by Kevin Ramus

As one of the world’s most versatile building materials, with a wide range of aesthetic options and outstanding energy characteristics, glass provides numerous opportunities to enhance buildings’ visual appeal and performance. As glass panels and insulating glass units (IGUs) become larger and glass occupies more real estate on curtain walls, storefronts, and interior building components, ensuring color uniformity and consistency across the façade becomes both more challenging and more critical.

It is important for architects to be aware of and attain color uniformity with glass. This can be facilitated by becoming familiar with the globally recognized L* a* b* color system developed by the International Commission on Illumination (CIE). It is also helpful to address related building glazing-color specifications and proven glazing-sample viewing techniques for more effective color evaluation.

Measuring color in glass

Color uniformity of glass in an architectural application can be defined as variation in appearance of the color or shade within one glazed unit, or between multiple glazed units of the same type installed in the same plane and elevation of a building. However, as discussed later in this article, the appearance of visually perceived color differences within or between installed glazing units does not necessarily mean color uniformity requirements have not been met. This is where measuring the actual color of glazing units comes into play—a process that begins with the measurements taken during the glazing manufacturing process. For the proper context, however, one should first define what ‘color’ is before addressing the topic of color measurement.

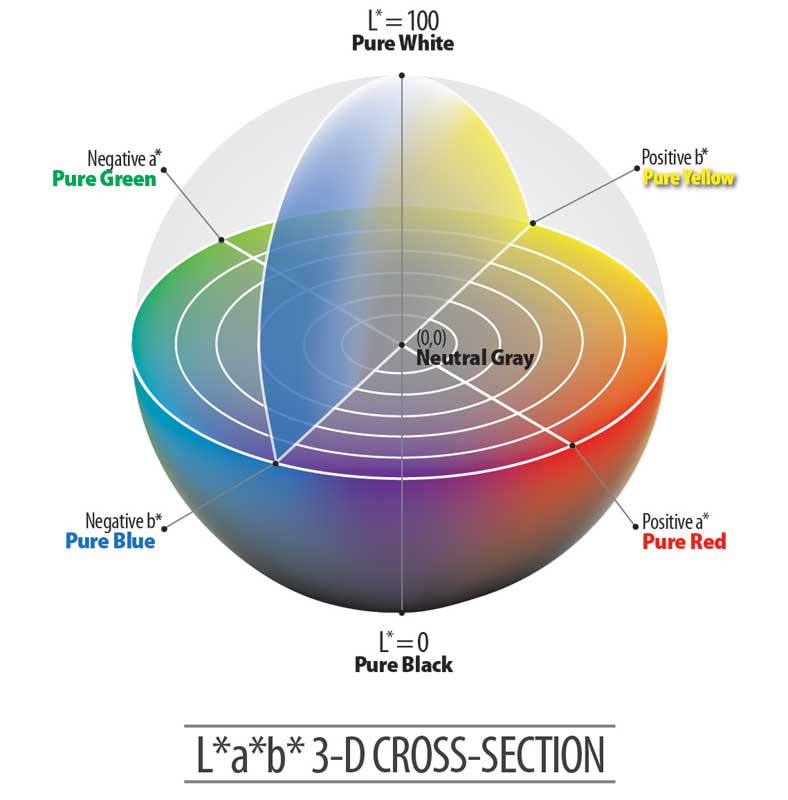

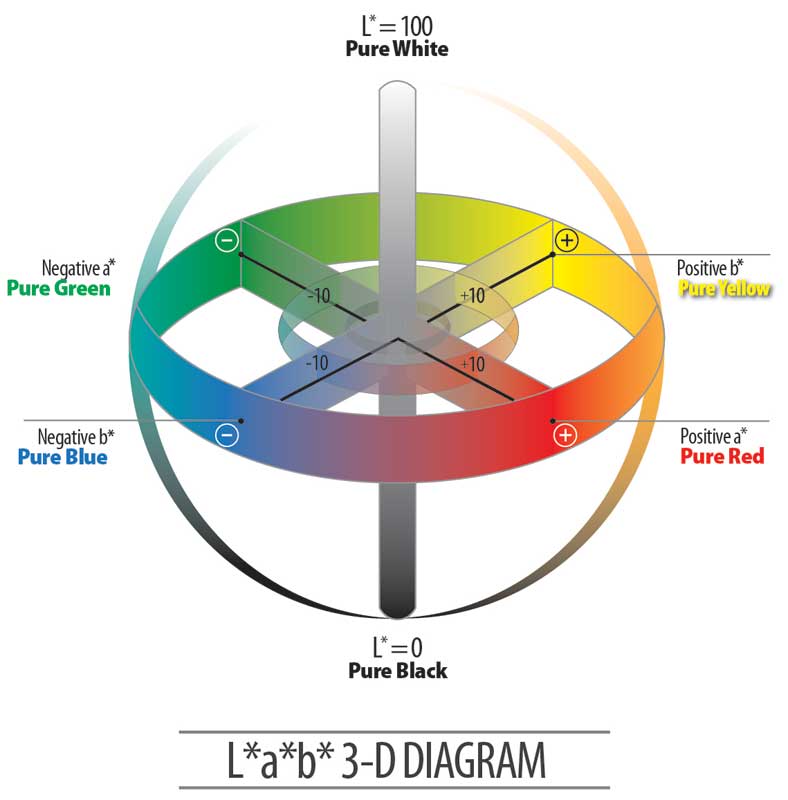

For the purposes of industry standardization, color is typically defined according to a mathematical model developed by CIE. This globally recognized ‘color’ system numerically defines the color of glass (or any object, for that matter) with three vectors in a three-dimensional color space:

- L* (luminance: lightness to darkness);

- a* (green to red); and

- b* (blue to yellow).

As seen in Figures 1 and 2, the L* values range from darkest to lightest (0 to 100) in this model. Positive a* values are more red, while negative a* values are more green. Positive b* values are more yellow, while negative b* values are more blue. Most glass and coated glass products—with the exception of painted spandrels—are fairly neutral in color and have L* values ranging from 20 to 97 and a* and b* values ranging from –10 to +10.

For example, a commercially available tinted glass that appears light blue has a transmitted color of:

L*= 80.0

a*= –4.8

b*= –10.0

By comparison, clear glass that appears slightly green has a measurement of:

L*= 95.4

a*= –1.8

b*= 0.1

However, when a neutral-reflective low-emissivity (low-e) coating is applied to the second surface of clear glass in an IGU, the color changes to a new measurement of:

L*= 74.1

a*= –4.7

b*= –3.2

In this case, when looking through the glass in transmission, it takes on a somewhat darker bluish-green appearance.

When viewing in transmission is that meant to always view the glass from the interior pane outward?

No, transmission color should be the same in both ways