Color differences and tolerance

Based on the unique color target for each coated glass product, ASTM C1376 requirements for color uniformity can be applied. For instance, if there are concerns color uniformity requirements have not been met on the jobsite, it is appropriate to compare the color data measured with a spectrophotometer for the glazing in question to the data of glazing with acceptable appearance. This color measurement can be done pre- or post-installation on the glazing exterior by anyone trained in the use of a spectrophotometer made for such field measurement applications.

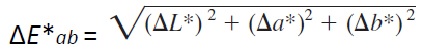

The color difference equation can then be used to calculate the differences between two color measurements for comparative purposes per ASTM D2244. This equation is referred to as DE*ab and calculated using the following formula:

This formula can be used to compare the reflected colors of two low-e-coated glass samples.

The first sample’s reflected color is:

L* = 33.0

a* = 4.0

b* = 2.0

The second sample’s reflected color is:

L* = 33.5

a* = 5.0

b* = 4.0

The color difference between them is calculated as follows:

ΔE*ab = SQRT((33.5-33.0)2+(5.0-4.0)2+(4.0-2.0)2) = 2.3

The calculation between a color target and a color measurement taken on a piece of glass can be done in a similar fashion. ASTM C1376 describes how the color target can be obtained and used to determine color uniformity. This allows glass colors to be compared objectively without the effect of ambient light, viewing angle, or an individual viewer’s subjective perception.

Color uniformity considerations in glazing design

The early stages of glazing design and material selection are the optimal time to take stock of glazing color uniformity. The following factors need to be considered.

- Viewing glass samples against a white background emphasizes transmitted color, while a very dark background emphasizes reflected color. As mentioned, glass installed on buildings includes components of both color types blended together.

- Glass samples should be evaluated in natural daylight, because artificial light may emit wavelengths of light that can skew the visual perception of glass color.

- Perceived glass color can be influenced by sample size. The color of a 305 x 305-mm (12 x 12-in.) sample may not appear the same as a 1 x 3-m (4 x 10-ft) glazed unit of the identical glass. This is known as field-size metameric failure, which occurs because the relative proportions of the three cone types in the human eye (i.e. red, green, and blue) vary from the center of the visual field to the periphery.

- Use of tinted glass on the outer lite—especially darker tints—masks much, if not all, of the color differences in the low-e coating behind it. When low-e coatings are placed in front of darker tints, the opposite effect occurs and the coating color differences are enhanced. Care must be taken when using dark tints to ensure consistent tin/air-side orientation in IGU or laminate assemblies.

- In some cases, low-e coatings developed and optimized for the second surface of an IGU can be placed on the third surface, but might have more color variation. For solar control applications, a dark-tinted outer lite can mask color variations when third-surface coatings are desired by design. An IGU with designated second-surface coating that is manufactured or installed backwards will have a noticeable color difference, because the coating as installed is now on the third surface. The energy performance of such a ‘backwards-installed’ glazing will also be affected.

- Coatings on multiple surfaces will have combined color effects. For example, the colors of a low-e coating on the second and fourth surfaces are additive. Another example is low-e coatings on multiple surfaces of triple IGUs.

- Surrounding conditions—such as overhangs, shadows, and reflections from trees or other buildings—affect perceived color uniformity.

- Building orientation, different elevations, and viewing conditions can affect color perception. How direct and indirect sunlight shines on the glazing is determined, in part, by whether the building faces north-south or east-west. For example, north elevations tend to receive less direct sunlight and, therefore, more shadows; this can affect perceived color.

- Glazing with exposed edges appears different to the eye because of edge lighting effects. With an exposed glass edge, light can enter the body of the glass through the edge and illuminate it.

- Interior shading devices and shadow boxes can affect perceived color.

- Glazing constructed of different glass types—such as spandrels, laminated glass, and glass with dot/line patterns—can affect how the color is perceived.

- Provided heat strengthening or tempering is done properly, the resultant color is not affected.

When viewing in transmission is that meant to always view the glass from the interior pane outward?

No, transmission color should be the same in both ways