Formwork/reinforcement materials

With any concrete placement method, the selected concrete formwork materials and reinforcing steel supports must be compatible with the waterproofing system. For example, stay-in-place forms, which are composed of a wire-mesh material, can limit the potential for the waterproofing membrane to establish intimate contact with the concrete, creating unbonded sections which may allow lateral water migration at any membrane breach. For this reason, many waterproofing manufacturers explicitly prohibit the use of stay-in-place forms where blindside waterproofing is present.

Another example of a concrete-related construction material having potential incompatibility with blindside waterproofing is the rebar chair. Rebar chairs elevate the reinforcing steel cage from the face of the waterproofing to allow for adequate concrete cover. However, some chair products have sharp edges at their feet, which can damage the waterproofing membrane. It is therefore common for blindside waterproofing manufacturers to prohibit the use of rebar chairs that lack plastic caps on their feet, and to recommend concrete blocks, pavers, or dobies as less risk-prone methods to elevate the rebar cage. Similarly, for mat slabs that include MEP services which will be routed through the slab, the MEP trade contractor may elect to elevate/brace the piping using stands with sharp feet that bear on and risk damaging the membrane. In this instance, concrete blocks or pavers are appropriate, as are base plate details that some waterproofing manufacturers have developed for this purpose.

Duct banks

In general, the most reliably watertight below-grade service penetrations through blindside waterproofing are those in which each penetration has enough clear space around it, such that it can be individually flashed. Duct banks, however, which are composed of a cluster of closely spaced electrical conduits, are influenced by utility providers and electrical contractors not ordinarily integrated with the waterproofing design process. Often sequenced for installation after the placement of the foundation wall, duct banks commonly bring a layer of complexity and unpredictability to the below-grade waterproofing process. Consequently, surprise outcomes in the field where the duct bank configuration bears no resemblance to the waterproofing design or shop drawing details can leave construction teams scrambling for guidance at time-sensitive portions of the project.

With foresight and design coordination, below-grade waterproofing designs can achieve sound waterproofing principles and compatibility with project-specific duct bank configurations. Some example approaches include the following:

- If the duct bank is encased in concrete (i.e. the space between the individual conduits is filled with concrete), treat the duct bank encasement as one large penetration, and apply flashing (extending away from the foundation wall for a few meters [feet]) onto the concrete. Since this work would take place from outside of the foundation wall after it has been placed, the design can incorporate a positive-side-applied flashing detail (using a self-adhered membrane) on the top and sides of the duct bank concrete encasement, and a blindside flashing detail (using an under-slab waterproofing membrane) on the bottom. For a performance benefit, one should also consider installing the top of the concrete encasement with a slight slope to drain off the sides.

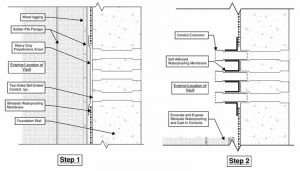

- If the utility provider agrees to allow approximately 101.6 mm (4 in.) of space between each adjacent conduit, and subject to compliance with electrical requirements, set two-sided bell-ended conduits within the foundation wall placement, and when the outside of the foundation wall is excavated to install the duct bank, start the exterior conduit work with a bell-ended conduit stub which can be individually flashed with self-adhered membrane (Figure 5).

Impressive insights on mastering blindside waterproofing! Adopting a proactive and integrated approach is key to achieving long-lasting protection for below-grade structures. This article offers valuable knowledge for professionals in the construction industry.

This blog on mastering blindside waterproofing offers comprehensive insights into proactive strategies for integrated waterproofing solutions. It’s a valuable resource for construction professionals seeking to enhance building durability and performance against the effects of water damage.