Hygienic Ceilings: Standards and guidelines

by Erik Missio | December 27, 2016 11:25 am

Photo courtesy Ceilume

by Ed Davis, David Condello, Michael Chusid, RA, FCSI, CCS

The January 2017 issue of The Construction Specifier included the authors’ in-depth look at the world of hygienic ceilings, “Hygienic Ceilings: Keeping it Clean Overhead.”[1] In this complementing web feature, the authors examine various regulations and guidelines for constructing and maintaining ceilings in facilities with hygienic requirements.

What’s in a word?

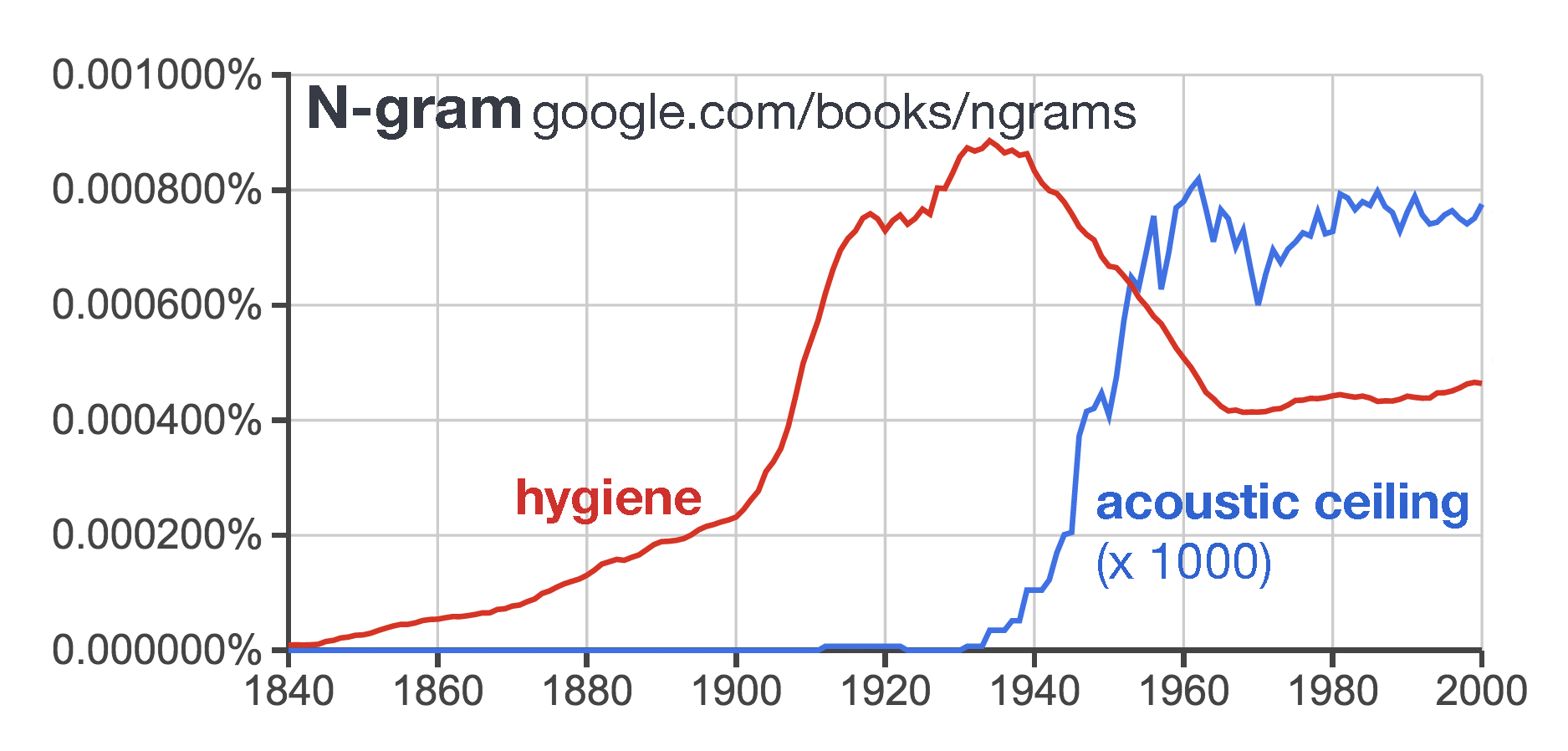

The n-gram graph below traces the frequency of the word ‘hygiene’ in English-language books, offering insight into changing behavior. The word did not start trending until the second half of the 19th century, during the epoch when Pasteur and others developed the germ theory of disease. With the realization cleanliness reduces disease, the richly decorated surfaces of the Victorian Age began evolving into the less fussy styles of the Edwardian Age, and then the austerity of the Modernist architects.

The decline in the term’s use becomes pronounced shortly after 1928, when Fleming discovered penicillin. It is interesting to note the decline of references to hygiene occurs simultaneously with the growing interest in ‘acoustical ceilings.’ Prior to the advent of acoustical ceilings, most ceilings were relatively easily cleaned hard surfaces such as plaster, tin, or painted wood. Perhaps the miracles of modern medicine made it possible for people to overlook hygiene and use difficult-to-clean ceilings that potentially release fibers and support mold.

[2]

[2]Hospitals

The Facility Guidelines Institute’s (FGI’s) 2014 Guidelines for Design and Construction of Hospitals and Outpatient Facilities[3] covers the topic under 2.1-7.2.3.3−Ceilings. In the locations listed below, ceilings must be cleanable with routine housekeeping equipment and not create ledges or crevices:

- areas occupied by patients;

- clean workrooms;

- clean supply rooms;

- soiled workrooms;

- soiled holding rooms;

- nourishment areas and rooms;

- food and nutrition services facilities;

- pharmacy areas;

- central services areas; and

- laboratories.

For endoscopy procedure (and instrument processing) rooms and decontamination rooms, ceilings must be crevice-free and be able to withstand cleaning with chemicals. Lay-in ceiling need to be gasketed or clipped down, as well as cleanable. Perforated, tegular, serrated, cut, or highly textured panels are not permitted in these areas.

Photo courtesy Instor Solutions Inc.

For semi-restricted areas such as clean corridors, central sterile supply spaces, specialized radiographic rooms, and Class A operating rooms, the ceiling must be smooth, scrubbable, non-absorptive, non-perforated, capable of withstanding cleaning with chemicals, and without crevices. A lay-in ceiling must be gasketed, or each ceiling tile shall weigh at least 4.9 kg/m2 (1 lb/sf). Perforated, tegular, serrated, cut, or highly textured panels are not permitted.

Monolithic ceilings are required for restricted areas, such as operating rooms. Airborne-infection isolation rooms must be sealed to prevent air infiltration.

For food/nutrition service and laundry areas, lay-in ceilings require a non-corrosive grid, and panels need to be smooth, scrubbable, non-absorptive, non-perforated, capable of withstanding cleaning with chemicals, and weigh at least 4.9 kg/m2.

Additional FGI requirements include:

- 2.1-8.4.2.6−where drainage piping is installed above ceilings of nurseries, food-handling areas, central services, and electronic data processing areas, the piping must have special provisions (e.g. drip pans) to protect spaces below from leakage and condensation (this provision can be addressed by pan-shaped thermoformed ceiling panels);

- 2.2-2.10−neonatal intensive care units require ceilings to be non-friable; and

- 2.5-7−in patient areas, fire sprinklers must be designed to minimize patient tampering (a provision that can be addressed by drop-out ceilings).

Food preparation areas

The U.S. Food and Drug Administration (FDA) Food Code [4]states:

6-101.11: ceiling surfaces under conditions of normal use shall be… smooth, durable, and easily cleanable… [and] nonabsorbent for areas subject to moisture such as food preparation areas, walk-in refrigerators, warewashing areas, toilet rooms, mobile food establishment servicing areas, and areas subject to flushing or spray cleaning methods.

The use of drop-out ceilings supports the requirement that:

6-201.12: Utility service lines and pipes may not be unnecessarily exposed.

The use of luminous ceilings supports the requirement that:

6-202.11: …light bulbs shall be shielded… in areas where there is exposed food.

Sanitation Performance Standards Compliance Guide [5]by the U.S. Department of Agriculture (USDA) Food Safety Inspection Service (FSIS) states:

416.2(b): ceilings within establishments must be built of durable materials impervious to moisture and be cleaned and sanitized as necessary to prevent adulteration of product… outside openings must be constructed and maintained to prevent the entrance of vermin, such as flies, rats, and mice.

6-201.11: ceilings shall be designed, constructed, and installed so they are smooth and easily cleanable…

6-201.12: Utility service lines and pipes may not be unnecessarily exposed. Exposed utility service lines and pipes shall be installed so they do not obstruct or prevent cleaning of… ceilings.

6-201.16: ceiling covering materials shall be attached so that they are easily cleanable.

6-202.15: outer openings of a food establishment shall be protected against the entry of insects and rodents by: Filling or closing holes and other gaps along floors, walls, and ceilings…

Comments in the standard raise concern about condensation on areas such as ceilings over open cooking kettles.

Occupational health and safety

While the National Institute for Occupational Safety and Health (NIOSH) addresses health and safety of construction personnel in its Maintaining Indoor Environmental Quality (IEQ) during Construction and Renovation[6], its hygienic practices also have a salubrious impact throughout the life of a building:

Construction and renovation projects… can adversely affect building occupants by the release of airborne particulates, biological contaminants, and gases. Careful planning for IEQ and the prevention of exposure during these activities is essential…

Particulate material such as dusts and fibers are likely to be produced during construction and renovation activities. Sources include drywall… Non-toxic dusts are irritants and can exacerbate lung conditions such as asthma and chronic obstructive lung disease…

Materials that contain fibers such as fiberglass composite materials or insulation can irritate the skin, eyes, and respiratory tract when disbursed in the air and/or inhaled…

For all construction and renovation dusts, a plan to minimize exposure should be implemented. Appropriate containment should be in place to prevent disbursement into occupied areas…

Photo courtesy Michael Chusid

Laboratories

Section 4-4−Interior Finishes of the U.S. National Institutes of Health (NIH) Design Requirements Manual[7] states criteria for finish selection include housekeeping and maintenance costs, durability, and aseptic characteristics. Ceilings must be durable, smooth, and easily cleaned, provide ease of maintenance, and be as resistant as possible to the corrosive chemical activity of disinfectants and other chemicals used in the laboratory.

In most areas, ceilings such as washable lay-in acoustical tiles (with smooth, plastic faces) with a square edge (not tegular) on a non-concealed spline must be provided. Exceptions include glassware washing, autoclave rooms, and other areas with high moisture levels, which require special consideration.

Another exception can be found with animal facilities, which require ceilings that are smooth, free of crevices and imperfect junctions with walls, and capable of withstanding scrubbing with detergents, disinfectants, and water under pressure on a frequent basis. Surface-mounted lights and exposed pipes are not permitted in these spaces. Suspended fiber-reinforced plastic (FRP) panels with a heavy-duty aluminum suspension system, gasketed with hold-down clips, are recommended for animal research facilities.

Vivarium ceilings may be constructed of suspended high-density, moisture-resistant gypsum wallboard (GWB) with an epoxy coating. Containment laboratories require monolithic ceilings with chemical-resistant finishes.

In all cases, maximum accessibility to mechanical and electrical distribution systems above ceilings shall be provided.

Pharmaceutical areas

United States Pharmacopeial (USP) 797, Pharmaceutical Compounding−Sterile Preparations[8], includes requirements applying to sterile areas and anterooms:

4.3: The surfaces of ceilings… in a classified area or in a segregated compounding area must be smooth, impervious, free from cracks and crevices, and non-shedding, thereby promoting cleanability and minimizing spaces in which microorganisms and other contaminants can accumulate. Surfaces must be resistant to damage by disinfectants. Junctures between the ceiling and the walls must be coved or sealed to eliminate cracks and crevices where dirt can accumulate. If ceilings consist of inlaid panels, the panels must be impregnated with a polymer to render them impervious and hydrophobic, and they must be sealed… Classified areas and segregated compounding areas must not contain dust-collecting overhangs, such as utility pipes… The exterior lens surface of ceiling light fixtures must be smooth, mounted flush, and sealed. Any other penetrations through the ceiling or walls must be sealed.

Schools

When it comes to schools, the guidelines vary between states. For example, Utah’s Administrative Code Rule R392-200, Design, Construction, Operation, Sanitation, and Safety of Schools[9], makes a general statement that “all school building floors, walls, and ceilings shall be constructed with materials that are durable and easily cleanable.” In addition, toilet and shower rooms’ ceilings “must be constructed of smooth, non-absorbent, easily cleanable materials,” and waste storage room ceilings shall be “constructed with easily cleanable, nonabsorbent, washable materials.” Food service areas must comply with health department regulations.

Good manufacturing practices

Agencies regulating the manufacturing of drugs, medical equipment, food, cosmetics, and other products that affect health have published good manufacturing practices (GMPs), defined by the World Health Organization (WHO)[10] as systems for “ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in… production that cannot be eliminated through testing the final product.” WHO cites contamination as one of the main risks to health.

Photo courtesy Ceilume

FDA and FSIS, for example, require compliance with Current Good Manufacturing Practices (21 CFR § 110.20[b][4])[11] that require construction of manufacturing facilities so ceilings can be kept clean and in good repair. Condensation from fixtures, ducts, and pipes must also be prevented from dripping into clean areas, a requirement that can, in some buildings, be met by locating them above ceiling panels that act as evaporation pans.

Conclusion

Additional requirements may apply to these and other building types. Specifiers should review project requirements with authorities having jurisdiction (AHJs) and consultants with expertise in appropriate areas of hygiene.

Ed Davis is president of Ceilume, a manufacturer of thermoformed ceiling products. He has been responsible for product testing and code compliance. Davis can be reached through www.ceilume.com/pro[12].

David Condello has more than 20 years of experience in construction, and is architectural services manager for Ceilume. He can be contacted via www.ceilume.com/pro[12].

Michael Chusid, RA, FCSI, CCS, is a frequent contributor to this magazine, and received the 2015 The Construction Specifier Article of the Year Award from CSI. He is an authority in building product innovation. Chusid can be reached through www.chusid.com[13].

- “Hygienic Ceilings: Keeping it Clean Overhead.”: http://www.constructionspecifier.com/hygienic-ceilings-keeping-it-clean-overhead/

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2016/12/ngram.jpg

- Facility Guidelines Institute’s (FGI’s) 2014 Guidelines for Design and Construction of Hospitals and Outpatient Facilities: https://www.fgiguidelines.org/guidelines/2014-hospital-outpatient/

- U.S. Food and Drug Administration (FDA) Food Code : http://www.fda.gov/downloads/Food/GuidanceRegulation/RetailFoodProtection/FoodCode/UCM374510.pdf

- Sanitation Performance Standards Compliance Guide : https://www.fsis.usda.gov/wps/portal/fsis/topics/regulatory-compliance/compliance-guides-index/sanitation-performance-standards/sanitation-compliance-guide

- Maintaining Indoor Environmental Quality (IEQ) during Construction and Renovation: https://www.cdc.gov/niosh/topics/indoorenv/constructionieq.html

- Design Requirements Manual: https://www.orf.od.nih.gov/PoliciesAndGuidelines/BiomedicalandAnimalResearchFacilitiesDesignPoliciesandGuidelines/Documents/2016DesignRequirementsManual/2016_Design_Requirements_Manual_508.pdf

- United States Pharmacopeial (USP) 797, Pharmaceutical Compounding−Sterile Preparations: http://www.usp.org/sites/default/files/usp_pdf/EN/USPNF/usp-gc-797-proposed-revisions-sep-2015.pdf

- Utah’s Administrative Code Rule R392-200, Design, Construction, Operation, Sanitation, and Safety of Schools: http://www.rules.utah.gov/publicat/code/r392/r392-200.htm

- defined by the World Health Organization (WHO): http://www.who.int/biologicals/vaccines/good_manufacturing_practice/en/

- Current Good Manufacturing Practices (21 CFR § 110.20[b][4]): http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?cfrpart=211

- www.ceilume.com/pro: http://www.ceilume.com/pro

- www.chusid.com: http://www.chusid.com

Source URL: https://www.constructionspecifier.com/more-hygienic-ceilings/