Moisture management for tall wood buildings

by arslan_ahmed | December 21, 2022 9:00 am

[1]

[1]By Alex Lukachko and Graham Finch, P.Eng.

Mass timber structures are entering the discussion for many projects in North America, and increasingly for taller buildings. This is, in part, due to recent code changes allowing for combustible construction in taller structures. However, interest in the industry is driven by a larger trend—the need for fast action to mitigate climate change.

For many in the industry, the trend toward taller mass timber structures is exciting. These are the “buildings of the future” that, if designed for low-energy use, can directly contribute to climate change mitigation efforts by reducing both operating and embodied carbon. Additionally, the use of wood in buildings gives designers a direct way to connect occupants to the natural world, and perhaps providing additional motivation for a sustainable future. There are a lot of reasons to feel good about tall wood buildings.

For others, the challenge of constructing tall wood buildings might just be too great. The taller we build, the more uncertainty. Not only does one have to address new design approvals and construction processes, but also there are some basic and pressing questions, such as what happens if the wood burns or if the material gets wet? These are important questions to address.

Fire safety in tall wood buildings

First, the fire question. Interested parties will see governments, industry groups, researchers, design professionals, and suppliers are all contributing to fire performance assessments, to the planning of integrated fire protection strategies, and to the development of new regulations and guidelines for tall mass timber buildings. Many of the challenges are already known—in all tall buildings, design professionals regularly balance the combustibility of building materials, finishes and furnishings, human activities, risk of mechanical failure, etc., with the efficacy of fire protection strategies. These challenges are not unique to tall mass timber buildings.

Moisture and tall wood buildings

Wood—like many materials we build with—can get wet, but there are limits that designers and specifiers need to be aware of. For example, when wood moisture content rises, there may be dimensional changes that are significant enough to impact adjacent materials and components. Certain types of engineered mass timber components may experience warping or irreversible dimensional changes as moisture content increases. When moisture content is above 19 percent, the characteristics of the wood elements may change significantly enough to impact structural capacity. This may be a concern at bearing points and where fasteners are located. Above approximately 25 percent moisture content, moisture may be present in liquid form and allow for progression of decay and fungi and mold growth. Many of these problems are only a concern in tall buildings if high moisture conditions persist, but even short-term exposure can lead to unwanted wetting and associated staining.

In practice, therefore, we want to keep mass timber relatively dry. Components are expected to arrive at the building site at less than 12 percent moisture content. The goal then is to limit moisture content to below 16 percent until the building is fully enclosed and the environmental control systems are operating. Designers are encouraged to use these limits as general guides, but it is important to note each species of wood—and each type of engineered wood component—has a different response to moisture. Additionally, the actual moisture content should be expected to change over time in response to changing environmental conditions (See the sidebar below “Changing Moisture Conditions for Mass Timber Elements from Construction to Occupancy”).

| Changing Moisture Conditions for Mass Timber Elements from Construction to Occupancy |

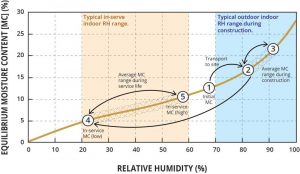

| Figure 1 (page 24) plots the equilibrium moisture content (m.c.) of a mass timber element against the relative humidity (RH) of the surrounding environment. Overlaid on this plot is a storyline showing the movement of wood through different moisture regimes during construction and operation. Dot #1 is the approximate starting point: perhaps 12 percent moisture content as the component leaves the manufacturer. As the element is transported to the construction site, outdoor conditions (in the blue range) are at a higher RH. With weeks of exposure, the mass timber element’s moisture content moves higher, maybe as high as 20 percent m.c. between dots #2 and #3. Construction is completed, the building closed in, and operating conditions in the building are established (the light orange range). The mass timber moisture content moves downward as it comes into equilibrium with the interior conditions, at dot #4. Afterward, during normal operation, seasonal changes in RH will move the mass timber m.c. upward and downward within the operating range, between dots #4 and #5. All of this is normal and will occur without moisture-related problems. In fact, the response of wood to the environmental conditions capacity represents an ability to accommodate changes—a built-in safety—as long as the conditions do not range too high or too low.

|

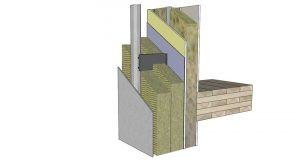

| Figure 1 Curtain wall (left) and insulated light metal frame wall (right) concept enclosures. Images © RDH Building Science Inc |

Mass timber structures are subject to moisture in the following ways:

- Before or during construction:

◦ manufacturing◦ wetting during storage◦ wetting during transportation◦ after erection of the structure and

before enclosure

- During operation:

◦ bulk water leakage through the enclosure (a significant design consideration for tall buildings with higher wind-driven rain loads)

◦ accidents (plumbing, sprinklers)

◦ changes to interior environmental conditions (temperature, humidity) and potential accumulation of moisture via air leakage or vapor diffusion.

Most of the sources listed above can be controlled through careful design of the building enclosure to minimize bulk water leakage, avoid accumulation by air leakage or vapor diffusion, and allow for some drying to the interior or exterior as environmental conditions allow. The period of time the structure is unenclosed during construction is the highest risk of moisture exposure for the structure. Although tall buildings present a smaller horizontal “footprint” to rain, wind-driven rain has access to a greater number of floors and, given the longer construction time for tall structures, the exposure may be significant until the building enclosure is in place.To address the concerns above, the author’s firm has the following recommendations for tall mass timber buildings.

Enclose the structure quickly

Mass timber structures assemble and are loadbearing more quickly than those that are concrete-framed—similar in speed to steel. Speed of building enclosure construction is, therefore, a crucial factor in the protection of wood from moisture, reducing the amount of time structural elements are exposed to the weather. To fully protect the mass timber elements, construction of exterior wall and roof elements should be planned to enclose each floor level quickly as the erection of the primary structure proceeds. This can be done with temporary protection (scaffolding and tarping, for example) but the costs may be significant. Prefabrication of wall components is recommended to meet this “fast enclosure” objective.

Unitized curtain wall or insulated precast concrete systems are good choices with robust technical details, good design support, and a mature procurement process. These systems, however, may not easily meet increasingly stringent project requirements for low operating and embodied carbon. Other options, such as light steel frame, light wood frame, or cross-laminated timber (CLT) panels (Figure 1), are possible, but may require additional design work and planning, including:

- detailing of joints and interfaces with other enclosure systems.

- coordination of multiple suppliers offsite (frame, insulation, cladding, glazing systems).

- some level of work onsite to complete critical seals and finishes.

| Figure 2 Installation process (left) and installed wall panels (right) in an 18-story mass timber building. Photos © RDH Building Science Inc. |

The challenges listed above have been successfully addressed for several tall mass timber projects in North America. For example, Figure 2 shows the installation of large frame panels with windows and cladding pre-installed offsite. No finishing work was required on the exterior of this building, but final air and water seals, additional thermal insulation, and interior finishes were installed from the interior after panels created a watertight exterior enclosure.

Protect horizontal surfaces

[3]

[3]Floors and roofs are at elevated risk of water penetration during construction. However, strategies can be employed for both types of assemblies to minimize exposure.For roof assemblies, a fully adhered membrane installed by the supplier before the panel leaves the production facility can provide protection against moisture during transport and storage (Figure 3).

This membrane can also serve as a temporary roof membrane after the panel has been installed. The author’s firm recommends “designing in” this protection layer in the place of the deck-level air control layer (commonly referred to as the roof vapor retarder) in the finished assembly.

Floor decks may also be exposed to rain for shorter periods during construction but are still subject to saturation of the mass timber and staining of the exposed surfaces (Figure 4).

[4]

[4]Recommendations for protection for CLT, glue-laminated (glulam) timber, and nail-laminated timber (NLT) floor panels differ slightly. Due to the tightly assembled panel construction, CLT and dowel-laminated timber (DLT) panels are less open to bulk water penetration. A wax-based sealer on the end grain with a low permeance polyurethane coating on the top surface of the panel will generally be enough protection if rain exposure can be minimized. The author’s firm has tested several options and recommends the following:

- apply the coating in the factory, testing if necessary to ensure adequate thickness (avoid site installation).

- apply waxed-based coating to all exposed edges, including internal service penetrations and where fasteners and anchors will be installed.

- observe the coating manufacturer’s installation instructions for moisture content of the wood (often best controlled at the factory) and surface preparation.

- include requirements for construction-phase moisture protection.

Glulam floor panels may need less protection because of the tight wood-to-wood panel construction, and many suppliers use a light sealer to protect the wood during shipping. Onsite taping of panel joints and internal service penetrations is recommended.

With more open joints between parallel laminations, NLT panels require more protection than CLT and glulam. Water penetrating between NLT laminations and absorbing into the wood mid-panel depth is more difficult to dry than moisture adsorbed by the upper or lower surfaces. NLT panels often include a cover layer of plywood or oriented strand board (OSB) on the upper surface and the joints in this layer can be taped after installation to provide a continuous water-resistant layer. Some OSB sheathing products are designed with an integral coating and can provide more resistance to moisture. This type of product could be specified from the outset if construction is likely to occur in a season with high precipitation, or the design and construction team may consider changing to this type of product to enhance moisture protection if the construction schedule moves towards a rainier period of the year. If heavy rain is unavoidable during the construction of the floor levels, a factory-applied coating, sealer, or membrane can be added to the cover layer’s upper surface (Figure 5).

[5]

[5]The added resistance to water penetration provided by the steps described above will also help control bleed water from concrete or gypcrete floor toppings. Further, each of these measures provides a built-in protection against accidental exposure to water during operation of the building.When the full construction schedule for a tall building is considered, a reasonable approach to protection for horizontal surfaces is to create multi-story compartments rather than addressing every floor. This allows for “break points” to be planned into the schedule to accommodate weather and schedule delays: construction proceeds to designated levels where a complete water-resistant layer is installed before continuing the build. Weather events affect only the uppermost compartment. This strategy also allows for the air- and water-tight compartments to proceed with interior work, and probably more importantly, have active temporary fire protection systems during construction.

Design assemblies for long-term protection of the mass timber structure

Mass timber structures will have a long service life if kept within stable temperature and moisture conditions—the objective is to create and maintain warm and relatively dry conditions. The author’s firm recommends an enclosure to the exterior of the primary structure that passes over and encloses each floor level. This approach minimizes unprotected structural elements, and, as noted above, also helps address fast weathertightness of the building during construction. The design objective will be to keep all mass timber elements within, and protected by, the thermal enclosure.

Designing mass timber assemblies to allow for in-service drying is an important long-term protection against unexpected water intrusion. Generally, roof and floor assemblies should be designed so that drying is possible to at least one side of the assembly.

Wood undergoes shrinkage as it comes into equilibrium with the conditioned interior environment of the building. Tall wood structures have the potential (depending on framing and the specific products used) to undergo a significant amount of drying shrinkage. Although the overall shrinkage of the structural frame will be considered in the structural design, it is critical to look at how this movement will affect joints and transitions between materials and systems, and special attention should be paid to interfaces with building elements (such as concrete elevator cores) that will move differently over time. It is important to note unexpected wetting during construction may lead to dimension changes as the building dries.

Developing a construction moisture management plan

The plan to manage exposure to moisture during construction will ultimately be the responsibility of the constructor. However, as discussed above, the plan to protect mass timber components (e.g. using a prefabricated enclosure to quickly enclose the structure) does inform design decisions and should impact construction sequence planning, both at a high level (time of year) and in sequencing trades onsite. The author’s firm suggests the creation of a draft plan early in the detailed design process to help establish requirements that will later become part of the general conditions for the project. At a minimum, the draft moisture management plan should include:

- identifying moisture risks during manufacturing, transportation, storage, and construction, with a statement of impact for each construction schedule and long-term performance of the building.

- specifying measures to mitigate these risks, including identification of parties responsible for each.

- considering both passive (for example, factory-applied coatings, or tenting the structure) and active measures (such as a protocol for removal of ponding water).

- processing for documentation and reporting.

From experience, the author’s firm suggests placing special emphasis on accountability in this moisture management plan. Mass timber components can absorb water quickly if exposed to standing water.

A discussion about responsibility while standing in a pool of water onsite is the likely result of a poorly developed plan. The plan should include assigned responsibility to specific people and automatic responses to events like high rainfall. It should be made clear failure to attend to moisture protection measures—both installation of passive elements and active responses to wetting events—will result in construction delays as wet wood is dried to safe moisture content levels, and possibly remedial work to remove staining or mold growth on

mass timber elements meant to be exposed as an interior finish.

Conclusion

It is true there are many challenges to overcome as more tall mass timber buildings are constructed. Protection from moisture before and during construction, and then through the operational life of the building, is an important part of realizing the long-term benefits of a mass timber structure. The industry has good processes in place for recognizing and mitigating risk through building enclosure design and then coordination between design and construction teams. At a minimum, the author’s firm recommends the following four steps be taken for the building enclosure design and construction:

- enclose quickly—prefabrication of wall elements allows enclosure at the same speed as erection of the structure.

- protect horizontal surfaces—methods should be chosen based on the type of mass timber and the risk of exposure during construction.

- design assemblies for long-term protection—use a rainscreen approach, continuous insulation (ci) to the exterior of the mass timber and provide for drying. (Much more information about building enclosure design for mass timber buildings

can be found in the reference provided in the following paragraph.) - develop a construction moisture management plan—many people will be involved; assign responsibilities to specific people and identify triggers for automatic response.

For further information, consult the CLT Design Guide published by FP Innovations, the NLT Canada Design and Construction Guide available at ThinkWood.com, and the 2022 Technical Guide for the Design and Construction of Tall Wood Buildings in Canada.1 Visit the technical library of RDH Building Science for current research, case studies, and related presentations.2

Notes

1 The CLT Design Guide can be accessed at web.fpinnovations.ca/clt. The NLT Canada Design and Construction Guide is available at www.thinkwood.com/mass-timber/nlt, and the Technical Guide for the Design and Construction of Tall Wood Buildings in Canada can be found on https://web.fpinnovations.ca/tallwood/.

2 Visit www.rdh.com/technical-library.

Authors

Alex Lukachko is an assistant professor at the John H. Daniels Faculty of Architecture, Landscape, and Design at the University of Toronto. At the time of writing, he was also a principal at RDH Building Science Inc. He works on the research and development of future building enclosure systems, and the design of high performance, low-carbon mass timber buildings. He can

Alex Lukachko is an assistant professor at the John H. Daniels Faculty of Architecture, Landscape, and Design at the University of Toronto. At the time of writing, he was also a principal at RDH Building Science Inc. He works on the research and development of future building enclosure systems, and the design of high performance, low-carbon mass timber buildings. He can

be reached at alex.lukachko@daniels.utoronto.ca.

Graham Finch is a principal at RDH Building Science Inc., based in Victoria, British Columbia. He has led the firm’s building enclosure consulting services on many larger mass timber buildings in North America. Finch leads research related to mass timber moisture management, and has co-authored many industry best practice guides on building enclosures for mass timber buildings. He can be reached at gfinch@rdh.com.

Graham Finch is a principal at RDH Building Science Inc., based in Victoria, British Columbia. He has led the firm’s building enclosure consulting services on many larger mass timber buildings in North America. Finch leads research related to mass timber moisture management, and has co-authored many industry best practice guides on building enclosures for mass timber buildings. He can be reached at gfinch@rdh.com.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/12/Brock-April-2017-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/12/Figure-X-MC-graph.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/12/Figure-3-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/12/Figure-4-Wetting-of-CLT.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/12/Figure-5-Taped-membrane-over-NLT.jpg

Source URL: https://www.constructionspecifier.com/moisture-management-for-tall-wood-buildings/

[2]

[2]