Meeting ceiling requirements in restaurant settings

by arslan_ahmed | March 16, 2023 1:21 pm

[1]

[1]By Ben Carr; Michael Chusid, RA, FCSI, CDT; and Steven H. Miller, CDT

Restaurants, cafeterias, banquet halls, commissaries, and other food-service venues typically have at least two different types of ceilings. In the front of house, which includes public-facing areas such as the dining room, bar, and reception area, visual aesthetics are of primary importance, including the ceiling. Acoustic design must consider the desired noise level, as well as speech privacy. Finishes are selected with consideration for illumination strategy and light levels.

In the back of house, comprising the kitchen and other food preparation areas and stations, hygiene and cleanability are key requirements. Acoustic control may be desirable to dampen noise in busy kitchens, while high light reflectance values may also be needed to disperse illumination evenly. Heat from cooking equipment may exclude some products, and ceiling materials used in kitchens must withstand moisture and high humidity. Further, ceilings in both back and front of house must meet building and fire codes, as well as health regulations.

In the back of house, comprising the kitchen and other food preparation areas and stations, hygiene and cleanability are key requirements. Acoustic control may be desirable to dampen noise in busy kitchens, while high light reflectance values may also be needed to disperse illumination evenly. Heat from cooking equipment may exclude some products, and ceiling materials used in kitchens must withstand moisture and high humidity. Further, ceilings in both back and front of house must meet building and fire codes, as well as health regulations.

Some ceiling materials may have the appropriate properties for one area but not the other, resulting in the use of two different types of ceilings in the facility. Currently, the growing trend of open or exposed kitchens has created the need for restaurant ceilings that satisfy both sets of requirements. This article will explore options for meeting these diverse demands.

Front-of-house needs

In public-facing areas of a restaurant, ceilings affect the customer experience in several important ways. The ceiling must complement the visual design of the room, of course, but it also plays a role in the acoustics and illumination of the space. Further, it contributes to customer perception of the establishment’s hygiene and the safety of eating there. The ceiling must also comply with health and public safety codes.

Visual appeal

Interior design has a significant impact on the dining experience and an establishment’s branding. It sets the tone and character of the restaurant, whether it be contemporary, traditional fine dining, rustic cuisine, or fast food. In the front of house, the ceiling’s visual effect can be its primary selection criterion. It is generally the most visible surface in the room, so its impact on design cannot be ignored.1

Acoustics

Acoustics are also of utmost concern in restaurants. Utensils hitting plates and glasses clinking produce particularly penetrating sounds, and an acoustically live room can intensify them. Even more significant is the sound of customers talking, which can carry from one table to the next. Conversations from other tables compete with speakers close at hand, diminishing speech intelligibility. This is often compounded by the Lombard effect, where background noise, including other patrons’ speech, forces people to speak louder, thereby raising the overall noise level even further.

Alternatively, background noise helps protect speech privacy. It masks adjacent sound, preventing speech from being distinguishable at a certain distance. In an open room, speech privacy requires background noise; if occupant-generated noise is not sufficient, electronically produced masking noise may be helpful. Therefore, front-of-house noise levels need to strike a balance between speech intelligibility and speech privacy appropriate to the style of the restaurant.

An acoustic ceiling offers the best opportunity for introducing noise mitigation, especially if it covers a large percentage of a room.2 A study revealed restaurants with acoustic panels in a suspended grid ceiling scored better on both speech privacy and speech intelligibility, and lower on noise annoyance, compared to restaurants with exposed ceilings and no acoustic control.3

Cleanliness

The customer’s perception of cleanliness is also of great importance to a restaurant’s atmosphere. Appearance is psychologically linked to food purity and freshness; thus, a clean-looking restaurant makes guests feel safer. The types of soiling common in the front of house are different than the back of house, and include dust, dirt from the street, spilled food and drink, smoke, and airborne pollution. Ceilings are also subject to soiling in areas near HVAC diffusers. Black or gray discoloration is created by particulates from ventilation streams which attach to ceilings due to the Coanda effect—the tendency of a fluid jet to stay attached to adjacent surfaces. Ceilings should be selected with regard to their ability to be vacuumed, swept, wiped, and washed. Painting can also refresh the appearance of dirty ceilings. However, if not done carefully, it can impact the appearance and noise reduction properties of perforated panels and absorbent materials such as mineral fiber.

Fire safety

The International Building Code (IBC) classifies restaurants under Group A (Assembly) occupancies, but the occupancy classification (and therefore, requirements) of a particular restaurant may depend on its size, the occupancy classification of the overall building in which it is housed, and the code for the region in which it is located. Group A occupancies generally require ceiling finish materials with a flame spread of no more than 150, or no more than 75 if the location is not sprinklered, tested according to ASTM E84.

Again, designers should consult all applicable codes to determine what ceiling materials are acceptable in a particular project.

Lighting levels

Depending on their location, lighting fixtures may or may not involve the ceiling. An intimate setting might only be illuminated by indirect lighting, but a large, cafeteria-style establishment will likely have troffers, downlights, or a luminous ceiling. Light reflectance of all surfaces, including the ceiling, will affect both illumination efficacy and the room’s ambience. A highly reflective ceiling may help meet the adequate lighting requirement.

Front-of-house options

For new construction projects, almost anything—within the safety constraints of building codes—is possible, such as a restaurant ceiling festooned with empty Chianti bottles. However, the following examples constitute some of the more readily available commercial ceiling options for front-of-house areas.

Hard-lid ceilings

Hard-lid ceilings made from gypsum board, plaster, or beadboard are appropriate in many places, and depending on their painted finishes, they are durable and washable. However, they require access hatches to reach overhead services and offer little noise attenuation.

Suspended ceilings

In many restaurants, the overhead structure is left exposed to add visual height to the space and an industrial aesthetic. While this can be economical, savings are reduced by the extra efforts required to make structural members, ducts, and other equipment visually presentable. The added volume can also require additional lighting and air-conditioning capacity.

Most commercial buildings use suspended ceilings to conceal, yet allow access to, above-ceiling cavities which host services such as plumbing, ductwork, electrical, and fire-suppression systems. The most versatile suspension system is the T-bar suspension system conforming to ASTM C635/C635M, Standard Specification for Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings, with either a 610 x 610 mm (24 x 24 in.) or 610 x 1220 mm (24 x 48 in.) module.

While the grid imposes a visual order, the overall character of the ceiling depends on the style of tiles or panels in the grid. Although the flat, white expanse of drop-in mineral fiber panels is common, other options have greater decorative properties, such as three-dimensional panels that create textured, patterned ceilings in a range of styles and colors. If an existing ceiling grid is discolored or damaged, T-bars can be repainted or, to reduce time and labor required, covered with adhesive-backed decorative strips or snap-on grid-cover strips in colors which match or complement ceiling panels.

The standard for mineral fiber and other similar panels, ASTM E1264, Standard Classification for Acoustical Ceiling Products, details certain performance properties. No such similar standard has been written for metal, wood, or thermoformed ceiling panels.

Metal ceilings

Metal ceiling panel systems are made in a great variety of styles, shapes, and finishes. Perforations in panels can improve sound attenuation, and batt insulation or non-woven acoustic fabric backing can improve performance.

[2]

[2]Wood ceilings

Wood ceilings can have a biophilic appeal. To achieve acoustic performance, perforated, slat, or open-cell products can be used. Light reflectance depends on the color of the wood. Wood ceilings may be heavy, and the load must be calculated to ensure it can be supported above.

Thermoformed ceiling panels

Thermoformed panels are relatively lightweight, made from thin sheets of rigid plastic. They are easy to install, and available in a wide palette of colors and three-dimensional decorative patterns. When made from transparent or translucent materials, they can be installed as luminous ceilings beneath economical, color-controlled light-emitting diode (LED) strips. The color of the light can be programmed with a digital multiplex (DMX) controller. This allows the ceiling to change color and lighting intensity throughout the day to create different lighting schemes for the breakfast, lunch, dinner, and late-night crowds, an advancement of the concept known as dayparting in the hospitality industry (Figure 1).

[3]

[3]In restaurants with fire suppression sprinkler systems, some thermoformed panels have an unusual advantage. They comply with NFPA 13, Standard for the Installation of Sprinkler Systems, 3.3.61: “Drop-Out Ceiling. A suspended ceiling system, which is installed below the sprinklers, with listed translucent or opaque panels that are heat sensitive and fall from their setting when exposed to heat.”

Sprinklers can be installed above the ceiling plane and out of sight when the grid is populated with drop-out panels. In case of fire, heat causes thermoformed panels to soften, deform, and drop out of the grid and allows sprinklers to function. Drop-out panels enable the designer to avoid the visual intrusion of sprinkler heads on the ceiling; in luminous ceilings, they also avoid the shadows sprinklers might cast on a luminous panel. Drop-out panels reduce the cost of sprinkler installation by allowing the sprinkler layout to be optimized and by simplifying trade coordination. Similarly, perforated metal panels with at least 70 percent open area can also be installed beneath sprinklers (Figure 2).

Back-of-house needs

In the back-of-house—areas not generally accessible by dining patrons—aesthetics are not usually the driving force in design. The required performance of the ceiling has more to do with supporting the functions of the staff: food preparation and service in an environment that is clean, hygienic, and safe to work in.

Cleanliness

Behind the scenes of a restaurant, hygiene is top priority in food preparation areas. Health Codes require a ceiling that is cleanable and non-absorbent in food preparation areas. Cooking has been identified as a significant source of indoor air pollution, and grease, smoke particulate, and stains from foods such as red wine, mustard, and cooking oil are tough to remove. Finishes must withstand water, cleansers, and degreasing agents, as well as the scrutiny of public health officials.

Commercial kitchens generally have overhead fire suppression systems, exhaust fans, pipes, and ductwork upon which grime can accumulate and then fall into food. Such a situation would fall afoul of the general requirement for sanitary conditions. A drop-in suspended ceiling (if it does not interfere with a sprinkler system) can block such contaminants from coming into contact with, or falling from, the overhead services, while still leaving services accessible for maintenance.

[4]

[4]Moisture management

Food preparation areas can be humid and wet environments. They are prone to condensation and leaks through the numerous roof penetrations for plumbing and venting. Finishes should be non-absorbent and resistant to sagging and the growth of mold and bacteria.

Conventional mineral fiber panels are absorbent, and once wetted, can sag (Figure 3). The exposed surface of vinyl-faced mineral fiber and gypsum board panels are washable, but they can still absorb moisture from above and through their edges.

[5]

[5]Acoustics

Kitchens are often noisy working environments, and acoustic control may be needed to allow clear communication among the staff and to limit noise escaping to quieter customer areas. It is not practical to perforate kitchen ceiling panels, as doing so allows contaminants to accumulate above the ceiling. Thermoformed panels avoid this problem because they act as diaphragms which allow noise to pass through the ceiling and dissipate in the cavity above. However, it should be noted thermoformed panels should not be used above ovens, ranges, and exhaust hoods, or where ceiling temperatures exceed limits stated by the manufacturer (e.g. one popular brand of thermoformed panels has a ceiling temperature limit of 49 C [120 F]).

Light reflectance

Ceilings with high light reflectance provide more economical illumination, enhance safety, and improve productivity. Ceilings with high light reflectance help distribute illumination more evenly and less unidirectionally, reducing shadowing and providing a safer working environment.

Back-of-house options

Some key terms used in code, such as “cleanable,” are not defined. Several manufacturers now offer unfaced, premium-grade mineral fiber panels for use in commercial kitchens; and they are offered as cleanable materials, capable of being disinfected. One manufacturer recommends cleaning either by vacuuming or light wiping with a mild detergent, and disinfecting by fogging with a special disinfectant/cleaner, spraying with highly diluted bleach, or wiping with diluted hydrogen peroxide. The manufacturer’s data sheets and warranties indicate the ceiling panels are not to be cleaned any more aggressively than lightly wiping them with a damp cloth.

Other ceiling candidates include stainless steel, anodized or painted aluminum, thermoformed plastic panels, and glass fiber composite panels. These products perform well in humid and dirty environments. They can be washed in place or, if necessary, removed from the ceiling grid to be soaked or hosed (Figure 4).

| BAVARIA DOWNS BANQUET HALL |

[6] [6]The ballroom at Bavaria Downs was designed for weddings, and its luminous ceiling is part of the festivities. Using color-controlled light-emitting diodes (LEDs) and translucent thermoformed ceiling panels, the popular Chaska, Minnesota event and wedding venue changes its look to suit the occasion. The broad, pitched ceiling can mimic a vast skylight on a beautiful blue afternoon or match the bridesmaid’s gowns. It can even be synced to the sound system. |

[7]

[7]Strength and cleanability

Standardized tests can be used to evaluate the relative merits of various ceiling products to withstand the high demands placed on restaurant kitchens regarding hygiene, as well as the ability to withstand cleaning and the wear caused by handling tiles during cleaning procedures.

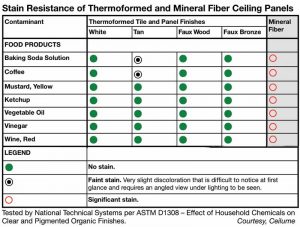

Reports on products that have been tested according to ASTM D1308, Standard Test Method for Effect of Household Chemicals on Clear and Pigmented Coating Systems, may provide some guidance on stain resistance and cleanability relative to food substances. Reagents are applied to specimen, allowed to sit, cleaned using prescribed techniques, and then visually examined (Figure 8).

Some ceiling manufacturers, unfortunately, make vague representations about the performance of their products without explaining the basis for their claims. While ASTM cautions that lab testing does not necessarily replicate field conditions, test results can be used for comparison and should be requested when considering products for which the specifier does not have firsthand experience.

[8]

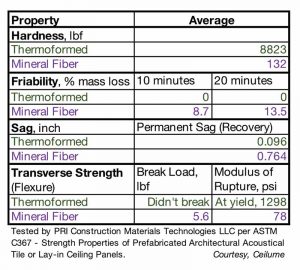

[8]ASTM C367/C367M, Standard Test Methods for Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-in Ceiling Panels, is the ceiling industry’s recognized consensus standard for measuring four characteristics of ceiling products:

- Hardness is determined by the depth of an indentation made by a dropped weight. Greater hardness correlates to a panel’s increased resistance to impact and abuse.

- Friability measures the weight of material which erodes when specimens are placed in a rotating tumbler. Less weight loss indicates a reduced likelihood of edge damage when a panel is installed or handled during maintenance. Some friable ceiling materials are stable when intact, but when damaged may shed respirable fibers, which may include silica fiber, a hazardous material. Materials tested with greater hardness and/or lower friability reduce the likelihood of fiber shed.

- Sag resistance is determined by exposing a product to high humidity, allowing it to return to normal ambient conditions, and measuring how much permanent sag occurs. Panels with less sag indicate greater resistance

to moisture. - Transverse strength indicates a panel’s resistance to breakage from impact or being dropped.

See Figure 7 which provides an example of test results pertaining to ASTM C367/C367M.

| TACO BELL CANTINAS AND INLINE URBAN RESTAURANTS |

[9] [9]Taco Bell, the Mexican-food restaurant chain, has upgraded numerous locations to make more architecturally appealing interiors. The new styles, introduced prior to the pandemic, are designed to bring Taco Bell customers out of the drive-thru and inside the restaurant. With greater seating space and more style and visual interest than many old Taco Bells, they feature localized designs and artwork, open kitchens, digital menu boards, and unique menu items not found at a regular Taco Bell. |

[10]

[10]Open kitchens

The concept of an open or exposed kitchen is not new. Anyone who has watched a short-order chef flip burgers on the other side of a lunch counter or admired the flourishes of a sushi itamae at the cutting board has experienced their performance in an open kitchen. Their polished motions, the sizzle of the grill, and the wafting aroma is part of the dining experience. An expanded variety of dining establishments have placed some or all of their culinary areas in view of their patrons. The concept has been growing, especially in fine dining establishments, as guests have grown more cautious about food quality and purity. Restaurateurs see transparency as a way to allay these fears. An open kitchen can also be a form of entertainment.

[11]

[11]One approach is to differentiate the seating and culinary zones by using different types of ceilings, such as a lay-in ceiling over seating juxtaposed against a hard-lid soffit above food prep. The alternative is to use a single ceiling product throughout the room—one that is attractive and acoustical, yet also impervious and cleanable. The latter approach has the advantages of visually unifying the space, reducing construction costs, and facilitating relocation of the culinary area without needing to remodel the ceiling. Examples range from the elegant antipasto bar (Figure 5) to the no-nonsense service line (Figure 6).

Ceilings à la carte

In addition to front- and back-of-house ceiling “entrees,” some facilities also require a selection of ceiling “hors d’œuvres” for ancillary spaces. For example, entryway vestibules may require hold-down clips to prevent suspended ceiling panels from uplift due to changes in air pressure when doors open. Toilet room ceilings, ranging from mundane to elaborately themed designs, should be selected with regard to potential exposure to water and humidity, as well as the rigors of frequent and aggressive cleaning. Back-of-house areas such as dry storage and staff break rooms can be ceiled with less robust products than culinary areas. The front-of-house may also have a range of requirements for ceilings in lobbies, lounges, meeting rooms, and other settings.

With so many types of ceilings on the menu, the challenge is to find the perfect recipe for a project’s success.

Authors’ note: Michael Chusid, RA, FCSI, CDT, who passed away in 2022, was a recognized authority on building products, and a frequent contributor to The Construction Specifier. He played a significant part in the writing of this article, although he was, unfortunately, not able to review the final version.

Notes

1 A study of retail establishments compared the relative visibility of ceilings and floors as seen by a customer entering the front door. It found, on average, five times more ceiling is visible because floor space is concealed by furniture and fixtures. For more information, visit http://bit.ly/ceiling-floor-ratio[12].

2 “Acoustic ceiling” and similar terms refer to all types of ceilings which have noise-reducing properties. It is not a synonym for “mineral fiber ceiling.” If the term is used in construction documents, the product requirements must be clearly identified in project specifications.

3 See “Good Acoustical Quality in Restaurants: A Compromise Between Speech Intelligibility and Privacy,” by Arianna Astolfi and Marco Filippi, Marco, published in 2003 by Politecnico di Torino. For more information, visit https://www.researchgate.net/publication/267920089[13].

Authors

Ben Carr is the customer service manager for ceiling manufacturer Ceilume. Carr can be reached via www.ceilume.com/pro.

Ben Carr is the customer service manager for ceiling manufacturer Ceilume. Carr can be reached via www.ceilume.com/pro.

Steven H. Miller is a construction document technologist (CDT) and freelance writer specializing in issues in the construction industry. Miller can be reached at steve@metaphorce.com.

Steven H. Miller is a construction document technologist (CDT) and freelance writer specializing in issues in the construction industry. Miller can be reached at steve@metaphorce.com.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG24_Ceilume-LittleJumbo-Overall-3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG27_Ceilume-BavariaDowns-Deep-Violet-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG28_Ceilume-SmallBatchOrganics-SprinkerAboveCeiling-BackgroundSoftened-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG28_Olivers-Market-EdDavis-Edit.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG30_Ceilume-SmallBatchOrganics-WashingPanel.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG27_SideBarBavariaDowns.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG30_ASTM-C367-SummaryTable-Wide.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG30_StainTestMatrix-ShortForm-Sanitized.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG31_SideBarTacoBell-SeaRanchCA.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG28_Ceilume-ItalianKitchen-FoodCounter-02-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2023/03/PG28_PizzaPizza-IMG_2714-editv2.jpg

- http://bit.ly/ceiling-floor-ratio: https://www.ceilume.com/pro/ceiling-to-floor-visibility.cfm

- https://www.researchgate.net/publication/267920089: https://www.researchgate.net/publication/267920089

Source URL: https://www.constructionspecifier.com/meeting-ceiling-requirements-in-restaurant-settings/