Photos courtesy Kingspan

by Patrick Johnson, P.Eng.

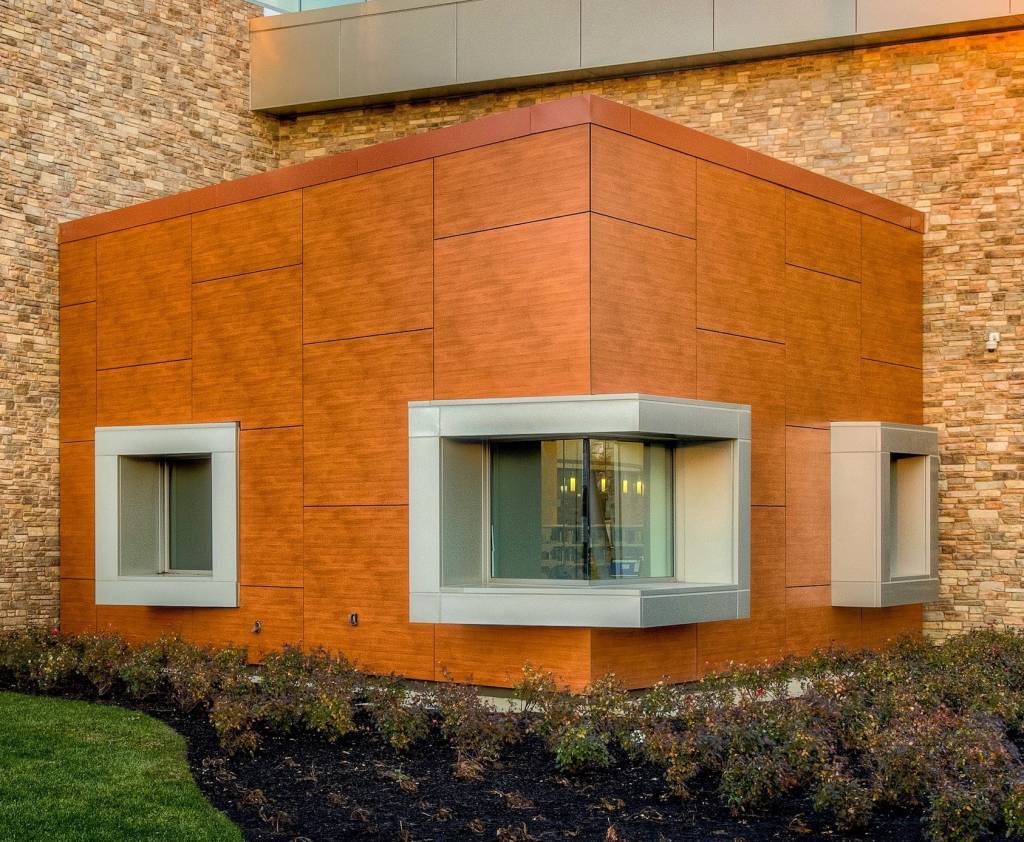

The new Laurel Branch Library in Maryland was built to be much more than a repository for books and other media. Grimm+Parker Architects designed the library to serve as a modern space for discovery, as well as an overall central hub for the local community. The 9753-m2 (32,000-sf) building replaced the original facility, which had been built in 1965.

The new building features a host of modern amenities, including study rooms, a teen zone, a gaming room, and even a dinosaur-themed children’s room, designed as a tribute to dinosaur bones discovered in Laurel.

The exterior of the library features a modern look, designed with its technology-loving patrons in mind. Extensive engineering was required to create some of the signature features of the Laurel Branch Library, which utilizes insulated metal panels (IMPs) in the design. The complex architecture highlights the versatility of IMPs in this case.

The building has a high canopy above the large glass entryway. When drafting the panels for this section of the project, the manufacturer was tasked with aligning the joints around the four sides of the upper sloping canopy, with each side possessing different dimensions. To meet this challenge, 3D modeling was used to establish a joint layout for one section, which was then modeled around the other three sides, allowing all the joints to align once they transitioned around the mitered corners. As a result, almost all the panels used in the canopy are nonstandard width.

The library features eight window-surrounded “pods,” which create interior reading spaces with padded benches and large windows. On the exterior, IMPs frame the windows. Each of the pods, in essence, has a roof, soffit, window sill, and side, inside, and end walls. The specifications for this portion of the project required minimal use of flashings or trim, and stated exposed fasteners were not allowed.

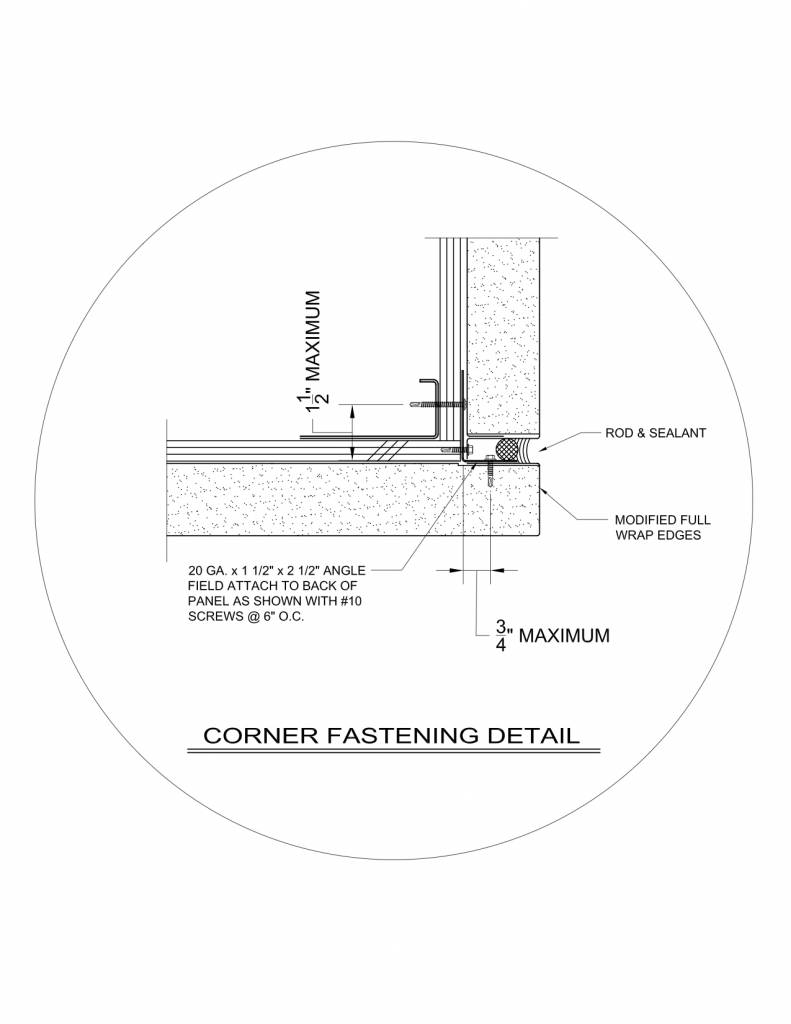

These unique design specifications meant the IMP manufacturer had to develop a new kind of detail that utilized a custom, modified edge panel to make the connection work without any exposed fasteners.

To work around the exposed fastener specification, the panel manufacturer devised a full-wrap edge detail, which involved taking the edge of the metal panel that would normally be configured for a tongue-in-groove interlock and fabricating it into a squared-off condition so it would wrap around the foam insulation and back to the liner-side of the panel (approximately 50.8-mm [2-in.]). From there, an attachment angle was riveted integral to the metal panel so it had a fastening flange that would end up being hidden behind the next panel. Each adjacent panel required its own different kind of modified edge—a partial wrap-edge with a small flange to connect to the previous panel. The trimless corners were stitched together using No. 10 screws. Finally, color-coordinated silicone sealant was used to fill the flashing cavity. The end result was a clean, modern look that met the design intent.

The IMP manufacturer spent approximately three months engineering the panel design for the project. While the design was considerably complex, the installation was relatively simple and was handled by the general contractor. The segments were assembled as if they were each a kit, and could only be assembled one way.

On the back side of the building, a ribbed variation of IMP was also used to form a three-sided screen wall that conceals rooftop HVAC equipment. The same panel extends downward to insulate a lower wall.

The Laurel Branch Library received a 2018 AIA/ALA Library Building Award from the American Institute of Architects (AIA) and the American Library Association (ALA). Judges remarked, “It is inspiring to approach as you walk up into the library and it is awe-producing as you make your way through the inside.”

Patrick Johnson, P.Eng., is chief engineer at BENCHMARK by Kingspan and has a background in civil and structural engineering. He can be reached at patrick.johnson@kingspan.com.

Patrick Johnson, P.Eng., is chief engineer at BENCHMARK by Kingspan and has a background in civil and structural engineering. He can be reached at patrick.johnson@kingspan.com.