The nuances of vision glazing color

by Katie Daniel | November 2, 2017 12:38 pm

[1]

[1]by Kevin Ramus

As one of the world’s most versatile building materials, with a wide range of aesthetic options and outstanding energy characteristics, glass provides numerous opportunities to enhance buildings’ visual appeal and performance. As glass panels and insulating glass units (IGUs) become larger and glass occupies more real estate on curtain walls, storefronts, and interior building components, ensuring color uniformity and consistency across the façade becomes both more challenging and more critical.

It is important for architects to be aware of and attain color uniformity with glass. This can be facilitated by becoming familiar with the globally recognized L* a* b* color system developed by the International Commission on Illumination (CIE). It is also helpful to address related building glazing-color specifications and proven glazing-sample viewing techniques for more effective color evaluation.

Measuring color in glass

Color uniformity of glass in an architectural application can be defined as variation in appearance of the color or shade within one glazed unit, or between multiple glazed units of the same type installed in the same plane and elevation of a building. However, as discussed later in this article, the appearance of visually perceived color differences within or between installed glazing units does not necessarily mean color uniformity requirements have not been met. This is where measuring the actual color of glazing units comes into play—a process that begins with the measurements taken during the glazing manufacturing process. For the proper context, however, one should first define what ‘color’ is before addressing the topic of color measurement.

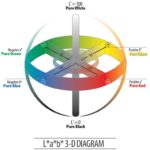

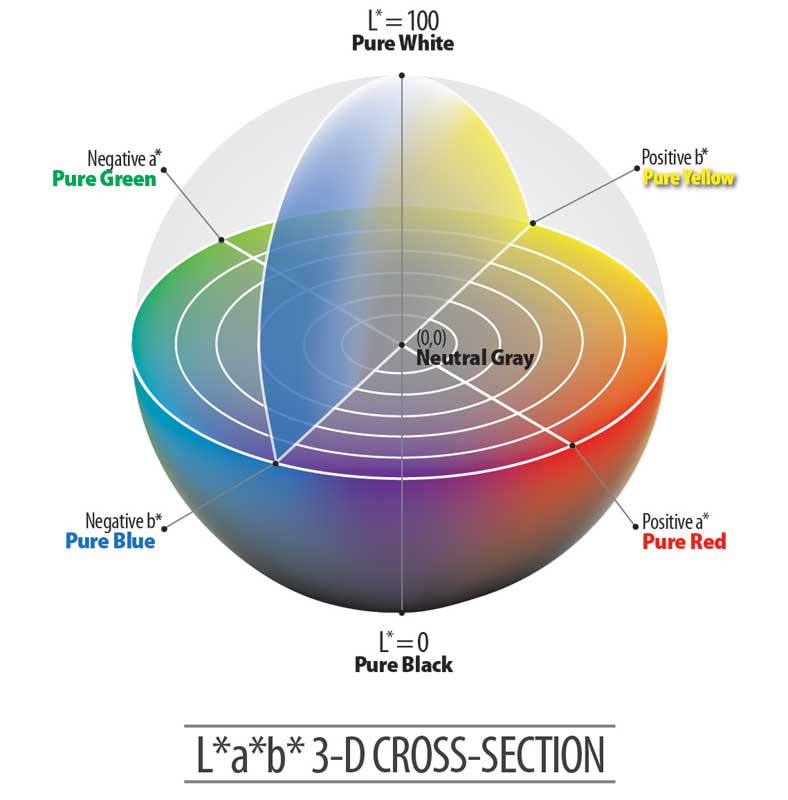

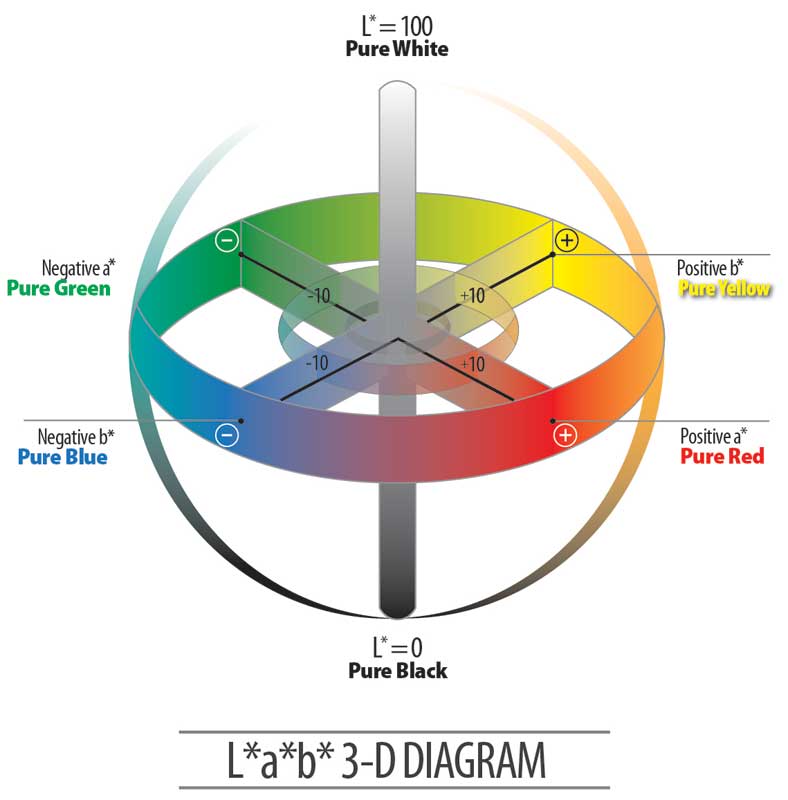

For the purposes of industry standardization, color is typically defined according to a mathematical model developed by CIE. This globally recognized ‘color’ system numerically defines the color of glass (or any object, for that matter) with three vectors in a three-dimensional color space:

- L* (luminance: lightness to darkness);

- a* (green to red); and

- b* (blue to yellow).

As seen in Figures 1 and 2, the L* values range from darkest to lightest (0 to 100) in this model. Positive a* values are more red, while negative a* values are more green. Positive b* values are more yellow, while negative b* values are more blue. Most glass and coated glass products—with the exception of painted spandrels—are fairly neutral in color and have L* values ranging from 20 to 97 and a* and b* values ranging from –10 to +10.

For example, a commercially available tinted glass that appears light blue has a transmitted color of:

L*= 80.0

a*= –4.8

b*= –10.0

By comparison, clear glass that appears slightly green has a measurement of:

L*= 95.4

a*= –1.8

b*= 0.1

However, when a neutral-reflective low-emissivity (low-e) coating is applied to the second surface of clear glass in an IGU, the color changes to a new measurement of:

L*= 74.1

a*= –4.7

b*= –3.2

In this case, when looking through the glass in transmission, it takes on a somewhat darker bluish-green appearance.

[4]

[4]Color measurement

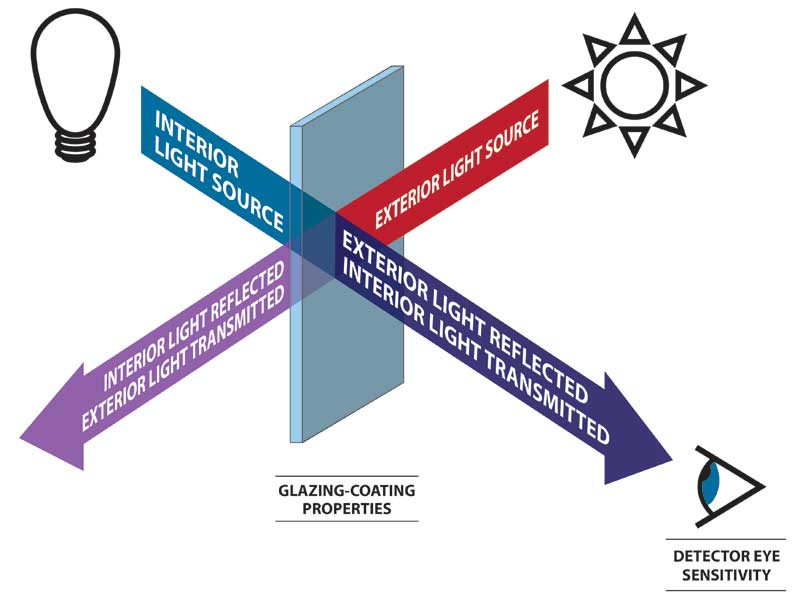

Glass is a unique material in that it has a transmitted color (i.e. what is seen looking through the glass) and a reflected color (i.e. what is seen looking at the glass, usually with some viewing angle). Therefore, what the eye sees is a blending of both the transmitted and reflected colors of the glazing.

A spectrophotometer—a sophisticated instrument made up of a known light source, a sample holder or port, an integrating sphere to collect light, and a known light detector—is used to measure an object’s color. Most types of spectrophotometers can measure both transmitted and reflected color and have built-in software to calculate the measured color of an object and provide numerical L*a*b* data, which can then be compared to the color of other objects.

Glazing color uniformity is formally defined or referenced in several industry standards published by ASTM International. ASTM C1376, Standard Specification for Pyrolytic and Vacuum Deposition Coatings on Flat Glass, and ASTM D2244, Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates, are the building glazing industry standards. They utilize L*a*b* color measurements with the spectrophotometer oriented perpendicular to the glass surface.

ASTM C1376 sets the limit of the exterior color uniformity range for pyrolytic- and vacuum deposition-coated flat glass both within a glazed unit and from one glazed unit to the next. It is important to note visually observable differences are possible within this specified range. ASTM C1376 also notes glass may have a perceived color difference when viewed from different angles. This is a common phenomenon and does not necessarily indicate a reason to reject the product.

How low-e coatings affect light and color

Low-e glass is often specified for IGUs and curtain wall assemblies because of its ability to transmit light and diminish heat gain, thereby increasing the energy efficiency of buildings. This glass type is formulated with multiple ultra-thin layers of materials—mainly silver and other metal oxides—on the surface of clear and tinted glass substrates of varying thicknesses.

Most often, this coating is deposited on the surface by magnetron sputter vacuum deposition (MSVD)—a high-tech process in which multiple nanolayers of heat- and light-controlling materials are applied to the glass surface one atom at a time. This activity takes place in a chamber vacuumized to levels equivalent to those of outer space. Accurate gas flow controls and precise monitoring are critical to successfully depositing MSVD coatings—whose thicknesses are typically measured in angstroms (Å)—on the surface of the glass substrate. The optimal coating stack is only about 0.0002 times as thick as the glass lite onto which it is coated.

Chemical vapor deposition (CVD), an alternative, cost-effective coating process, is used more for adding tinted or reflective coatings, which can also have some low-e properties, to a glass substrate. The CVD process is typically conducted at atmospheric pressure (i.e. no special high-vacuum chamber is required) and frequently with heat, depositing coatings onto hot substrate glass. When materials are fed into the CVD chamber or sprayed onto the hot glass, a chemical reaction occurs and deposits form on the glass surface while byproducts are taken away in the exhaust. The types of materials better suited to the CVD process are somewhat limited, and the coating layer thickness controls are not as good as they are with the MSVD process. Therefore, the types of resultant coatings are also somewhat limited to tinted and/or reflective, and the low-e properties are not as good as with silver-based MSVD coatings.

[5]

[5]Even at these low levels of thickness, low-e coatings affect the light that passes through, is absorbed by, or reflects off of them. The interaction between light, the coated glass, and the eye of the person looking at the glass relates directly to color uniformity, as seen in Figure 3.

Low-e coatings can also increase the amount of reflection, which adds to the perceived color, especially when viewed from the building exterior. During certain conditions, such as a cloudy day, the reflected color appearance may dominate, particularly when viewed against the dark background of an unfinished building interior. Ambient conditions also change with the time of day as well as the angle of the sun, depending on the viewing perspective and whether one is seeing direct or indirect sunlight reflecting in the glazing.

However, once construction of the building is complete, the appearance of the glazing will change because the background and light coming from behind the glass emphasize transmitted color and mute reflected color. Consequently, color differences visually perceived before construction is completed will often become more muted once the building is finished.

[6]

[6]Color differences and tolerance

Based on the unique color target for each coated glass product, ASTM C1376 requirements for color uniformity can be applied. For instance, if there are concerns color uniformity requirements have not been met on the jobsite, it is appropriate to compare the color data measured with a spectrophotometer for the glazing in question to the data of glazing with acceptable appearance. This color measurement can be done pre- or post-installation on the glazing exterior by anyone trained in the use of a spectrophotometer made for such field measurement applications.

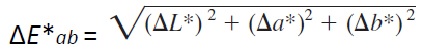

The color difference equation can then be used to calculate the differences between two color measurements for comparative purposes per ASTM D2244. This equation is referred to as DE*ab and calculated using the following formula:

[7]

[7]

This formula can be used to compare the reflected colors of two low-e-coated glass samples.

The first sample’s reflected color is:

L* = 33.0

a* = 4.0

b* = 2.0

The second sample’s reflected color is:

L* = 33.5

a* = 5.0

b* = 4.0

The color difference between them is calculated as follows:

ΔE*ab = SQRT((33.5-33.0)2+(5.0-4.0)2+(4.0-2.0)2) = 2.3

The calculation between a color target and a color measurement taken on a piece of glass can be done in a similar fashion. ASTM C1376 describes how the color target can be obtained and used to determine color uniformity. This allows glass colors to be compared objectively without the effect of ambient light, viewing angle, or an individual viewer’s subjective perception.

Color uniformity considerations in glazing design

The early stages of glazing design and material selection are the optimal time to take stock of glazing color uniformity. The following factors need to be considered.

- Viewing glass samples against a white background emphasizes transmitted color, while a very dark background emphasizes reflected color. As mentioned, glass installed on buildings includes components of both color types blended together.

- Glass samples should be evaluated in natural daylight, because artificial light may emit wavelengths of light that can skew the visual perception of glass color.

- Perceived glass color can be influenced by sample size. The color of a 305 x 305-mm (12 x 12-in.) sample may not appear the same as a 1 x 3-m (4 x 10-ft) glazed unit of the identical glass. This is known as field-size metameric failure, which occurs because the relative proportions of the three cone types in the human eye (i.e. red, green, and blue) vary from the center of the visual field to the periphery.

- Use of tinted glass on the outer lite—especially darker tints—masks much, if not all, of the color differences in the low-e coating behind it. When low-e coatings are placed in front of darker tints, the opposite effect occurs and the coating color differences are enhanced. Care must be taken when using dark tints to ensure consistent tin/air-side orientation in IGU or laminate assemblies.

- In some cases, low-e coatings developed and optimized for the second surface of an IGU can be placed on the third surface, but might have more color variation. For solar control applications, a dark-tinted outer lite can mask color variations when third-surface coatings are desired by design. An IGU with designated second-surface coating that is manufactured or installed backwards will have a noticeable color difference, because the coating as installed is now on the third surface. The energy performance of such a ‘backwards-installed’ glazing will also be affected.

- Coatings on multiple surfaces will have combined color effects. For example, the colors of a low-e coating on the second and fourth surfaces are additive. Another example is low-e coatings on multiple surfaces of triple IGUs.

- Surrounding conditions—such as overhangs, shadows, and reflections from trees or other buildings—affect perceived color uniformity.

- Building orientation, different elevations, and viewing conditions can affect color perception. How direct and indirect sunlight shines on the glazing is determined, in part, by whether the building faces north-south or east-west. For example, north elevations tend to receive less direct sunlight and, therefore, more shadows; this can affect perceived color.

- Glazing with exposed edges appears different to the eye because of edge lighting effects. With an exposed glass edge, light can enter the body of the glass through the edge and illuminate it.

- Interior shading devices and shadow boxes can affect perceived color.

- Glazing constructed of different glass types—such as spandrels, laminated glass, and glass with dot/line patterns—can affect how the color is perceived.

- Provided heat strengthening or tempering is done properly, the resultant color is not affected.

[8]

[8]The importance of using full-size mockups

As a blend of transmitted and reflected color, glass color is uniquely influenced by many factors, including light source, the properties of the coated glass, interior and exterior lighting conditions, viewing angle, glass size, and differences in human observers.

Thus, when evaluating glazing color early in the project, it is recommended to use full-size glass mockups with multiple units of the same glazing type, ensuring all variables replicate those of the finished building and surrounding environment. It is best to review the mockups under various viewing conditions (e.g. exterior/interior, straight on/at angles, cloudy/sunny, blinds/no blinds, and with/without shading devices and reflections of adjacent structures/trees) with all project stakeholders.

It is advisable that actual color data be provided on the glazing used for the mockup. The mockup should be retained throughout the project as a reference of what was reviewed and approved for visual appearance. However, due to angular color considerations, a mockup viewed at ground level with a limited number of glazing units might still appear somewhat different than the completed glazing curtain wall 30 stories above the ground. It is up to the glazing specifier whether or not the color data for the mockup samples is officially requested as part of the submittal.

When evaluating glass samples, they should be viewed in natural daylight (not direct sunlight) rather than in an office environment due to the effects of artificial light previously discussed. It is also important to note the foreground and background when viewing samples, since this will influence what the eye perceives. Viewing the samples in the as-installed position (typically vertical), straight on, and at various angles provides a sense of the variation in appearance due to viewing conditions.

To obtain a true visual comparison when viewing multiple samples simultaneously, it is important to ensure the viewing angle, lighting, foreground and background, and other conditions are identical to the greatest degree possible.

Conclusion

Glazing color uniformity is crucial to maintaining the desired look and architectural integrity of contemporary buildings. Although different observers will form their own unique perceptions of glass colors based on a variety of factors, it is critical for building owners, architects, contractors, glazing installers, glazing fabricators, and manufacturers to become familiar with the nuances of vision glazing color by understanding the industry-standard L*a*b* color measurement system. It is equally important to use full-size mockups to properly evaluate glass color and to consider the environmental and viewing conditions, building orientation, and type of glazing being reviewed.

Kevin Ramus has more than 30 years of experience in the glass industry, primarily with automotive and architectural glass. Since 1989, he has been with Vitro Architectural Glass (formerly PPG Flat Glass) in numerous capacities, including manufacturing, sales, marketing, quality, and—most recently—technical support and service. Ramus holds a bachelor’s degree in ceramic engineering from Iowa State University. He can be reached via e-mail at kramus@vitro.com[9].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/JW-Marriott-Houston.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/3-d-cross-section_091417.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/3-d-diagram091417.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/Nemours-duPont-Childrens-Hospital.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/light-glass-sys-interaction091317.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/Wyndham-Desert-Blue.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/equation.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/11/WESTMED-Medical-Center.jpg

- kramus@vitro.com: mailto:kramus@vitro.com

Source URL: https://www.constructionspecifier.com/nuances-vision-glazing-color/

[2]

[2] [3]

[3]