (DOE) has known the most cost-effective energy efficiency is achieved by building a well-insulated envelope. The building codes are catching up by adopting new criteria such as continuous insulation envelopes and air barriers. This will not only aid in the conservation of natural energy resources, but it will also provide financial savings to building owners, since energy costs account for more than a quarter of the lifecycle cost of owning a building.”

USACE leads the way in the trend toward incorporating air barrier requirements as part of the exterior wall construction. At the aforementioned workshop last year, the focus was on building the ‘perfect wall.’ According to Joseph Lstiburek, a principal with Building Science Corporation and speaker at the conference, this entails four principal layers:

- rain control;

- air control;

- vapor control; and

- thermal control.

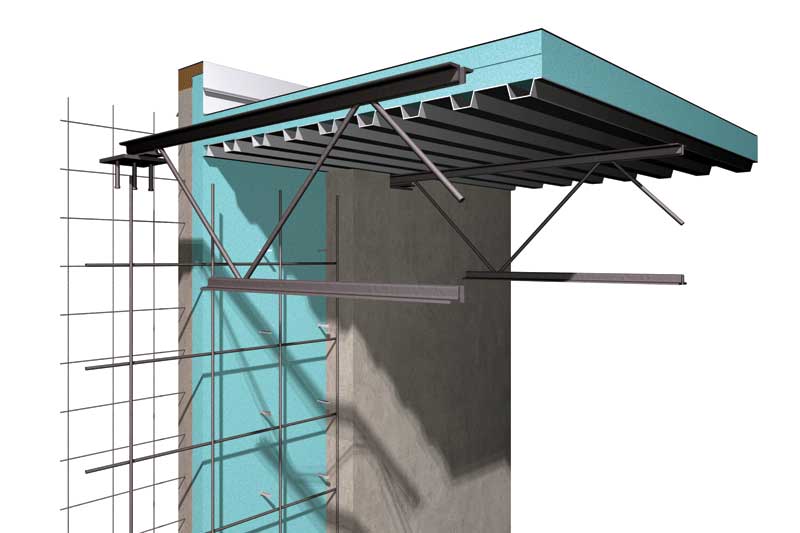

The research from USACE confirms the air control layer can take the form of a supported flexible barrier, such as self-adhered modified bituminous (mod-bit) membrane sheets over concrete masonry or polyethylene sheets over stud walls. Alternatively, the air control layer can be achieved by the concrete tilt-up panel itself—without the need to introduce the cost of an additional material layer.

To evaluate the performance of various air barrier systems and wall construction methods, USACE commissioned whole-building pressurization testing on 200 buildings over a period of 29 months. The testing represented buildings from 34 Department of Defense (DOD) installations and all climate zones in the United States. Building sizes ranged from one to eight stories, and building envelope areas were from 93 to 34,375 m2 (1000 to 370,000 sf). Construction types included wood- or metal-framed walls, pre-engineered metal buildings (PEMBs), tilt-up concrete, and CMUs.

The overall results of the evaluation were positive, showing an average air leakage rate of 0.17 cfm/sf @ 75 Pa was achieved across the entire survey. More impressively, the tightest building tested was constructed of tilt-up construction, achieving an airtightness of 0.04 cfm/sf @ 75 Pa—more than four times tighter than the average leakage rate.

Image courtesy Tilt-up Concrete Association

Looking forward

Another example of the implementation for the 2012 IECC is California’s 2013 Building Energy Efficiency Standard, with effectiveness established for January 2014.

Baty interprets the standard to suggest all new non-residential buildings in the state will require a test prior to occupancy certification in accordance with ASTM E770. This test must return a minimum building tightness of 0.4 cfm/sf. From the data evidenced by the USACE study, the tilt-up industry on average provides tightness 10 times greater than the minimum requirements. This translates directly to an energy efficiency advantage.

With increasing emphasis on high-performance building envelopes in commercial construction—and their role in reducing mechanical heating and cooling costs—tilt-up concrete is well-poised to be recognized for its superior performance.

Kari Moosmann is the editorial manager for Constructive Communications, a public relations and marketing firm for architecture, engineering, and construction (AEC) industries. She has specialized in the construction industry, particularly the concrete segment, for almost 25 years. Moosmann has also launched luncheons, books, and social networking sites for the concrete industry. Additionally, she co-chairs Women in Concrete Alliance (WICA)—an online networking organization for women in the concrete industry. Moosmann can be reached at kmoosmann@constructivecommunication.com.

It sounds to me like it is a similar idea to framing a house with wood. You build the frame ant then lift it and secure it into place. It is just easier to build walls on the ground. So, I am all for using tilt up construction. If it is easier and faster then why not?

Great post!!! Thanks for sharing this information with us…