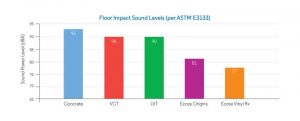

Intertek’s testing shows concrete recorded the highest floor impact sound level of 93 dB, followed by generic VCT and LVT at 90 dB. In contrast, vulcanized composition rubber with cork tested at 81 dB, nine dB lower than VCT and LVT, almost 50 percent quieter. Finally, vinyl fusion-bonded to a vulcanized composition rubber backing had the lowest impact sound level at 77 dB—13 dB below VCT and LVT. A 13-dB decrease in noise level is equivalent to two-and-a-half times of relative quietness in terms of perceived loudness.

Testing also found the floor impact sound levels for vulcanized composition rubber with cork as well as vinyl fusion-bonded to vulcanized composition rubber were below the floor impact sound levels for a bare concrete floor at all frequencies. Floor impact sound levels for these two surface types were also below the VCT and LVT levels at almost all frequencies. At high frequencies, VCT is as much as 24 dB (more than four times) louder than vinyl surfaces with a vulcanized composition rubber backing.

Testing showed vulcanized composition rubber with cork and vinyl with a vulcanized composition rubber backing significantly reduced the ‘click’ (high frequency portion) of footsteps that is prominent with high-heels and hard-soled shoes on hard floor surfaces.

Impact sound transmission

Testing of in-room flooring impact sound is fairly new, but the testing and analysis of impact sound transmission from a room above to a space below has been common for decades. Common industry standards used to determine the severity of impact noise transferred from a source room to a space below are impact insulation class (IIC) and delta impact insulation class (ΔIIC) ratings. These standards play a key role in determining the effectiveness of flooring and flooring underlayments when addressing impact sound transmission from footsteps, rolling carts, and dropped items.

IIC ratings depend on the design and construction of an entire floor/ceiling assembly, but they can be improved significantly with the right selection of flooring and/or acoustical underlayments. Higher IIC ratings mean lower noise levels in the room below.

Where IIC ratings measure the performance of an entire floor/ceiling assembly, ΔIIC ratings just measure the impact insulation performance of floorcoverings and underlayments when tested on a standard 152-mm (6-in.) concrete slab. A ΔIIC rating is essentially the difference in IIC ratings between the bare 152-mm concrete slab, and the 152-mm concrete slab with the flooring and underlayment. For example, if a bare 152-mm concrete slab has a rating of IIC 29 and the addition of flooring and underlayment result in an IIC 52, the ΔIIC rating would be 23. Since ΔIIC ratings are based on a standard 152-mm concrete slab, they provide a better apples-to-apples comparison of the impact insulation provided by flooring and underlayment. However, when comparing underlayments, it is important to note the finish floor tested on top of the underlayment also affects the ΔIIC rating, so it is advisable to only compare underlayment tests using similar finish flooring materials.

Conclusion

Studies reveal loud sound levels can have a negative impact on patient wellness, provider efficiency, and the overall quality of care. To reduce sound levels and improve patient experience and outcomes, many healthcare facilities are now looking to update their site designs and building materials, including flooring selection. When evaluating the healthcare flooring options, it is important to consider the need to reduce noise levels while maintaining high standards of cleanliness to provide safety and comfort to patients and providers. Studies show resilient flooring surfaces backed with recycled rubber underlayment solve acoustical issues without creating a hygiene risk. These single, fusion-bonded materials contribute to a quieter environment more conducive to healing while supporting providers in their delivery of quality care.