The Plastics Pipe Institute (PPI) has launched an innovative Model Specification, revolutionizing the selection and installation of polypropylene plastic piping in plumbing and mechanical projects.

The document, PPI MS-8 Model Specification for Polypropylene (PP-R & PP-RCT) Pressure Pipe Systems for Plumbing & Mechanical Applications, crafted by PPI’s building and construction division (BCD), addresses a wide spectrum of applications, including hot and cold water plumbing, hydronic heating, and district energy systems.

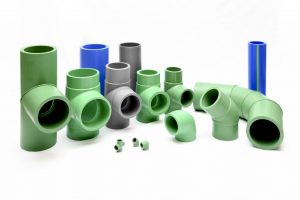

Polypropylene pressure pipes boast high temperature and pressure capabilities, making them ideal for demanding environments such as commercial buildings, data centers, and healthcare facilities. Lance MacNevin, director of engineering for PPI’s BCD, emphasizes the versatility of polypropylene, available in two types—PP-R and PP-RCT.

PPI MS-8 serves as an updated, comprehensive guide for engineers and specifiers, offering language that can be seamlessly integrated into design documents. It covers aspects such as pipe and fitting specifications, installation procedures, pressure testing, and commissioning. Notably, polypropylene systems leverage heat fusion for leak-free connections without open flames.

MacNevin highlighted the pitfalls of using outdated language, pointing out that the product standards for PP piping have evolved over the years.

The new model specification aligns with the latest standards and codes from organizations such as ASTM, CSA Group, National Sanitation Foundation (NSF), International Association of Plumbing and Mechanical Officials (IAPMO), and International Code Council (ICC). It includes tailored requirements for potable water and chilled water applications, flame and smoke ratings, thermal barriers, and more.

Additional information and data about polypropylene and other piping materials is available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction.