Design considerations

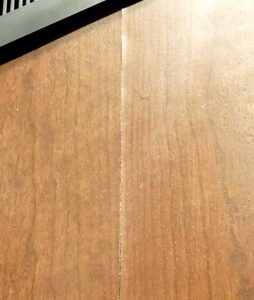

Photo © Mitchel Taylor

Since the amount of overall dimensional change in materials is a function of the size, some types of millwork are more of a problem than others. Casework is less of a problem as casework is typically built-in units allowing for movement. The standard gaps between doors and drawer fronts provide space for expansion, and there is a gap with scribe filler at the end of a run. However, the doors at tall storage cabinets are more susceptible to warping due to their size. When a fixed shelf is used at mid-height, the doors can be divided into upper doors and lower doors, minimizing warping.

Larger structures provide more challenges. Nurses stations can be quite long, and unless some joint or gap allows for movement, there are potential problems. This is particularly important when differing materials are used. Solid surface material is like metal in that it moves with temperature but not with humidity. If a wood substructure does not have expansion joints built in, the differential movement between the solid surface and the substructure can cause failures in the top.

Paneling requires the most allowance for movement. A large expanse of paneling may be envisioned as a monolithic surface, but that can turn into a disaster. Without expansion joints, cracks or buckling can occur. Theaters and performance spaces are common places for large panels; they are also locations where HVAC systems are turned off or down to minimal settings when they are not occupied. Local climate conditions should be considered during their design. The NAAWS has examples of reveal, quirk, and offset joint details that can be referenced.

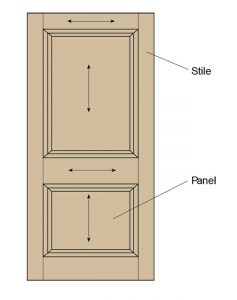

Photo courtesy Woodwork Institute

Solid stock lumber paneling can withstand large changes in humidity when properly designed. Traditional stile and rail paneling takes advantage of longitudinal stability of wood to create a frame around the panel that will hold its dimensions. The solid panel is set within that frame, in a slot or sticking to allow the panel to float. It can expand and contract within the frame without changing the overall dimensions. The same principal is used in stile and rail doors. These methods have been used in millwork for centuries, with excellent results.

Specifications

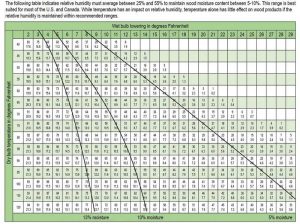

Equilibrium moisture content in wood-based materials is a function of the RH in the surrounding air, with a relatively small influence from the temperature. The NAAWS calls for a moisture content of 5 to 10 percent for most of the United States and Canada (this would correspond with a RH range of approximately 25 to 55 percent). However, for areas with more humid conditions like the southern coastal areas, a higher range of 43 to 79 percent RH is listed. This would produce a moisture content of 8 to 13 percent.

The use of these general ranges can cause problems. There are many micro-climates within the overall areas with significantly different conditions. Coastal areas may be overcast and foggy, and have a higher RH average than areas just a few miles inland. Another consideration is the building use; some medical facilities require higher humidity to avoid static, while others need low humidity. These should be considered when specifying conditions for delivery and installation of millwork. Rather than specifying a standard set of conditions for delivery, storage, and installation of millwork, the local conditions and the building’s design parameters should be considered. Otherwise, the standard range may not be achievable in practice.

Conclusion

Architectural woodwork is an important part of any building project, and when properly executed, can handle a wide range of environmental conditions. NAAWS provides information on dimensional changes, recommended moisture content, and assembly methods. The Wood Handbook published by the United States Department of Agriculture (USDA) is another invaluable reference. There are online calculators for estimating hardwood movement for a given range of conditions. Finally, one must be prepared to work with the millwork fabricator as a partner because their experience and expertise can be a big help.

Mitchel Taylor, CSI, CDT, is director of architectural services at Woodwork Institute. His family has been in the woodworking business since 1929, and he is very familiar with all aspects of the business including design, engineering, production, assembly, and installation of both casework and stairs. Besides inspections, Taylor provides seminars for the American Institute of Architects (AIA), specification review, and technical advice to both design professionals and architectural millwork companies. He can be reached at mitch@woodinst.com.