Principles

‘Life cycle thinking’ opens eyes to a new perspective with more complexity; however, it is a more complete picture by which to make decisions. While the basic concept may sound easy to understand, a true life cycle analysis (LCA) for products can be an involved endeavor, requiring experts to determine the category and datasets by which to analyze both the product and a complex final report.

The LCA models the inputs and outputs at every phase of the product’s life—raw materials extraction/sourcing, manufacturing, installation, use/maintenance, and end of life. Fortunately, Environmental Product Declarations serve as ‘CliffsNotes’ for the report (Figure 1). These EPDs give laypersons the ability to determine the largest eco-impact at a glance, as well as at which phase in the product’s life those impacts occur.

Priorities

Within the entire life cycle, how can one begin to prioritize all the environmental aspects for a building or product? If LEED is used as a gauge, it has prioritized energy as the most important aspect since its inception—weighted with 30 percent of all total points. Further, the aspirational Living Building Challenge (LBC) requires net-zero energy and net-zero water usage.

Finally, another green priority barometer can be found in the Gensler paper, “Design Forecast 2016.” The architecture firm’s forecast cites energy savings as one of its key trends, stating, “The UN and Shell both predict that world demand for potable water, food, and energy will rise 40 to 50 percent by 2030.” As with LEED and LBC, with this benchmark, one sees a marked emphasis on natural resource (energy and water) conservation.

Probing

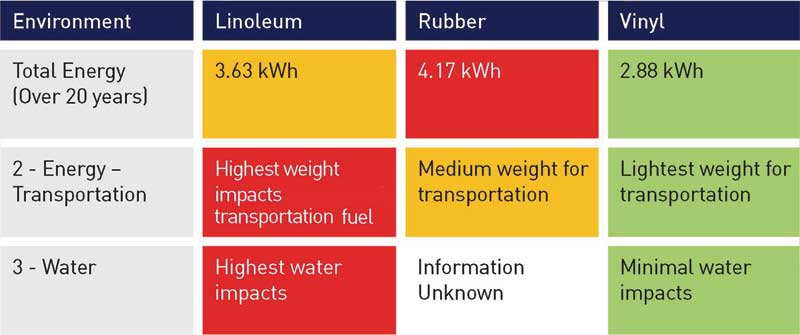

With the shift to life cycle thinking, this article now explores a specific product type—resilient flooring, particularly the best practices based on the priorities of natural resource reduction. In the analysis shown in Figure 2, linoleum, rubber, and vinyl are compared, looking at the EPDs through the lens of the natural resource priorities (i.e. energy and water usage).

Vinyl is shown to be the lowest total energy user—only 69 percent of the highest energy user—rubber. When you analyze the fuel in transportation, linoleum becomes the largest energy-user due to its weight. Overall, linoleum uses the most water in the manufacturing and maintenance process. Therefore, focused on reduction of both energy and water, vinyl performs best. As a general rule, side-by-side assessments of life cycles should be done carefully as there are varying data inputs and methods. Overall, this analysis demonstrates eye-opening outcomes when considering general LCA comparisons of natural resource reduction.

Practice

How does one take this new life cycle thinking from paper to practical reality? One of the forerunners to quite literally write the book on green best practices and share it with the entire building industry was the firm HOK, with its The HOK Guidebook to Sustainable Design. (A third edition is scheduled for this fall.)

In less than 30 months, HOK designed and constructed 511,000 m2 (5.5 million sf) of complex space across 27 buildings for the King Abdullah University of Science and Technology (KAUST) in Thuwal, Saudi Arabia. The campus features 185,800 m2 (2 million sf) of laboratory space spread across four interconnected, 46,450-m2 (500,000-sf) buildings, with flexible building floor plates to accommodate virtually every lab type, according to HOK.

The mission upheld by KAUST’s internationally renowned scientists is “to address humanity’s most urgent scientific challenges related to energy and the environment.” The group also conducts interdisciplinary research that pursues sustainable solutions for water, energy, and food.