Hygienic Ceilings: Standards and guidelines

Photo courtesy Ceilume

by Ed Davis, David Condello, Michael Chusid, RA, FCSI, CCS

The January 2017 issue of The Construction Specifier included the authors’ in-depth look at the world of hygienic ceilings, “Hygienic Ceilings: Keeping it Clean Overhead.” In this complementing web feature, the authors examine various regulations and guidelines for constructing and maintaining ceilings in facilities with hygienic requirements.

What’s in a word?

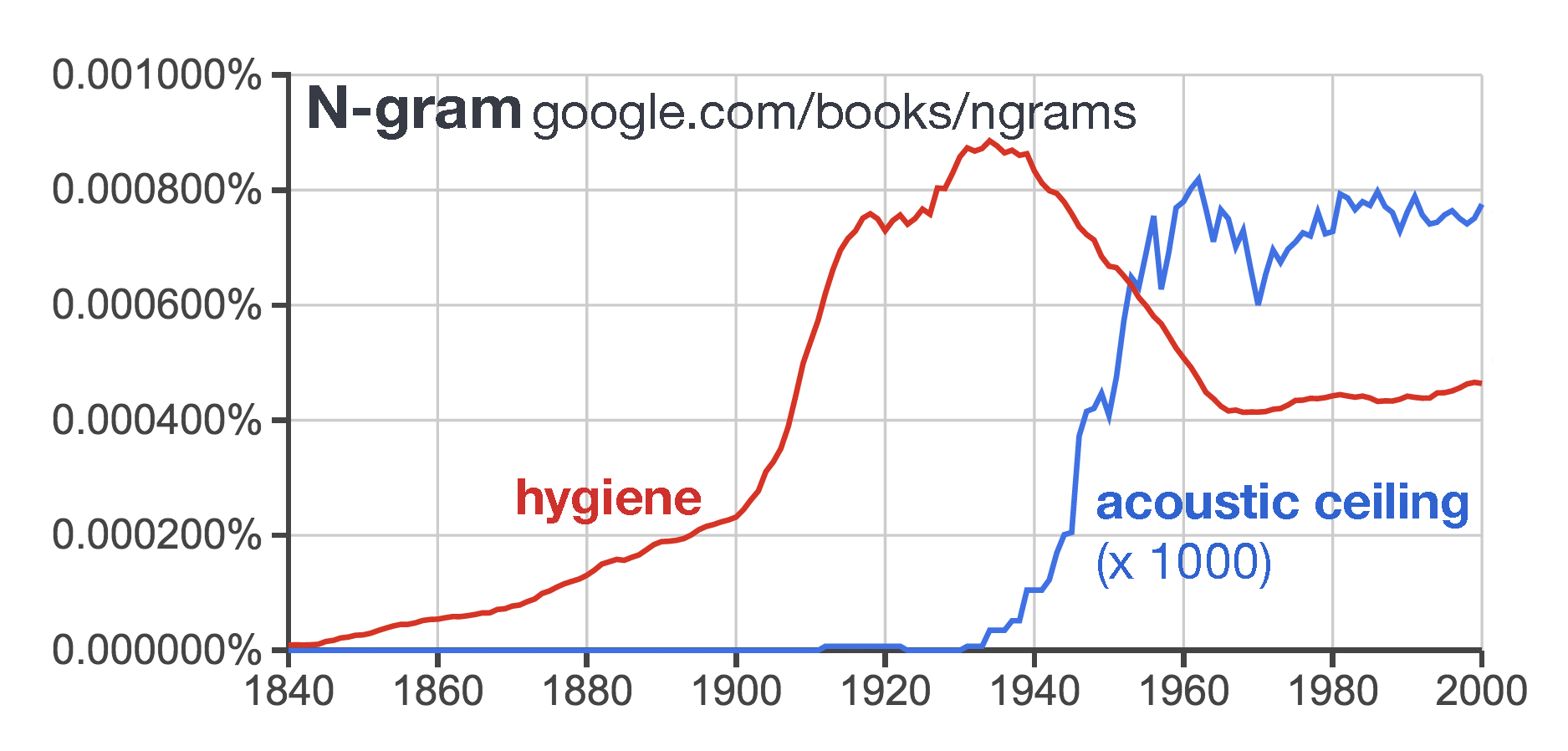

The n-gram graph below traces the frequency of the word ‘hygiene’ in English-language books, offering insight into changing behavior. The word did not start trending until the second half of the 19th century, during the epoch when Pasteur and others developed the germ theory of disease. With the realization cleanliness reduces disease, the richly decorated surfaces of the Victorian Age began evolving into the less fussy styles of the Edwardian Age, and then the austerity of the Modernist architects.

The decline in the term’s use becomes pronounced shortly after 1928, when Fleming discovered penicillin. It is interesting to note the decline of references to hygiene occurs simultaneously with the growing interest in ‘acoustical ceilings.’ Prior to the advent of acoustical ceilings, most ceilings were relatively easily cleaned hard surfaces such as plaster, tin, or painted wood. Perhaps the miracles of modern medicine made it possible for people to overlook hygiene and use difficult-to-clean ceilings that potentially release fibers and support mold.

Hospitals

The Facility Guidelines Institute’s (FGI’s) 2014 Guidelines for Design and Construction of Hospitals and Outpatient Facilities covers the topic under 2.1-7.2.3.3−Ceilings. In the locations listed below, ceilings must be cleanable with routine housekeeping equipment and not create ledges or crevices:

- areas occupied by patients;

- clean workrooms;

- clean supply rooms;

- soiled workrooms;

- soiled holding rooms;

- nourishment areas and rooms;

- food and nutrition services facilities;

- pharmacy areas;

- central services areas; and

- laboratories.

For endoscopy procedure (and instrument processing) rooms and decontamination rooms, ceilings must be crevice-free and be able to withstand cleaning with chemicals. Lay-in ceiling need to be gasketed or clipped down, as well as cleanable. Perforated, tegular, serrated, cut, or highly textured panels are not permitted in these areas.

Photo courtesy Instor Solutions Inc.

For semi-restricted areas such as clean corridors, central sterile supply spaces, specialized radiographic rooms, and Class A operating rooms, the ceiling must be smooth, scrubbable, non-absorptive, non-perforated, capable of withstanding cleaning with chemicals, and without crevices. A lay-in ceiling must be gasketed, or each ceiling tile shall weigh at least 4.9 kg/m2 (1 lb/sf). Perforated, tegular, serrated, cut, or highly textured panels are not permitted.

Monolithic ceilings are required for restricted areas, such as operating rooms. Airborne-infection isolation rooms must be sealed to prevent air infiltration.

For food/nutrition service and laundry areas, lay-in ceilings require a non-corrosive grid, and panels need to be smooth, scrubbable, non-absorptive, non-perforated, capable of withstanding cleaning with chemicals, and weigh at least 4.9 kg/m2.

Additional FGI requirements include:

- 2.1-8.4.2.6−where drainage piping is installed above ceilings of nurseries, food-handling areas, central services, and electronic data processing areas, the piping must have special provisions (e.g. drip pans) to protect spaces below from leakage and condensation (this provision can be addressed by pan-shaped thermoformed ceiling panels);

- 2.2-2.10−neonatal intensive care units require ceilings to be non-friable; and

- 2.5-7−in patient areas, fire sprinklers must be designed to minimize patient tampering (a provision that can be addressed by drop-out ceilings).

Food preparation areas

The U.S. Food and Drug Administration (FDA) Food Code states:

6-101.11: ceiling surfaces under conditions of normal use shall be… smooth, durable, and easily cleanable… [and] nonabsorbent for areas subject to moisture such as food preparation areas, walk-in refrigerators, warewashing areas, toilet rooms, mobile food establishment servicing areas, and areas subject to flushing or spray cleaning methods.

The use of drop-out ceilings supports the requirement that:

6-201.12: Utility service lines and pipes may not be unnecessarily exposed.

The use of luminous ceilings supports the requirement that:

6-202.11: …light bulbs shall be shielded… in areas where there is exposed food.

Sanitation Performance Standards Compliance Guide by the U.S. Department of Agriculture (USDA) Food Safety Inspection Service (FSIS) states:

416.2(b): ceilings within establishments must be built of durable materials impervious to moisture and be cleaned and sanitized as necessary to prevent adulteration of product… outside openings must be constructed and maintained to prevent the entrance of vermin, such as flies, rats, and mice.

6-201.11: ceilings shall be designed, constructed, and installed so they are smooth and easily cleanable…

6-201.12: Utility service lines and pipes may not be unnecessarily exposed. Exposed utility service lines and pipes shall be installed so they do not obstruct or prevent cleaning of… ceilings.

6-201.16: ceiling covering materials shall be attached so that they are easily cleanable.

6-202.15: outer openings of a food establishment shall be protected against the entry of insects and rodents by: Filling or closing holes and other gaps along floors, walls, and ceilings…

Comments in the standard raise concern about condensation on areas such as ceilings over open cooking kettles.