by Jason Spangler

Moisture presence in concrete slabs can cause problems for all types of floors, including carpeting, wood, stone, poured polymeric, and resilient finish. Too much moisture can cause floorcoverings to cup, buckle, blister, and discolor, and these problems can occur days, months, or years after installation. In other words, excess moisture adversely affects the assembly’s short- and long-term viability. It can also affect any type of project, whether commercial, residential, or industrial. Specification of a reliable, accurate moisture measurement method is vitally important for ensuring a successful outcome.

Concrete is said to ‘breathe’ with the environment—that is, it allows moisture to move in and out of the slab, depending on the ambient conditions. When evaluating a problem, it is therefore necessary to understand the moisture condition inside the concrete and not just at the surface. Unfortunately, the latter is historically where most moisture testing has been done.

Moisture can be found in slabs above grade. These can be elevated structural slabs or concrete in steel decks, such as a building that is framed in corrugated or ribbed steel sheets supporting the concrete floor (Figure 1). Not only do these slabs have construction water that needs to evaporate, but they can also be impacted by the ambient relative humidity (RH) in the room. On hot, humid days, moisture goes into the concrete; on drier days, it comes out. Rain, snow, or fog can also get onto the slab.

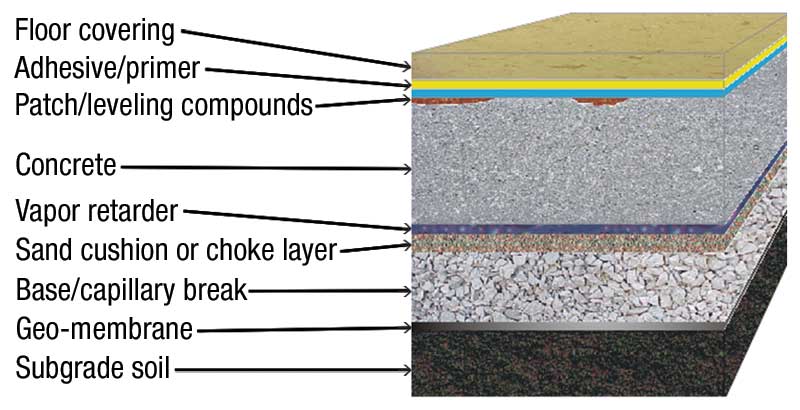

In slabs below grade, moisture comes in the form of sub-slab vapor. This is the predominant cause of moisture problems—the culprit is not liquid water below the floor that gets in contact with the slab from the underside, but rather moisture vapor in the soil that comes up into the slab. This is the primary reason for needing a sub-slab vapor retarder.

Image courtesy CTLGroup and Wagner Meters

In the slab itself is the batch water (the ratio of water to cement that was originally batched into the concrete), which includes ‘water of convenience’ to make concrete placing and finishing easier. This is one of the main factors determining how long it takes a concrete floor to dry.

Most floors are poured on grade (i.e. slabs-on-ground), which means the concrete slab’s surface is the primary way for the moisture within to escape. As moisture evaporates through the surface, the moisture deeper in the slab moves toward the surface. This creates a moisture gradient that is drier on the surface and wetter toward the bottom.

Moisture equilibrium: Why is it important?

When flooring is installed over the slab, this essentially creates a seal so moisture can no longer escape from the surface. Over time, the moisture condition throughout the slab tends to equalize, creating what is called a ‘moisture equilibrium.’ This point equates to the true, long-term moisture condition of the slab; it is a critical factor in determining the installed floor’s long-term viability. Knowing this, it is important to specify a measurement method that can reliably and accurately indicate the moisture condition at the point of equilibrium.

The two measurement methods most commonly used in the United States are:

- the calcium chloride (CaCl2) test, which is standardized as ASTM F1869, Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride; and

- the in-situ RH test, which is standardized as ASTM F2170, Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In-situ Probes.

However, only the latter of these can be relied on for consistent, accurate test results closely related to the critically important point of moisture equilibrium.

Scientific studies in recent decades have shown the slab’s moisture condition (and how it affects installed flooring) can best be measured by looking at the RH deep down in the concrete with a probe set into the floor slab. Since 2002, the in-situ RH moisture test, as described in ASTM F2170, has been increasingly favored over ASTM F1869 as the ‘gold standard’ for moisture testing.