Navigating energy code compliance for roofing

Understanding specifications

The R-value refers to the resistance to heat flow in a single material or component. In practice, a high R-value means better insulating values can be achieved. However, R-values do not tell the whole story. U-factors, which measure the actual heat flow through an entire insulated assembly, not just a single material, provide a more detailed assessment of the actual thermal performance.

Mathematically, the U-factor is equal to the inverse of the R-value (U= 1/R).

In most assemblies, the R-value of the various components is not additive or accurately calculated; therefore, it will not predict the performance of the assembly. U-factor measurements, also known as the ‘effective R-value,’ can be more valuable because they measure the flow for multiple components, typical of most building assemblies, each with varying R-values. Focusing on U-factors when assessing roofing assemblies is important because U-values also account for additional components, such as insulation compression and thermal short circuiting that may occur in an actual assembly. U-factors provide a much more accurate prediction of performance and are necessary for sizing heating and air-conditioning systems.

The prescriptive assemblies listed in both IECC and ASHRAE 90.1 take this into account and list both the R-values used in the components and the assembly U-factor. For example, in ASHRAE 90.1-2013, a wall with metal studs 406 mm (16 in.) on center (oc) and filled with R-13 fiberglass insulation, has an assigned U-factor of 0.124 or an effective R-value of 8 (1/.124). The U-factor or lower effective R-value of 8 for the total assembly, when compared with the insulation’s R-value of 13, reflects the heat flow bypassing or thermally short circuiting the fiberglass through the metal studs.

It is important to note any portion of the building envelope can comply with the energy code by either selecting the prescriptive assembly listed in the code or standard, or by selecting any assembly with an equivalent or lower U-factor so long as you can provide a test report for the assembly.

To accurately test insulating values of an assembly, the building industry follows the procedure outlined in ASTM C1363, Standard Test Method for Thermal Performance of Building Materials and Envelope Assemblies by Means of a Hot-box Apparatus. A few manufacturers test their building products and systems to ensure they deliver the energy efficiency promised. Knowing the actual thermal performance of the building envelope helps ensure compliance to energy codes and can be used to more accurately size HVAC equipment. A hot-box apparatus is a state-of-the-art computerized data acquisition system collecting information from multiple sensors used to measure the surface and air temperature, humidity, airflow, and the total energy consumed during the test period. An assembly test specimen representing all the components of the desired building envelope construction is placed in the apparatus. Chambers are installed to both sides of the test specimen. The temperature is dropped to a specified level on one side of the specimen and the energy needed to achieve and maintain a specified different temperature on the opposite side is measured. A single test can take several days to complete. These results measure the actual heat flow through the assembly, expressed as the actual U-factor performance of the assembly in Kw-m2 C (Btu/hr-sf F).

ASHRAE versus IECC

Now that the fundamentals for codes and standards, energy demands, and specifications have been established, it is time to identify the best way to determine whether IECC or ASHRAE standard path is better to follow for a given project.

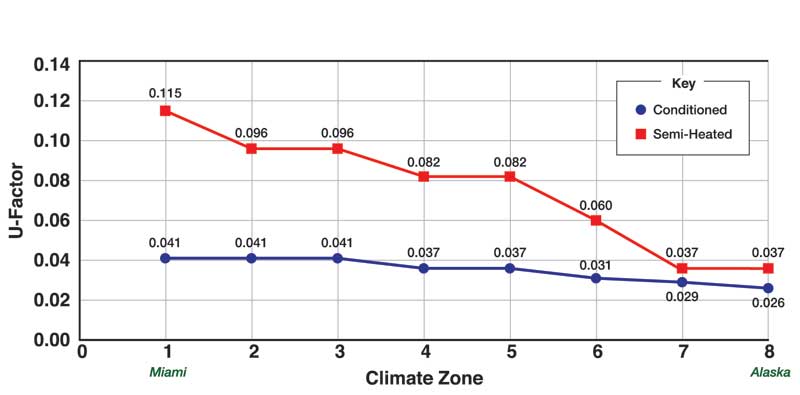

There are positives and negatives for each path and, in many states, one can select either IECC or ASHRAE to be the compliance standard. Up until 2009, the performance requirements for IECC and ASHRAE were nearly identical. Since then, they have remained similar, but now have slight variations and may result in different solutions for the building envelope components. It is often worthwhile to investigate both standards when designing one’s building. Generally, ASHRAE is the only compliance option for semi-heated buildings. When selecting this option, ASHRAE requirements for the entire building must be followed, including other areas such as lighting and mechanical systems.