Images courtesy Alliance Roof Consultants

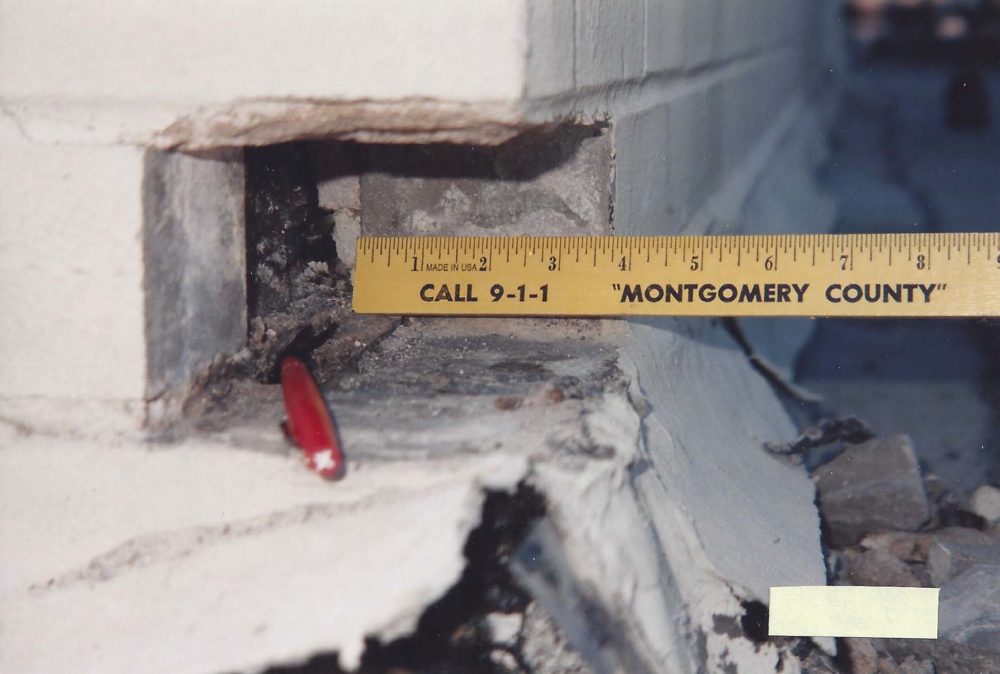

The primary role of these flashings is to take two independent construction systems and join them together to make them watertight. Additionally, these flashings must also provide the means of egress for any moisture accumulating within the weep cavity to drain out. This clearing of the moisture from the weep cavity is essential to keep the building dry.

Figure 1 shows one of many correct ways to properly construct a through-wall flashing assembly. This detail is designed specifically for when new interface flashings are needed at the base of a masonry veneer wall, and wherever masonry will be extended over the interface flashing assembly.

Although the flashings must be accurately designed, it is just as important they be correctly installed. Therefore, there must be open dialogue between the owner, designer, specifier, contractor, and subcontractors involved in the process of achieving a successful outcome.

One excellent method of doing this is to hold mandatory pre-construction meetings that include the project superintendent and the project foreperson (for any portion of the work). By doing so, the personnel actually leading the performance of the work in the field are properly instructed in the procedures called for during the project.

Another highly recommended way is to have a product manufacturer’s representative or a knowledgeable building envelope/commercial roof consultant onsite before the start of the project. The purpose of holding this meeting is for the product representative to perform a demonstration for the construction team (on a mockup assembly). This typically includes the proper installation techniques used to successfully meet the project requirements.

Design principles

The design principles should be specific to the project. This effort may require a closer look at the individual project elements that affect the final design, including the interface flashing assembly. Here are some good general rules:

- Open communication between the design team and the construction team is crucial.

- One must meet the manufacturer’s requirements for minimum base flashing height.

- Backup walls must be sufficient to secure the new through-wall flashings.

- To avoid any discrepancy, the roofing contractor should be assigned the responsibility of installing the specified sheet metal through-wall flashings and the EPDM membrane field and flashing plies.

- The reason flashings terminate a minimum

of 200 mm (8 in.) above the surface of the finished roof system is because this is where the manufacturer’s warranty ends. - Typically, there are certain site conditions on construction projects that require adjustment in the field.

- Any variations should be addressed by the both the design and the construction teams.

Another choice is to use Fluid Applied Reinforced Flashing like Kemper System 2K-PUR. It is self terminating, and odor free, and provides long term performance.

Steve-You are correct thart there are several choices to make in order to achieve the objective of providing a means to empty the cavity. However, in my experience there are too may holidays and openings in the wall sheathing material that a fluid applied product could not span. therefore in this example it is not the preferred method. Thank you for your inquiry.

Excellent, I am concerned about the concrete bleeding interface with Aluminum window framing and salt spray ocean environment. Even protected and painted metal roofs lose their finish in less than 15 years. Have you seen any association recommendations?