Minding your sustainability Ps & Qs: Understanding product life cycle of resilient floorcoverings

by Katie Daniel | June 30, 2016 11:01 am

by Holley Henderson, LEED Fellow

For nearly 20 years, the U.S. design and construction community has largely focused on single-dimension green attributes of building materials. Most practitioners, with hurried schedules and product specifications up to their eyeballs, look for two primary green features—recycled content and low-emitting materials. However, that is now changing.

Unsurprisingly, recycled content and low-emitting materials are currently the most commonly sought Materials & Resource (MR) and Indoor Environmental Quality (EQ) credits in v3 of the Leadership in Energy and Environmental Design (LEED) program. A simple concept, recycled content in particular is a smart, strategic start; it is easy to visualize and comprehend. In the very near future, however, design professionals will need to know much more about what makes a product truly sustainable.

This article uses a Ps and Qs motif in its focus on resilient floorcoverings and life cycle; it combines eight ‘Ps’ for consideration, along with questions (i.e. ‘Qs’) for design/construction professionals to ask themselves or manufacturers when selecting these products.

Perspective

Thanks to the U.S. Green Building Council’s (USGBC’s) juggernaut of influence, LEED has more than met its goal of market transformation since it was introduced 16 years ago. However, there is currently a shift underway to LEED v4, which is estimated to change more than 40 percent of the technical requirements. With LEED v4, specifiers will no longer be able to dismiss the entire product life cycle. One of the best ways to quickly assess life cycle impacts is via Environmental Product Declarations (EPDs).

The U.S. industry is saturated with the original concepts, making now a good time to upgrade the one-dimension ‘silo’ paradigm. The February 2016 issue of USGBC+[1] reported “about 44 percent of all square footage pursuing LEED certification [is] falling outside the U.S. That growth is not confined to one or two specific geographic regions or economic zones, but is spreading far and wide globally.” LEED v4 brings the bar up and gives a common goal to the building industry worldwide.

Overall, the global community has deeper roots in understanding and holding a higher standard for green building. For example, 10 years ago, European countries developed the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) standards to address the impact of chemical production and use on human health and the environment. Hoping to create a similar organization or standard in the United States, USGBC has made REACH one of the new compliance paths available only to international projects in LEED v4 MR Credit, Building Product Disclosure and Optimization–Material Ingredients (Option 2). This allows products to be eligible for credit if the ingredients do not meet REACH criteria for “substances of very high concern.” The behemoth ‘market transformation ship’ is slowly making the turn to life cycle thinking and health. What exactly does this mean, however?

Principles

‘Life cycle thinking’ opens eyes to a new perspective with more complexity; however, it is a more complete picture by which to make decisions. While the basic concept may sound easy to understand, a true life cycle analysis (LCA) for products can be an involved endeavor, requiring experts to determine the category and datasets by which to analyze both the product and a complex final report.

The LCA models the inputs and outputs at every phase of the product’s life—raw materials extraction/sourcing, manufacturing, installation, use/maintenance, and end of life. Fortunately, Environmental Product Declarations serve as ‘CliffsNotes’ for the report (Figure 1). These EPDs give laypersons the ability to determine the largest eco-impact at a glance, as well as at which phase in the product’s life those impacts occur.

Priorities

Within the entire life cycle, how can one begin to prioritize all the environmental aspects for a building or product? If LEED is used as a gauge, it has prioritized energy as the most important aspect since its inception—weighted with 30 percent of all total points. Further, the aspirational Living Building Challenge (LBC) requires net-zero energy and net-zero water usage.

Finally, another green priority barometer can be found in the Gensler paper[2], “Design Forecast 2016.” The architecture firm’s forecast cites energy savings as one of its key trends, stating, “The UN and Shell both predict that world demand for potable water, food, and energy will rise 40 to 50 percent by 2030.” As with LEED and LBC, with this benchmark, one sees a marked emphasis on natural resource (energy and water) conservation.

Probing

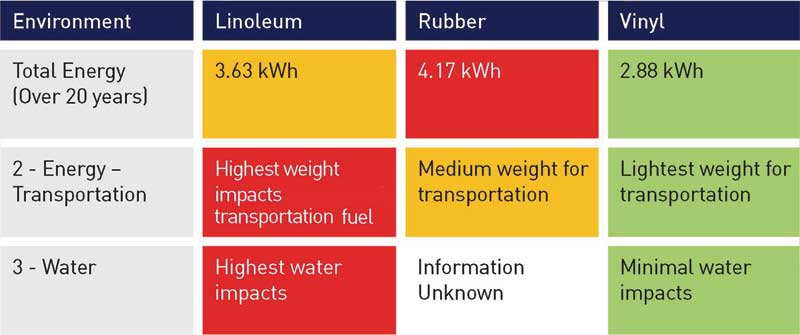

With the shift to life cycle thinking, this article now explores a specific product type—resilient flooring, particularly the best practices based on the priorities of natural resource reduction. In the analysis shown in Figure 2, linoleum, rubber, and vinyl are compared, looking at the EPDs through the lens of the natural resource priorities (i.e. energy and water usage).

Vinyl is shown to be the lowest total energy user—only 69 percent of the highest energy user—rubber. When you analyze the fuel in transportation, linoleum becomes the largest energy-user due to its weight. Overall, linoleum uses the most water in the manufacturing and maintenance process. Therefore, focused on reduction of both energy and water, vinyl performs best. As a general rule, side-by-side assessments of life cycles should be done carefully as there are varying data inputs and methods. Overall, this analysis demonstrates eye-opening outcomes when considering general LCA comparisons of natural resource reduction.

Practice

How does one take this new life cycle thinking from paper to practical reality? One of the forerunners to quite literally write the book on green best practices and share it with the entire building industry was the firm HOK, with its The HOK Guidebook to Sustainable Design. (A third edition is scheduled for this fall.)

In less than 30 months, HOK designed and constructed 511,000 m2 (5.5 million sf) of complex space across 27 buildings for the King Abdullah University of Science and Technology (KAUST) in Thuwal, Saudi Arabia. The campus features 185,800 m2 (2 million sf) of laboratory space spread across four interconnected, 46,450-m2 (500,000-sf) buildings, with flexible building floor plates to accommodate virtually every lab type, according to HOK.

The mission upheld by KAUST’s internationally renowned scientists is “to address humanity’s most urgent scientific challenges related to energy and the environment.” The group also conducts interdisciplinary research that pursues sustainable solutions for water, energy, and food.

The campus is Saudi Arabia’s first LEED-certified project and, at the time of its certification, the world’s largest LEED Platinum project. In 2011, R&D Magazine[3] awarded it ‘Lab of the Year’ status, reporting:

KAUST contains just about every modern lab concept known today. Just a few of the notable features include interchangeable lab neighborhoods, changeable lab support zones, grid planning, kit-of-parts lab furniture, walkable interstitial space, overhead lab services, MEP systems integrated with lab grid, heat recovery wheels, lab visibility/transparency, collaboration spaces, simple and large circulation spines, high-height pilot areas and lab daylighting.

Benjamin Bachman, the CEO and managing director of a U.S.-based resilient floor manufacturer, recalls the conversation with the HOK design team and contractor, Saudi Oger, who discussed flooring for the KAUST campus.

“Originally, when I met with the team, the KAUST high-sustainability goals were a catalyst to prioritize product attributes by LEED v3 points contribution, such as maximizing recycled content,” he says. “There was further discussion about selection criteria, such as using the best high-traffic resilient floor for laboratory usage, using a product that could last 20 years, and using a product that requires no waxing. In the final analysis, a product was installed to accomplish both the sustainability and performance goals.”

“Now with LEED v4, we can tell a much more comprehensive story about the life cycle and ingredients in our products, which include products that go beyond recycled content and low-emitting aspects. From the beginning, each phase of the product is considered, including saving on natural resources (energy/water) to maintenance without harsh chemicals, as well as the durability for a good long life,” Bachman continues. “We are looking forward to LEED v4 revealing to the building community more about how products relate to the environment and health.”

Pioneer

As mentioned, energy and water savings may be common high priorities, but they are not the full measure of a material. Perhaps a cutting-edge client has other environmental priorities, such as bio-based material ingredients—that is, commercial or industrial products (other than food or feed) significantly composed of biological products, renewable agricultural materials, or forestry materials. As a specifier, one must look to the neutral green expert(s) and their recommendations with respect to product manufacturers, investing in this particular field’s research and development.

One of the most respected resources for green building research, resources, and products, BuildingGreen’s Environmental Building News (EBN) highlighted Healthy Building Network’s (HBN) analysis of alternatives to phthalate plasticizers in 2014. HBN is another recognized independent green material research resource that analyzes environmental, health, and social outcomes. It found certain proprietary bio-based plasticizers stood out as having the fewest environmental and health impacts.

Perpetual

Ideally, all the products specified are put into buildings we occupy in the perpetual loop of reuse. A visionary specifier goes beyond identifying the life cycle analysis and examines the product history, as well as the future innovation forecast. Although the industry is transitioning from recycled content to life cycle thinking, this does not mean companies are forgetting where they came from.

In analysis, one often finds reused or recycled content to be better for the overall life cycle. It is important to consider products that include a minimum percentage of recycled content across their entire product line, as well as those that have the ability to be 100 percent recycled or reused.

Purpose

One of the new big green trends is transparency, from the macro to the micro. This can be translated to the manufacturers with whom the project team partners. Companies are made up of people focused on a purpose. It is critical to ask questions when collaborating with outside companies and organizations to determine their business values and environmental ethos.

Conclusion

As design professionals open the curtain to expand their specifying perspective to encompass a more holistic view of what makes a green building material, new guiding principles and priorities are developed. Decision-making is honed through probing—when this yields better results, we incorporate it into our proven best practices. In the big picture, we reveal part of our perpetual search for meaning in our work and we find our purpose by creating spaces that consider the practical life cycle of products by leaving lighter footprints on our planet.

| PRACTICAL: THE NINTH ‘P’ |

|

Top eight green best practices + questions to ask BP #1: Perspective BP #2: Principles BP #3: Priorities BP #4: Probe BP #5: Practice BP #6: PioneeR BP #7: Perpetual BP #8: Purpose

Suggested resource: Learn about Corporate Sustainability Reporting (CSR) within the Global Reporting Initiative (GRI) Framework. Examples can be found in a search at globalreporting.org[9]. |

Holley Henderson, LEED Fellow, is a sustainability consultant for several global building owners, architects, contractors, and product manufacturers, including Gerflor USA. With more than 15 years of industry experience, she has led several ‘firsts,’ including the first LEED-CI project in the United States (Platinum) and China (Gold), as well as, the first LEED project in Thailand. Henderson has served the U.S. Green Building Council (USGBC) in many capacities at the national level, including (past) chair of the Market Advisory Committee and LEED-CI Core Committee. She wrote the book, Becoming a Green Building Professional. Henderson can be contacted through www.holleyhenderson.com[10]

- USGBC+: http://plus.usgbc.org/global-leed

- Gensler paper: http://www.gensler.com/design-thinking/publications/design-forecast

- R&D Magazine: http://www.rdmag.com/articles/2011/06/%20rising-desert

- www.usgbc.org/education-at-usgbc: http://www.usgbc.org/education-at-usgbc

- “EPD: Intro to Environmental Product Declaration.”: http://www.youtube.com/watch?v=XAYq3N3Cj9I

- cdn.callisonrtkl.com/: http://cdn.callisonrtkl.com/%20wp-content/uploads/sites/1/2016/04/sustainability-report-2015-5.pdf

- GreenBiz.com: http://GreenBiz.com

- www.designforreuse.com/pdf/Primer-Online.pdf: http://www.designforreuse.com/pdf/Primer-Online.pdf

- globalreporting.org: http://globalreporting.org

- www.holleyhenderson.com: http://www.holleyhenderson.com

Source URL: https://www.constructionspecifier.com/minding-your-sustainability-ps-qs-understanding-product-lifecycle-of-resilient-floorcoverings/