by Stanley Yee, LEED AP

Creating an effectively insulated envelope is necessary for buildings to meet the latest demands of ever-tightening energy codes. Innovative use of high-performance insulation technologies enables architects to achieve improved insulation performance using common building techniques without sacrificing aesthetics.

Thin-profile, high-performance insulation materials that seamlessly integrate into conventional glazing systems now give designers flexibility to better manage and balance thermal performance and façade aesthetics. Materials such as vacuum insulation panels (VIPs), architectural insulation modules (AIMs), and aerogel building insulation blanket materials are becoming more prevalent.

For many years, inexpensive energy made it possible to design buildings without regard for energy performance. The global movement toward sustainability has led to tightening regulations often restricting design freedom.

![Integrated use of high-performance insulation in the curtain wall spandrel, in Calgary, Alberta, enables high window-to-wall-ratio designs that meet energy codes. [CREDIT] Photo courtesy BIG](http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_May_2014_HR-25.jpg)

- 2012 International Energy Conservation Code (IECC);

- Living Building Challenge;

- growing demand for net-zero buildings; and

- American Institute of Architects’ (AIA’s) 2030 Challenge.

From a design standpoint, simply increasing the amount of conventional insulation used in a building is neither practical nor aesthetically pleasing. New insulation technologies provide the performance advantages necessary to achieve effective building envelope insulation without sacrificing design aesthetics.

Balancing design trends with energy performance

Cognizant of the need for energy performance, architects are put in a challenging position. Designers are pressured by current building trends to include as much glazing and vision area as possible for optimal aesthetic value, striving to create iconic buildings of aluminum and steel with floor-to-ceiling glass. However, this rise in the use of glass means increasing energy performance can be challenging.

![Thermal performance of commercial insulation materials. [CREDIT] Images courtesy Dow Corning Corporation](http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_May_2014_HR-26.jpg)

Used on the façades of commercial buildings, these opaque spandrel sections—typically composed of metal, stone, or glass panels—are used to conceal the floor lines. The spandrels are often designed to visually blend so closely with the vision glass they are not even perceptible, creating the effect of a uniform, all-glass building (Figure 1). They also are manufactured in various colors and designs, adding additional visual interest to the curtain wall’s appearance.

More importantly, the spandrels can be highly insulated to contribute to the façade’s overall thermal performance. Leveraging technical design opportunities in the spandrel sections allows designers to maximize the vision area and still meet prescribed thermal performance requirements of energy conservation codes, such as ASHRAE 90.1 and IECC.

Traditionally, spandrel areas need to be supplemented with an additional layer of thick mineral wool or similar conventional insulation to achieve the necessary thermal value. However, in higher climate zones, such as Climate Zones 4 and 5, this approach may require additional space within the curtain wall to accommodate the required thickness to achieve thermal performance targets. Thin-profile high-performance insulation technologies can solve these challenges.

Beyond the building’s outward aesthetics, architects are also facing the challenge of mitigating uncontrolled thermal losses due to thermal bridging across the building envelope. These heat losses typically occur at transitional conditions in building envelopes, such as:

- exposed slab edges;

- where glazing systems meet cavity wall components;

- where below-grade and above-grade systems meet; and

- where parapets meet roofs.

Building codes and regulations now require mitigation of thermal bridging conditions. They can make it especially challenging for architects to retrofit existing designs with insulation solutions meeting both performance requirements and available space limitations.

New applications for high-performance insulation technologies

Architects and designers have additional flexibility to respond to insulation performance challenges with high-performance insulation technologies, such as vacuum insulation panels. VIPs can be integrated into architectural insulation modules to enable whole-wall envelope thermal performance improvements; aerogel building insulation blankets can also be included to help address detail-specific thermal bridging issues. These materials not only demonstrate a step-change in thermal performance compared to traditional insulation materials, but also enable designs using current construction techniques to meet demands of the next generation of thermal requirements.

Figure 2 shows the thermal resistance (i.e. RSI, R-value) which is typically expressed as R-value per inch, of various insulation products, including materials typically found on a job site such as expanded polystyrene (EPS), mineral wool, and polyisocyanurate (polyiso). As demonstrated by Figure 2, the change to higher-performing materials is significant, with silica-fume-based vacuum insulation panels as high as RSI 5.63 to RSI 6.16 per 25 mm (R-32 to R-35 per inch) and the aerogel building insulation blanket at RSI 1.73 per 25 mm (R-9.8 per inch).

Thin-profile vacuum insulation panels

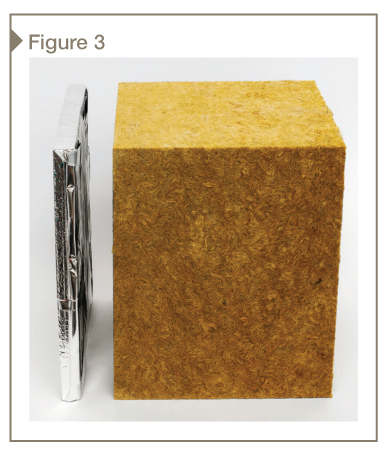

Vacuum insulation panel technology provides designers with new options. Offering insulation in a slender profile, a VIP’s thermal performance gives it the equivalency of eight to 10 times the thickness of mineral wool insulation typically used on a construction site (Figure 3).1

Forms of vacuum insulation were invented more than a century ago, and interest has grown over the past several decades in applications where constrained space and weight benefits justify the higher cost, such as commercial applications, as well as in ‘cold-chain’ applications, such as insulated shipping and transport containers. Now, the technology is finding its place in commercial façade insulation applications.

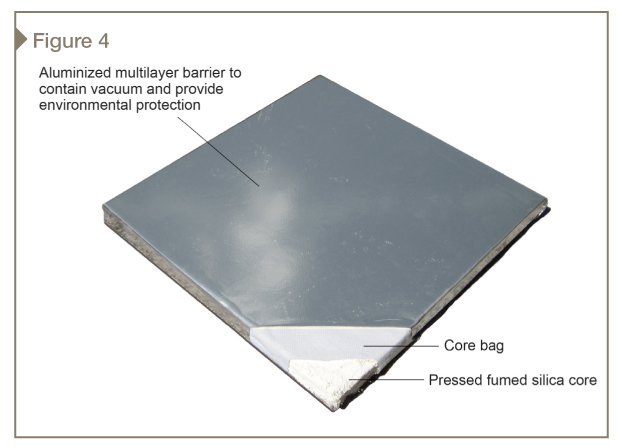

VIP construction (Figure 4) is based on a pressed fumed silica core, which is formed and heated to drive out the moisture. It is then inserted into a handling bag (i.e. core bag) and then into a multilayer, aluminized bag. As that bag is put under full vacuum, its edges are heat-sealed. When the vacuum is released, a full vacuum is contained within the bag. With the vacuum, all the atmospheric gases around the fumed silica are removed, therefore eliminating convective heat transfer from the gases within. With the full vacuum, the unit achieves the initial RSI 5.6 to RSI 6.2 per 25 mm (R-32 to R-35 per inch) center-of-panel (COP) performance. Without the vacuum, the material provides about RSI 1.4 per 25 mm (R-8 per inch), which is approximately twice as good as typical foam insulation—so even if the material loses its vacuum, it continues to provide good insulation performance.2

VIP offers many advantages. It has low nominal thermal conductivity—approximately 4 mW/mK at COP. The metalized bag around the panel is inherently moisture-resistant. The fumed silica core is an ash created by burning a silane. Essentially, the material has already been burned, providing a high degree of fire resistance. The VIP’s thin profile can also allow it to solve various problems; for example, increasing thermal performance requirements not being met by conventional means, or maintaining thermal performance requirements while allowing for increased vision area.

VIP is a pre-engineered product and must be customized by the manufacturer or packaged as part of a system; it cannot be cut to size onsite, as cutting or puncturing the material would cause a vacuum loss and resulting loss of thermal performance.

AIMs–integrated curtain wall application of VIP

The façades of modern glass curtain walls typify an ideal application for vacuum insulation panel technology. Curtain walls create the iconic artwork and unique character of a building. The ability to maintain a slim façade with a high thermal performance gives the architect the design freedom to maximize the wall’s vision area and/or thermal performance while still meeting local building codes.

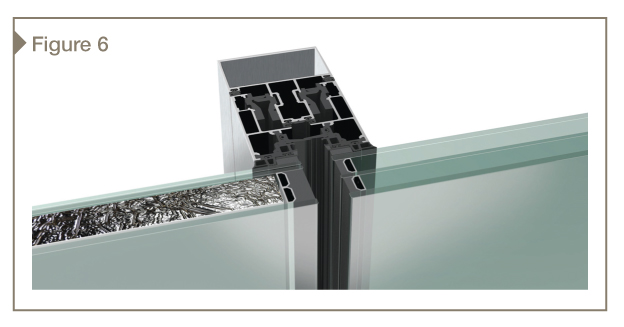

For curtain wall applications, VIP technology is provided in an integrated façade module known as an architectural insulation module, which combines a VIP with a protective architectural finish (Figure 5). The module has a back pane of a rigid structural panel material, joined with a warm edge spacer (as used in the insulating glass industry) around the perimeter. VIP is inserted into the space—which typically is the air space in an insulating glass unit—and covered with a finished panel on the front. Modules are available in various architectural options, including opaque, metal, and glass with ceramic frit or ceramic frit patterns (Figure 6).

Modeling and guarded hot-box testing demonstrates the performance characteristics of architectural insulation modules technology (Figure 7). A 25-mm (1-in.) thick unit modeled with a two-dimensional finite element thermal analysis software package, resulting in an effective RSI 1.90 (R-10.84) and a COP value of RSI 3.84 (R-21.8).

A 50-mm (2-in.) thick unit is tested with ASTM C1363, Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot Box Apparatus. Figure 7 shows actual test results of a 50-mm thick structural panel, which includes a 6-mm (1/4-in.) piece of glass on each side and a 38-mm (1.5 in.) VIP in the interspace, sized at 1.5 x 1.5 m (5 x 5 ft), indicating an effective RSI of 3.4 (R-19.05). The effective R-value is lower due to factors including heat losses around the insulating glass spacer assembly.

In addition to demonstrating superior thermal performance, the AIM is designed to meet the physical demands of commercial façade applications, withstanding typical windloads and meeting structural requirements. Constructed to standard or custom spandrel size specifications, the modules require no special installation techniques, eliminating need for specialized installer training.

Whole-wall insulation performance

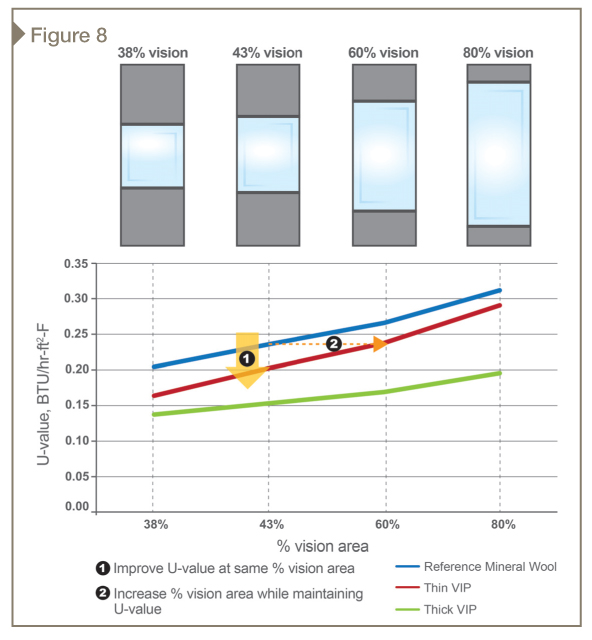

Designing a slim façade with a higher percentage of vision requires the lowest possible U-values for spandrel areas to augment thermal performance characteristics. VIP-integrated façade modules enable additional vision area while still complying with thermal performance requirements, improving the curtain wall’s overall whole-wall performance.

When this technology is applied to a building design, it increases thermal performance by maintaining the same window-to-wall ratio, but its replacing of traditional insulation with architectural insulation modules, increases overall curtain wall thermal performance (Figure 8, Arrow 1).

Further, it increases design freedom as architects gain ability to potentially increase window-to-wall target ratios substantially, without compromising on the insulation value of the curtain wall configuration (Figure 8, Arrow 2X).

Blanket insulation

Like the vacuum insulation technology, aerogel is not a new concept, but it has been optimized for the next generation of building challenges. Invented in the 1930s, the material is composed of 95 to 99 percent air, making it one of the lightest materials. Its nanoporous structure minimizes thermal transport, giving it low thermal conductivity. It has been used in various applications, especially aerospace, but with tightening environmental requirements and increasingly complex building designs, aerogel insulation has now found a new niche providing thermal protection in space-restricted areas.

An aerogel building insulation blanket is made from synthetically produced amorphous silica gel. It features a small particle size, with the diameter of the spaces between aerogel particles similar to the fumed silica in the vacuum insulation panels. Manufacturing this material in a blanket form (Figure 9) creates a usable, flexible, construction-friendly material that can be cut-to-size onsite and applied to reduce the thermal bridging at specific locations in a building envelope assembly. Aerogel building insulation blankets are highly resistant to flame, with an ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials, Class A fire rating (flame spread index 5, smoke developed index 10).

Minimizing thermal bridging

Updating architectural details to address thermal bridging concerns has become more common due to increasingly explicit and stringent building codes. The availability of a thin, flexible insulation material reduces the need to make trade-offs in design to meet codes and regulations, and it eliminates bulky or messy insulation from those tight areas of building designs.

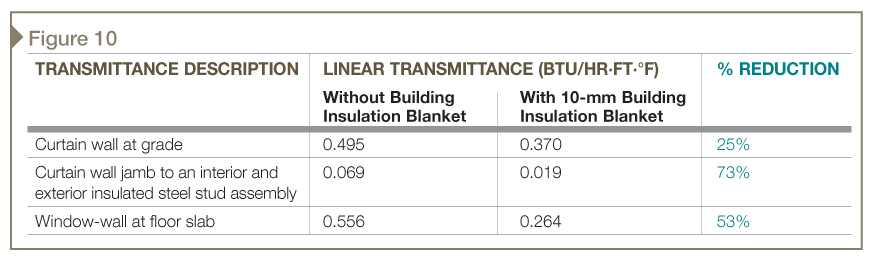

Based on ASHRAE Research Project (RP) 1365, Thermal Performance of Building Envelope Details for Mid- and High-rise Buildings, three common construction details were modeled to demonstrate the effect of using aerogel building insulation blankets to minimize thermal bridging. These models are:

- curtain wall-at-grade detail with the aerogel building insulation blanket applied from the neck of the curtain wall to the below-grade rigid insulation, resulting in a reduction in linear thermal transmittance approaching 25 percent;

- curtain wall jamb at the exterior and interior insulated steel stud assembly with the aerogel building insulation blanket applied around the adjacent steel stud and at the wall-to-curtain wall transition, resulting in a reduction in linear thermal transmittance approaching 70 percent; and

- rehabilitated window-wall system with the aerogel building insulation blanket at the slab edge and around vertical and horizontal glazing mullions, resulting in a reduction in linear thermal transmittance approaching 53 percent.

Lineal transmittance values can readily be incorporated into thermal models. This eliminates the guesswork and improves the predictability of the heat loss due to thermal bridging at those locations. (See Figure 10.)

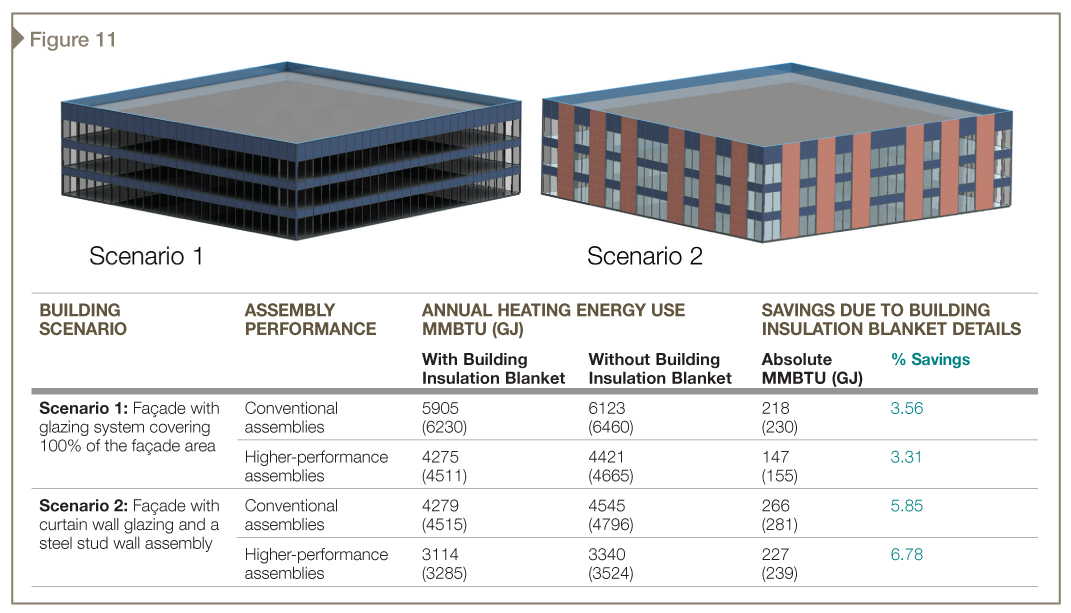

Additionally, two whole-building energy models were created to demonstrate the effect of using aerogel building insulation blanket with conventional and higher-performance assemblies to minimize thermal bridging:

- for a building with the glazing system covering 100 percent of the façade area, addition of the an aerogel blanket, with conventional assemblies resulted in a 3.56 percent energy savings;3 and

- for a façade with curtain wall glazing and a steel stud wall assembly, addition of the aerogel blanket and higher-performing assemblies resulted in a 6.78 percent energy savings.4 (See Figure 11)

Conclusion

Vacuum insulation panels, architectural insulation modules, and aerogel building insulation blankets have been introduced in a range of construction projects in the United States and Europe, with positive response.

In an age of increasingly dramatic building design, architects can take comfort in knowing design does not have to take a backseat to performance and energy efficiency issues in current designs can often be addressed with innovative application of high-performance insulation materials.

Notes

1 For more information, see ASHRAE Fundamentals Handbook 2009. (back to top)

2 Visit Vacuum Insulation: Panel Properties and Building Applications at www.ecbcs.org/docs/Annex_39_Report_Summary_Subtask-A-B.pdf. (back to top)

Stanley Yee, LEED AP, is a façade design and construction specialist for Dow Corning High Performance Building Solutions. He joined the company in 2012 with nearly 20 years of experience in the building enclosure industry, working with curtain wall contracting, façade consulting, and enclosure detailing specialists both nationally and internationally. Yee earned a bachelor of engineering degree from Concordia University (Montréal, Québec). An active member of several industry organizations, he is an elected officer of the Board of Directors for the Glass Association of North America (GANA), representing the Energy Division. He can be contacted via e-mail at stanley.yee@dowcorning.com.

To read the sidebar, click here.

This was a very interesting read, thanks for sharing!