by Mark Lawinger and Mike Gipson

Two of the biggest restroom plumbing choices are how to provide sensor operation and how to save water with fixtures and flushometers. However, whether products are being specified for a new development or an existing building can have an impact on decisions.

In some cases, a commercial developer is constructing a new facility; in others an owner plans to make extensive renovations to an existing building—either way, plumbing choices come into play. Visitors may judge a company or institution on the restroom’s condition and appeal. Plumbing systems offer a way to both improve the restroom environment and reduce costly water and energy consumption. Therefore, restrooms tend to receive special attention when undergoing new construction or renovations.

Toilets, faucets, soap dispensers, and hand dryers are standard restroom equipment, yet choosing the right mix is anything but standard. There is a wide array of technologies, features, and options to consider, and certain product types will favor—and, in some cases, are specifically designed for—new construction as opposed to renovation projects.

renovations or new construction, choosing toilets and other standard restroom equipment is important. Photo © Dreamstime.com/ Dzmitry Shyshkouski

Although the new construction project manager may have preferences or experiences using certain brands or product types that could impact the decision, the task essentially starts with a clean slate of options. The renovation manager, on the other hand, has a greater interest in selecting products that will work smoothly with what is already in the building—products that fit into the housekeeping regimen, are familiar to maintenance/service personnel, and use parts already on hand. In either case, however, architectural and aesthetic preferences can be incorporated into product decisions.

The major plumbing choices facing specifiers include the power type for sensor-activated products and water consumption. As specifiers consider which products are best for their applications, renovators have the added chore of ensuring selections are the right fit for their facilities, which may have aging plumbing infrastructure and older fixtures.

Power play

Specifiers for new construction and renovation projects are increasingly choosing sensor-activated plumbing products for restrooms. The reasons for selecting touch-free activation include increased hygiene, aesthetics, and convenience, plus reduced vandalism by eliminating handles or faucet metering buttons that can break.

One of the most important sensor choices is the type of power source. The two main power options for sensor plumbing systems are batteries or hardwiring. Energy-saving solar power with battery backup is another choice.

Hardwired sensor flushometer products are more commonly employed in new construction projects because builders can plan ahead of time for electrical hook-up and proper placement. Plus, hardwired products require little to no service once they are installed. These systems run off of transformers, which can each provide power to 10 water closets and/or urinal flushometers. Installers should allow a minimum of 15 VA of current rating per solenoid. As this can vary, consulting the manufacturer on proper transformer sizing based on the number of fittings to be attached is recommended.

Primarily because of the electrical hook-up and need to purchase at least one transformer, hardwired products are more expensive than battery-powered models. Yet, once they are installed, there is no regular maintenance required, which keeps down operating costs.

Also, hardwired flushometers can be concealed entirely behind the wall. These systems, which only reveal a tamper-proof sensor window, are ideal for restrooms prone to vandalism and are favored by architects for their cleaner aesthetic compared to exposed models. Traditionally, hardwired flushometers have not been ideal choices for buildings or areas likely to suffer from power outages, which would render the fittings or fixtures unusable. Some flushometers, however, have mechanical override features with buttons that can be pressed to enable manual operation.

Battery-powered flushometers and faucets are viable options for restrooms where electrical access for hardwiring is difficult to obtain or cost-prohibitive and, as such, they are a common choice for renovations. Battery-powered products, of course, require periodic battery changes.

Solar-powered water closet and urinal flushometers can be a good selection for new construction or renovation. These products use their backup batteries only when insufficient light energy has been stored to activate; this can extend battery life up to double the typical time. These units are easy to install anywhere and operate off any ambient illumination source, including occupancy-controlled lighting.

Renovators can add sensor operation to existing flushometers by installing retrofit flushometer kits. This is a popular option for renovations, because the kits quickly and easily upgrade existing manual flushometers. Facilities can make widespread retrofits with these kits or upgrade flushometers one at a time—whichever makes sense, based on budget and design objectives.

Retrofitting a flushometer is easy. For manual flushometers, side-mounted retrofit kits simply clamp over the handle of a manual flushometer or replace the handle to provide either manual or electronic operation. Top-mount retrofit kits can also upgrade existing manual flushometers by replacing the top cap on the units with sensor-activated modules.

Ways to save water

Many of today’s plumbing fixtures and fittings are designed to use water more efficiently. Partly, the interest in water-efficient plumbing products comes from building owners looking to reduce water and wastewater utility costs. State and local codes are also behind the installation of fixtures and fittings that consume less water.

Although the U.S. Environmental Protection Agency (EPA) requires new water closets to use no more than 6 Lpf (1.6 gpf) and urinals to use a maximum of 3.8 Lpf (1 gpf), some states and local code bodies require even lower water consumption levels. Many areas have now set the water closet flush maximum to 4.8 Lpf (1.28 gpf). Both single-flush and dual-flush toilets that flush at 6.0 Lpf (1.6 gpf) for solids and 4.2 Lpf (1.1 gpf) for liquids for an average of 4.8 Lpf (1.28 gpf), qualify. Specifiers can also choose urinals with flows as low as 0.5 Lpf (0.125 gpf).

For new construction, the decisions are relatively simple—new facilities’ pipes are designed to accommodate the reduced flows of water-efficient plumbing products. Thus, it is completely up to specifiers to choose the water-efficient plumbing products they prefer, including (if local code allows) water-free urinals. Renovators, however, work with aging infrastructure. The infrastructure can impact the performance of plumbing products, as well as the specification of water-efficient products.

Since owners of existing buildings are motivated to save water, they often look to retrofit flushometer kits, which can convert existing flushometers to more water-efficient operation. These kits can upgrade any water closet or urinal fixture rated to perform effectively at a lower-volume flush. Dual-flush flushometers and retrofit kits are just as water efficient as 4.8-Lpf (1.28-gpf) flushometers while providing the added benefit of a periodic, full flush. The 6-Lpf (1.6-gpf) flush can be especially helpful in older buildings that may have difficulty clearing solids with 4.8-Lpf (1.28-gpf) flushes.

Whether starting with a new set of fixtures for a development, or installing retrofit flushometers in existing buildings, it is critical to match the water volume of the flushometers to the fixtures. Urinal and water closet fixtures are rated for specific flush volumes as indicated on the stamped markings on the fixtures. Fixtures either have a single flush volume marked—or a range of volumes, in the case of universal fixtures now available—which indicate the water volume they can adequately handle.

Mismatching flushometers (or diaphragm kits) and fixtures is a common mistake. Older fixtures have features designed to use more water, such as larger trapways and jet holes. Restricting the amount of water supplied to these fixtures from more water-efficient flushometers can result in incomplete flushes or other performance issues. Retrofit products are only meant for upgrading relatively new fixtures that can accommodate the reduced flush volumes.

Due to performance and non-compliance issues, it is advisable in some cases to completely replace older water closet fixtures and flushometers to gain water-efficiency advantages. Additionally, new water-efficient urinal and water closet fixtures have been engineered for greater overall performance, which also makes upgrading worthwhile.

From a retrofit standpoint, a building’s drainline condition is a major concern, especially when using high-efficiency plumbing systems. Older buildings that were constructed at a time when toilets flushed at 13.2 Lpf (3.5 gpf) or higher have drainlines designed to use that much water to effectively move waste.

As buildings conserve water from multiple sources—such as restroom plumbing, dishwashing equipment, and showers—specifiers should be cognizant of piping conditions and how decreased water usage will affect them. Similarly, on the supply side, pipes can become scaly and provide inadequate water pressure and volume over time.

While the fixtures are removed from the wall or floor during the retrofit, this would be an ideal time to conduct any needed drainline maintenance. At this point, personnel may be able to identify other drainline issues to address, such as a sag in the line. To ensure there is enough static or flowing pressure in the lines, facilities may choose to add a booster pump or even replace select pipes.

In short, high-efficiency systems exacerbate any existing drainline problems because they use less water. The margin of error in specifying proper systems and maintaining drainline performance has been reduced greatly, so it is important to do the upfront research and to service the lines as needed.

Renovators only: Fixture dimensions

Another technical consideration for renovations regards fixture dimension. When switching from one fixture brand or model to another, the new wall- or floor-mount fixtures will likely employ the old fixtures’ existing outlet flanges due to the cost and difficulty in moving them.

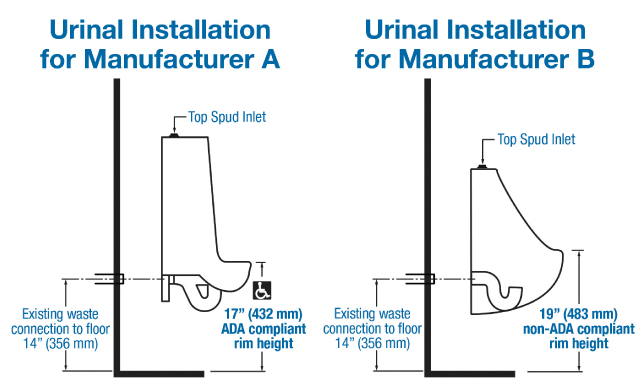

There may be dimensional changes impacting aesthetics and practicality, because fixtures’ outlet-to-rim-dimension varies from manufacturer to manufacturer, as well as from model to model. Installing a new urinal fixture on the same outlet flange of an older one, however, may then mean the rim is higher. This could make a urinal fixture, for instance, non-compliant with Americans with Disabilities Act (ADA), which calls for a urinal rim height maximum of 432 mm (17 in.).

Installing new fixtures in place of older models may also expose old caulk lines that need to be removed. Repainting or retiling parts of the mounting area that were previously hidden may be necessary. One solution is to choose larger-footprint urinal fixtures, designed specifically for retrofit applications, which conceal old holes and markings.

Conclusion

For all types of commercial projects, the options and decisions that are necessary to be made today, as opposed to even 20 years ago, are dramatically different. The plumbing landscape is more complex, yet full of new approaches and technologies to reduce water usage and operating costs, while increasing efficiencies.

Mark Lawinger is the fixture product line manager for Sloan Valve Company, a manufacturer of water- and energy-efficient commercial restroom plumbing procuts. He has a background in business development, marketing, and product management for commercial and industrial systems. Lawinger can be reached by e-mail at mark.lawinger@sloanvalve.com.

Mike Gipson is the flushometer product line manager at Sloan Valve Company. He has held various brand management roles at commercial and consumer product companies and can be reached at mike.gipson@sloanvalve.com.

To read the sidebar, click here.