by Anthony J. Katona, CDT

The importance of understanding the flashing design principles and installation requirements between the masonry wall assembly and the roof flashing system cannot be overstated. All too often, the exterior masonry walls of a building structure are thought of as being watertight and require little or no maintenance. This perception could not be farther from the truth. In fact, masonry walls are very porous and take on water into the weep cavity. The primary purpose of a properly designed through-wall flashing is to provide an outlet for the accumulated water to evacuate the cavity.

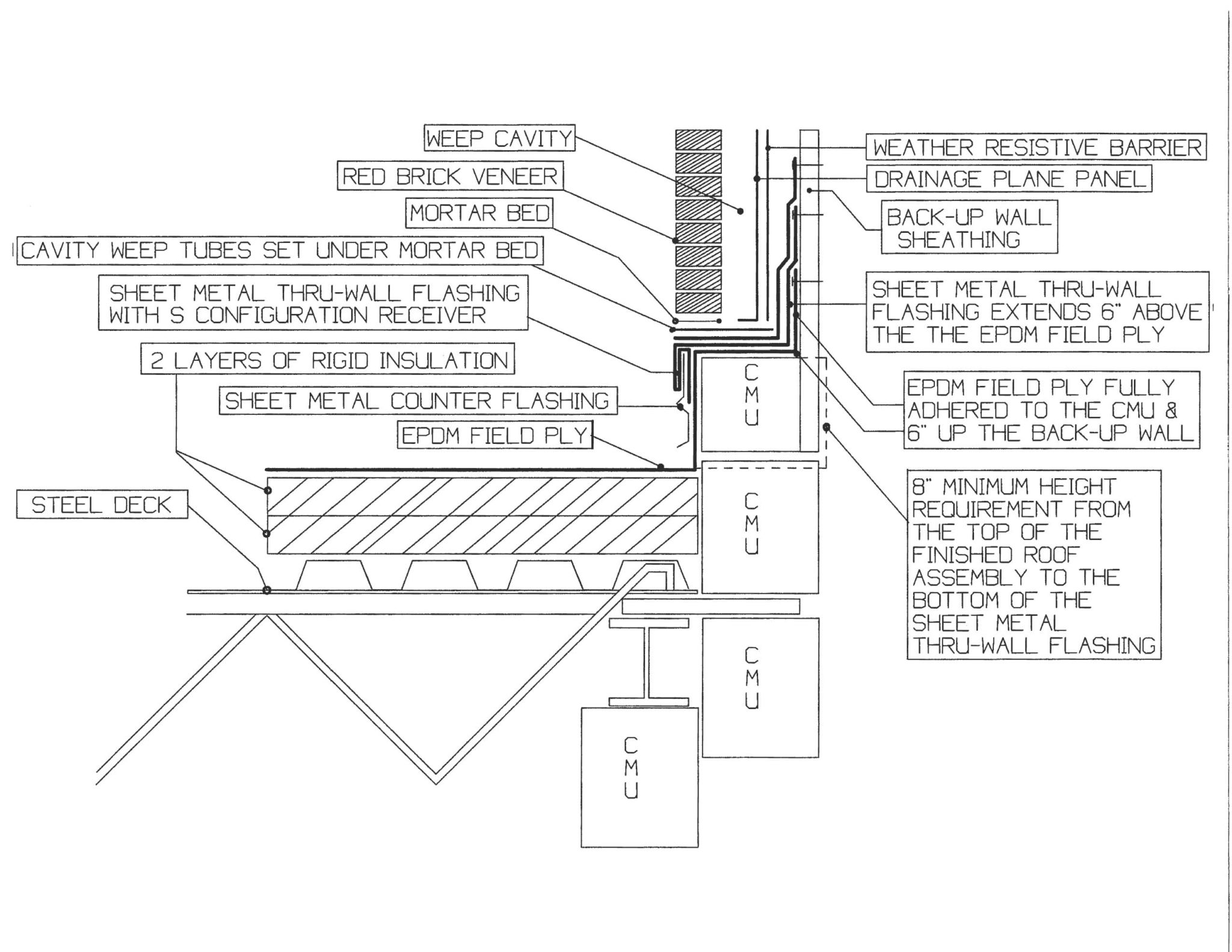

This author’s goal is to effectively communicate how critical it is to have the correct design and installation of the interface flashing assembly. The article uses a hypothetical example—an application on a low-slope commercial ethylene propylene diene monomer (EPDM) assembly from the roof line and above. The proper location of the interface assembly for this article is set at the base of a masonry veneer wall.

Regardless of whether the masonry is a rising wall or a parapet, the design of the detail of the through-wall flashing assembly characteristically remains the same. The author prefers to use a combination of 16-oz. lead-coated copper sheet metal flashing and an EPDM membrane. This technique has proven to function very well, even under the most extreme weather conditions, such as sustained wind-driven rainfall and wet snow.

In this article’s example, there is a point in the construction process where the roof base flashings join together with a masonry wall. While it is common knowledge all roof systems require flashing assemblies to remain watertight, the overall condition of the masonry wall system is rarely given its due attention—it is frequently overlooked altogether when a roof system is being installed, replaced, or reroofed. The exposed portion of the masonry wall system typically includes any portion of a rising wall or a parapet wall constructed above the roof line.

Finding causes of failures

When a roof leak is reported, it is often the case the roof has nothing at all to do with the leak. During these times, the masonry system rising above the height of the roof flashings needs to be evaluated. Frequently, this type of survey is provided by a professional building envelope/commercial roof consultant.

The selected consultant must be highly skilled in the craft of assessing and determining the source of active leaks in order to adequately and properly evaluate the conditions. This inspection will aid in the determination of what actions need to be performed.

Once the mechanism of failure is properly identified, the consultant must also be experienced enough to develop a specification for the scope of work necessary to remediate the problem. The effort may include a non-invasive visual inspection of the roof/wall interface assembly. Depending on the outcome of the initial assessment, it may be necessary to take a closer look.

Another choice is to use Fluid Applied Reinforced Flashing like Kemper System 2K-PUR. It is self terminating, and odor free, and provides long term performance.

Steve-You are correct thart there are several choices to make in order to achieve the objective of providing a means to empty the cavity. However, in my experience there are too may holidays and openings in the wall sheathing material that a fluid applied product could not span. therefore in this example it is not the preferred method. Thank you for your inquiry.

Excellent, I am concerned about the concrete bleeding interface with Aluminum window framing and salt spray ocean environment. Even protected and painted metal roofs lose their finish in less than 15 years. Have you seen any association recommendations?