Masonry construction: Solving for thermal bridging

A thermal bridge is a location where a more conductive material interrupts a plan of thermal resistivity, reducing the overall thermal resistance of an assembly and possibly leading to enough thermal loss to create condensation. This can lead to mold, mildew, or structural damage. Thermal bridges occur all over a building in transitions, terminations, and penetrations. Foundation to wall transitions, balcony projections, window and door openings, and roof parapets can all be considered thermal bridges.

Often, thermal bridges can be solved with extra diligence, such as tracing the insulation layer around the entire building envelope and circling areas of discontinuity. They can also be rectified with materials like single-barrel screw masonry anchors or a compressed mineral insulation at window heads and floor lines (also addressing fire performance), or gun foam sealant in small gaps and cracks. Aside from the masonry anchors, these are not terribly specific to masonry veneer walls. But, while identifying areas where thermal bridging can occur is a relatively straightforward process, some thermal bridges were harder to solve until recently, as they involved junctions where masonry loads are applied to the foundation below.

Addressing the thermal bridge under masonry veneer

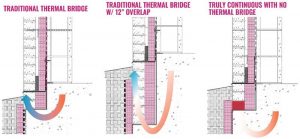

This particular thermal bridge location, where a masonry veneer wall bears onto the masonry ledge at the foundation, creates a linear thermal bridge. This type of thermal bridge occurs continuously across an area as opposed to intermittently, such as with fasteners placed throughout the continuous insulation. There are generally three approaches to this dilemma (Figure 2).

The first would be to not address the thermal bridge at all. While over-insulating elsewhere could be acceptable in some jurisdictions, this solution is a likely barrier to the aforementioned net-zero building or voluntary higher standards like Passive House, which will require extra effort to address these bridges.

The next solution attempts to address the issue by introducing additional insulation, overlapping the area to maintain the temperature at the location where insulation could not be placed. While this solution is demonstrated to address thermal performance, it may come at the cost of additional insulation, additional foundation depth or wall height, and the risk of exposure or damage to the insulation.

However, what if a certain type of insulation had enough compressive strength to help address this thermal bridge? A handful of materials have been introduced to address this thermal bridge without the sometimes-extreme insulation overlap, including composite and homogenous materials. Cellular glass presents an interesting approach to solving for thermal bridging challenges in masonry construction.

Cellular glass structural insulating block

Cellular glass insulation is a mature insulation material (dating back to the 1930s), regarded for its compressive strength, fire resistance, and composition which makes it impervious to water. It is created by combining glass powder and carbon black at high heat to induce a foaming reaction, then cooling the mixture in a controlled environment to maintain the cellular structure. As a result, there is no blowing agent, fire retardant, or other material needed to reach its fire, water, and chemical compatibility properties. This product is used elsewhere throughout the building for roofing and split slab applications, fire stopping, and even in pipe insulation applications, also demonstrating its resistance to extreme temperatures. Installed beneath veneer walls, cellular glass insulation has seen success in addressing unique thermal bridge applications which require high compressive strengths.

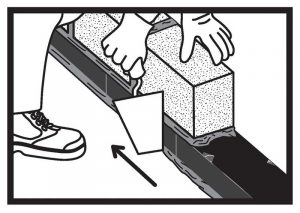

The compressive strength meets or exceeds 1654 kPa (240 psi) (capped) per the American Society for Testing and Materials (ASTM) C165 standard. The material is “capped,” as the manufacturing process requires the outermost layer of cellular structures to be cut to specific dimensions, therefore damaging the outermost cells and creating a layer which would deflect when a load is placed atop the material, until enough of the cellular structure is broken down to create a solid layer of glass material. Capping the material also allows for the attachment of facers which can aid in adhesion—in the case of adhered roofing membranes, or in labeling the material for proper installation. Essentially, a material is “capped” to evenly displace a load and protect from damage prior to and during installation. Using the compressive strength information, a registered design professional may calculate the ultimate load and resulting height of a masonry veneer wall which may be placed atop this insulating block.

Likewise, cellular glass structural insulating block provides a thermal resistance value which is presented in two different directions for a design professional to model and determine the ultimate U-value of a given wall assembly, as previously discussed in the IECC performance method, or for demonstrating compliance with additional voluntary or compulsory standards.