The test and the data

As shown in Figure 2 (page 28), the NFPA 285 test method is an assembly fire test that evaluates the fire propagation characteristics of exterior wall assemblies that contain combustible components such as, but not necessarily limited to, combustible claddings, insulation and many air and water-resistive barriers. The multi-story test assembly measures:

- flame propagation over exterior wall surface;

- vertical flame propagation within the wall assembly or its components;

- lateral flame propagation within the wall assembly or its components; and

- vertical flame propagation from one floor to the next.

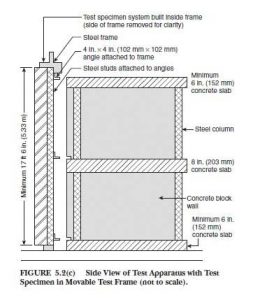

NFPA 285 test method evaluates vertical and lateral flame propagation characteristics of full-scale exterior wall assembly designs. The fire exposure simulates a fire scenario where a post-flashover fire has breached the exterior window of the room of origin, exposing the exterior of the wall to a flame assault and heat plume. Test specimens are full-scale, minimum 5.3 m (17.5 ft) by minimum 4 m (13.3 ft), and fully configured wall assemblies, containing all assembly layers (i.e. exterior wall covering, water-resistive barrier, air barrier, vapor barrier/retarder, and insulation), accessories (e.g. sealants, brackets, shims, etc.), and a base wall (typically a light-gauge metal frame curtain wall).

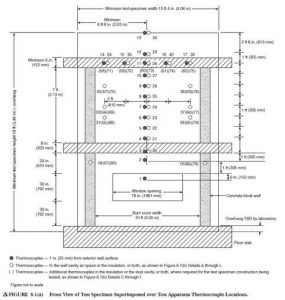

Each test wall assembly is highly instrumented with each assembly layer—including air gaps—containing multiple thermocouples (TCs). Number of TCs, TC location, and any applicable acceptance criteria are specified by the NFPA 285 test method and determined by the materials of construction and the configuration of the wall assembly. Acceptance criteria determining the pass/fail result is a combination of temperature limitations, temperature-rise limitations, and visual observations of flaming at specified locations in the test specimen and the second-story room of the test apparatus. Information required for test reports includes time versus temperature data for all TCs, visual observations, photographs of the assembly (pre-test exterior, pre-test interior, post-test exterior, post-test interior, and wall cavity insulation post-test), damage sketch(es), other burner-related and calibration-related information, and detailed drawings for the assembly and window opening area (Figure 3).

The data collected during an NFPA 285 test records the ‘real time’ dynamic behavior of each individual assembly layer. When combined, the data from all assembly layers describes how heat and fire moved throughout the assembly in all three dimensions—vertically, horizontally, and through. It is this quality of NFPA 285 test data that makes it possible for qualified individuals, using experience and sound principles of fire science and fire engineering, to evaluate performance effects of certain modifications to tested assemblies and to confirm, with confidence, the alternative assembly will continue to comply with the acceptance criteria of NFPA 285(Figure 4).

After a testing period of 30 minutes, a successful test will show no flame propagation to the second story room and none of the thermocouple locations having acceptance criteria may exceed the prescribed limit (e.g. 260, 398.9, 537.7 C [500, 750, 1000 F] or temperature rise less than 260 or 398.9 C [500 or 750 F]). Flame spread cannot exceed 3 m (10 ft) above the top of the window, nor more than 1.5 m (5 ft) laterally from the centerline of the window.

Engineering judgments

Engineering analyses extending full-scale NFPA 285 test results are a determination of equivalence, whether a modified assembly will perform at least equivalently to the tested assembly in terms of the acceptance criteria. As discussed above, NFPA 285 test data tells a detailed story of how an assembly performed throughout the test. This detailed data, when reviewed by qualified individuals, provides valuable information and insight into each assembly layer’s behavior as well as its influence on, and reaction to, the behavior of adjacent assembly layers. Ongoing fire testing, consulting and certification continues to increase experience, understanding of comparative performance, and knowledge of performance trends for products and assemblies subjected to the NFPA 285 test. Put simply: every test result provides knowledge, educating every test that follows.

Under the IBC, there are three compliance pathways for an exterior wall requiring NFPA 285 testing. First, an individual exterior wall assembly is tested and meets the acceptance criteria. Second, an exterior wall assembly design is tested and listed or certified by an approved agency for compliance with NFPA 285. Third, an engineering analysis or judgment based on the test data for a similar assembly showing compliance with the acceptance criteria.

Engineering judgments are reports issued by credible individuals or organizations to provide an assessment of component substitutions or installation/configuration deviations compared against an assembly tested to NFPA 285. They determine whether the variation, change, or substitution still results in a wall assembly that exhibits similar fire performance, meeting the acceptance criteria of the NFPA 285 test or tests that form the baseline.

A credible engineering judgment should be issued by a qualified organization or individual, clearly describe the conditions with drawings if necessary, stipulate the engineering judgment is not a tested or listed assembly, reference the base tested assemblies upon which the judgment is issued, and identify deviation from the tested assembly along with the supporting argument and data. Acceptance of an engineering judgment for building code compliance affirms the proposed design and use will result in a level of safety and performance that meets the intent of the applicable codes and standards. Only the authority having jurisdiction (AHJ) may accept the engineering judgment for building code compliance.

Listings, certifications and code reports

Many manufacturers develop and maintain third-party certifications for assemblies tested in accordance with NFPA 285. These certifications are provided by duly accredited agencies and take the form of design listings and code evaluation/research reports that recognize specific assembly configurations and components. Designers and AHJs rely on third-party certifications to be accurate, current, and representative of the products, assemblies, and performance recognized in the listings and code reports.

Third-party certification has three basic phases: sampling and testing; assessment and certification; and ongoing maintenance. The first two phases are straightforward—test representative samples of products and assemblies to collect performance data which is then evaluated for compliance with the applicable requirements. If found compliant, certification (i.e. recognition) is granted.

Design listings for assemblies complying with NFPA 285 are available directly from certification agencies through online product directories. Code evaluation/research reports are also available directly from certification agencies through online directories such as those provided by the International Code Council-Evaluation Service (ICC-ES), Intertek, and Underwriter’s Laboratories (UL).

After certification is granted, ongoing certification maintenance includes regular verification the manufactured product is consistent with what was tested. This is accomplished through verification testing or manufacturing surveillance inspections. In addition to monitoring the products, ongoing certification maintenance requires monitoring of test methods and performance standards for changes that may impact associated listings. When test methods or standards are updated, a certification agency must evaluate technical changes to determine if existing listings are impacted in terms of recognized performance or, in the case of assemblies, the recognized configuration. This can range from no impact up to existing testing no longer complying with the standard. When technical changes effect existing listings, it is usually possible to revise the listing. Revisions may range from limiting the scope of recognition (e.g. not recognizing NFPA 285, 2019 edition or the 2021 IBC) to listing cancellation. These evaluations are performed by the certification agency within their respective competencies and scopes of accreditation.

The 2019 edition of NFPA 285 contains several substantive technical changes regarding the test specimen construction. These changes will require certification agencies to review test data that was conducted in accordance with earlier editions of NFPA 285 and perform an engineering judgement regarding compliance with the 2019 edition of the standard. Depending on the certification agency, such engineering judgments may rest upon evaluations of existing data, review of engineering judgments submitted by the listing holder, or a combination of both.