Making the NAFS short-form specification work

by Dean Lewis

Fenestration products are becoming undeniably more complex as performance expectations diversify and tighten. The same is true of the standards guiding both designers and specifiers of these products.

The focus of these standards is the American Architectural Manufacturers Association/Window and Door Manufacturers Association/Canadian Standards Association (AAMA/WDMA/CSA) 101/I.S. 2/A440, North American Fenestration Standard/Specification for Windows, Doors, and Skylights (NAFS). The 2011 edition of NAFS serves as the basis for product certification as required by the International Building Code (IBC) and International Residential Code (IRC).

Specifying NAFS compliance ensures the specification is based on an objective evaluation because of two essential properties of the standard:

- performance basis: rather than attempting to prescribe detailed physical attributes such as frame thickness, NAFS rates complete, fabricated products according to how well they perform under prescribed conditions; and

- material neutrality: since NAFS is performance-based, it plays no favorites, allowing use of any qualifying framing material.

Basic specification using NAFS

For specifiers, using NAFS to choose a fenestration product involves three basic steps:

- Select the type of window, door, or unit skylight desired. This is also known as the operator type as determined by the way in which the product opens and closes, such as double-hung, casement, or awning. The 2011 NAFS addresses 36 different operator types, ranging from the venerable single-hung to the newer dual-action and parallel-opening windows, as well as sliding and side-hinged doors, plus unit skylights, roof windows, and tubular daylighting devices (TDDs). Each of the 36 types is assigned a unique letter code identifier.

- The environment or application in which the product is to be installed must be considered. In the standard, guidelines are provided to help determine which class of product is suited for a particular application.

- The performance level required for the specific project must be determined.

The starting point: design pressure

The key to understanding product performance requirements, testing, and basic fenestration product specification is the major structurally related aspects pertain directly to the Design Pressure (DP). This is the force, expressed in Pascals (Pa) or pounds-per-square-foot (psf), exerted by the wind velocity likely to be experienced at the building’s location. From this, the Performance Grade and Water Penetration Resistance Test Pressure can be determined. The DP is a starting point for defining the performance of a given fenestration product, but not a performance rating in itself.

The classic reference for determining design wind load is American Society of Civil Engineers/Structural Engineering Institute (ASCE/SEI) 7, Minimum Design Loads for Buildings and Other Structures. This standard includes the well-known map depicting maximum wind velocity contours for the United States (although local codes may cite other requirements) so it is important to consult the authority having jurisdiction (AHJ).

ASCE/SEI 7 cites three additional variables used to establish the actual maximum likely wind load for building envelope components and cladding due to the expected wind speed:

- mean roof height;

- importance factor (i.e. criticality of the structure to life safety); and

- exposure category based on surrounding terrain.

Performance Class

Performance Class roughly describes the likely target application for a window or door. Like DP, it is not in itself a specific performance rating. The four classes defined in NAFS-11 are:

- R Class: one- and two-family dwellings;

- LC Class: low-rise and mid-rise multi-family dwellings, and other buildings where larger sizes and higher loading requirements are expected;

- CW Class: low-rise and mid-rise buildings where larger sizes, higher loading requirements, limits on frame member deflection, and heavy use are expected; and

- AW Class: in high-rise and mid-rise buildings to meet extreme loading requirements and limits

on deflection.

These designations specify incrementally more stringent basic performance requirements to meet increasingly demanding product applications. It should be noted these designations are merely guidelines; the specifier must determine the Performance Class needed for a given job and the specific applicable performance requirements.

To accomplish this, NAFS defines the following four mandatory basic performance requirements within each Performance Class for a completely fabricated product. They are:

- minimum structural load a product must withstand due to wind at the established DP;

- resistance to water penetration due to wind-driven rain, also tied to the DP;

- ability to seal out air leaks that can decrease energy efficiency; and

- security in terms of its ability to resist forced entry.

Performance Grade

The specific performance level of a fenestration product that falls within a given Performance Class is defined by the Performance Grade (PG).

Performance Grade is not the same as the Design Pressure; a product only achieves a specific PG rating if it complies with all NAFS requirements for a certain Design Pressure corresponding to a given maximum expected wind velocity. Key among these requirements are the following elements.

Structural performance

NAFS requires a window or door to withstand a pressure test load applied per ASTM E330, Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights, and Curtain Walls by Uniform Static Air Pressure Difference, first at the Design Pressure, during which the deflection of structural members is measured and recorded. This is known as the Uniform Load Deflection Test. The specimen is further tested at a pressure 150 percent of the DP in the Uniform Load Structural Test. The test pressure is 200 percent of DP for unit skylights and TDDs.

Water penetration resistance

The water penetration resistance test pressure

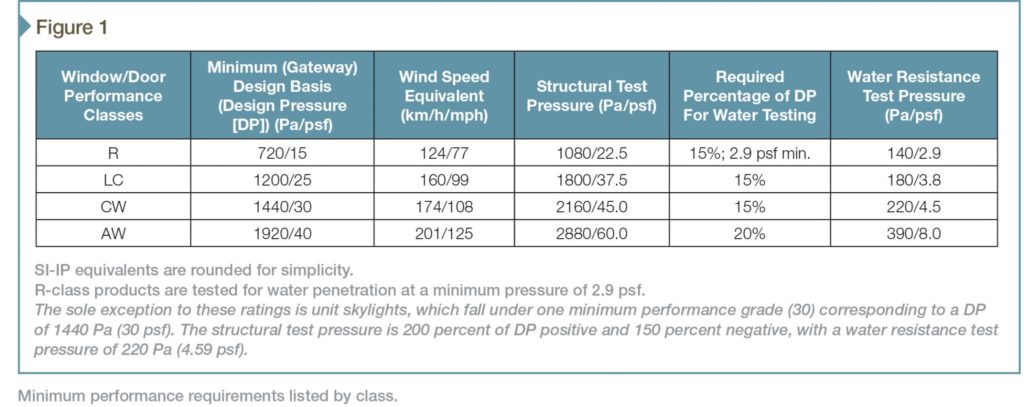

is per test method ASTM E547, Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Cyclic Static Air Pressure Difference. It simulates the force behind wind-driven rain and is generally based on 15 percent of the DP for R, LC, and CW Performance Classes, subject to a minimum of 140 Pa (2.90 psf) and a recommended maximum of 580 Pa (12 psf). The exception is the AW class, which is tested for water penetration per both ASTM E547 and ASTM E331, Standard Test Method for Water Penetration of Exterior Windows, Skylights, Doors, and Curtain Walls by Uniform Static Air Pressure Difference, at a pressure of 20 percent of design pressure, but also is capped at 580 Pa (12 psf) in the United States. The Performance Grade earned by the product will be the Design Pressure as modified by the results of water leakage testing. The lower of the ratings determines the PG.

Air leakage resistance

The air leakage resistance is determined per test method ASTM E283, Standard Test Method for Determining Rate of Air Leakage Through Exterior Windows, Curtain Walls, and Doors Under Specified Pressure Differences Across the Specimen.

While not directly related to DP, the maximum permissible rate of air leakage (expressed in L/s?m2 [cfm/sf]), is a key performance attribute relating to occupant comfort and energy efficiency. Unlike structural and water penetration resistance requirements, NAFS specifies applied test pressures and maximum allowed leakage rates based on different Performance Grades and operator types.

These three criteria—often referred to within the industry as air, water, and structural (AWS)—are the foundation of fenestration performance and the elements for basic third-party certification.

Figure 1

By definition, each Performance Class requires a specific PG be met as the result of testing; the minimum PG increases as one moves up from R to LC to CW and AW Class. This lowest level is known as the entry level or ‘gateway’ performance requirement. Gateway Performance Grades for the four performance classes are shown in the second column of Figure 1.

The level of Performance Grade called for by a specific project may not correspond to the general use categories suggested by the Performance Class. For example, some residential applications may need a CW or even AW Class, while LC might be appropriate for some commercial buildings. It all depends on the specific project’s needs.

A product only earns its way into a given Performance Class when it complies with all the minimum requirements for the designation under consideration. This means not only does the product have to comply with the structural loading performance requirements, but it also must meet:

- air infiltration resistance;

- water penetration resistance;

- resistance to forced entry; and

- various product-specific auxiliary tests that confirm hardware operation under load.

Often, a higher performance level than that of the minimum gateway level is required—in a hurricane zone, for example. If such a higher performance level is to be specified, the standard allows for products to be tested to meet any design load above the gateway minimum in increments of 240 Pa (5 psf). NAFS caps these optional higher grades at 4800 Pa (100 psf) for R, LC, and CW classes; there is no cap for AW products. Again, only after successful entry into the Performance Class at the Minimum Performance Grade tested and at the minimum test specimen size can additional optional Performance Grade testing be conducted.

Additional requirements under NAFS

Specifying NAFS-compliance encompasses a defined suite of performance criteria, as well as referenced standards for materials and components. In addition to those mentioned, there are other product type-specific performance factors falling under the NAFS umbrella that are unrelated to design wind pressure exposure. Among these are:

- forced-entry resistance (if applicable) determined per ASTM F588, Standard Test Methods for Measuring the Forced Entry Resistance of Window Assemblies, Excluding Glazing Impact, or ASTM F842, Standard Test Methods for Measuring the Forced Entry Resistance of Sliding Door Assemblies, Excluding Glazing Impact;

- operating force (if applicable) per ASTM E2068, Standard Test Method for Determination of Operating Force of Sliding Windows and Doors;

- deglazing force determined per ASTM E987, Standard Test Methods for Deglazing Force of Fenestration Products;

- lifecycle testing for AW Class products per AAMA 910, Voluntary Lifecycle Specifications and Test Methods for AW Class Architectural Windows and Doors;

- manufacturing tolerances permitted;

- materials (aluminum and wood specifications plus various polymeric standards governed by standards such as AAMA 303, Voluntary Specification for Rigid Polyvinyl Chloride (PVC) Exterior Profiles; AAMA 304, Voluntary Specification for Acrylonitrile-Butadiene-Styrene (ABS) Exterior Profiles Capped with ASA or ASA/PVC Blends; AAMA 305, Voluntary Specification for Fiber-reinforced Thermoset Profiles; and AAMA 308, Voluntary Specification for Cellular Polyvinyl Chloride (PVC) Exterior Profiles;

- sealed insulating glass durability as per ASTM E2190, Standard Specification for Insulating Glass Unit Performance and Evaluation or CAN/CGSB 12.8, Insulating Glass Units; and

- components (e.g. hardware to meet cited AAMA and/or Builders Hardware Manufacturers Association [BHMA] standards).

Specifying NAFS compliance means the embedded requirements for these factors also must be met and are implicitly included in the specification.

Product Designation

Using the key elements of product type, Performance Class, and Performance Grade, a performance rating can be constructed to specify a window or door for a specific application. The rating, then, is a four-part product designation consisting of:

- Performance Class;

- Performance Grade;

- maximum size tested (which qualifies all smaller products within the manufacturer’s product line of the same design); and

- Product Type (abbreviated).

For example, a horizontal sliding (HS) window may be tested at a size of 1600 x 1118 mm (63 x 44 in.) in Performance Class R with a Performance Grade of 720 Pa (15 psf)—the gateway level for R-class approval. The designation would be:

SI designation: R – PG720 (SI) – 1600 X 1118 – Type HS

IP designation: R – PG15 – 63 X 44 – Type HS

Care must be taken, however, to ensure all requirements of a given Performance Grade are met, or the product must be rated at a lower Grade, which also may result in a lower Performance Class. The manufacturer cannot meet one condition without meeting the other.

For example, an AW-class window tested at 80 psf for structural performance and at 8 psf for water resistance is an AW-PG40 since it only meets the 8 psf water test (20 percent of 40 = 8 psf). Also, this window qualifies as a CW-PG50 since it only meets the 8 psf water test (15 percent of 50 = 7.5 psf).

The same product tested at 50 psf for structural performance and at 12 psf for water resistance is either an AW-PG50 or a CW-PG50 since it exceeds the water test pressure at both the 15 percent and 20 percent level (15 percent of 50 = 7.5 psf and

20 percent of 50 = 10 psf) and since it meets the maximum 12 psf water test ‘cap’ for both classes.

Finally, the same product tested at 75 psf for structural performance and at 12 psf for water resistance is either an AW-PG75 or a CW-PG75 (by virtue of having met the 12 psf cap).

The short-form shortcut

Once the product selection is complete, a product designation is determined, and appropriate compliance testing decided, the selection for the project at hand must be documented. NAFS provides assistance with this by presenting a recommended short-form, fill-in-the-blank specification. Simply add the specific designation (for the Performance Class and the Performance Grade needed, as previously discussed) and the manufacturer that is preferred.

The guide language of the short-form specification is as follows:

All (windows) (doors) (secondary storm products) (tubular daylighting devices) (roof windows) (unit skylights) shall conform to the (product designator) requirements of the voluntary specification(s) in AAMA/WDMA/CSA 101/I.S.2/A440-11, be labeled with the AAMA, CSA or WDMA label, have the sash arrangement(s), leaf arrangement(s) or sliding door panel arrangement(s) and be of the size(s) shown on the drawings, and be as manufactured by (preferred manufacturer) or approved equal.

An example of a completed short form specification for a horizontal sliding LC class window rated at a Performance Grade of 25 (in IP units) would read:

All windows shall conform to the LC-PG25-HS voluntary specification in AAMA/WDMA/CSA 101/I.S. 2/A440-11, be labeled with the AAMA, CSA, or WDMA label, have the sash arrangement and be of the sizes shown on the drawings and be as manufactured by (XYZ Windows) or approved equal.

The specifier is not constrained by the standard’s requirements, as more stringent exceptions still may be included. Additional requirements also may be specified beyond the basics for performance considerations relating to impact resistance, blast mitigation, acoustical characteristics, thermal values, and tornado mitigation.

Conclusion

The specification writer is burdened with the responsibility for a great many building elements; the product designation system, performance requirements and methodology included in the NAFS standard can significantly lighten that burden without sacrificing completeness or quality.

Dean Lewis currently serves as American Architectural Manufacturers Association’s (AAMA’s) educational and technical information manager, bringing his knowledge of technical training to advance the FenestrationMasters professional certification program. Lewis began his career in the fenestration industry at PPG Industries with positions in project engineering, product design, and sales and customer technical support, and he has served on committees of ANSI, ASTM, and ASHRAE. Further experience includes teaching in the industrial and military sectors, and 35 years of managing technical training, publishing, and certification. Lewis holds a bachelor of science in physics with graduate work in engineering management. He can be contacted by e-mail at dlewis@aamanet.org.