By Rich Rinka

Fueled by traffic, construction, airplanes, and children playing in the schoolyard, noise pollution is an ongoing challenge. Many buildings, particularly those located near airports, freeways, and construction zones, struggle with undesirable acoustics.

As more and more building owners request better acoustics in new and existing buildings, architects and contractors are seeking guidance on acoustical glass design and a better understanding of acoustical testing and ratings for fenestration products and systems.

One area where the impact of poor acoustics is most prominent is in schools and classrooms. The World Health Organization (WHO)1 states effective classroom learning can only occur in environments where background noise does not exceed 35 decibels (dB). Not only has poor acoustics been directly linked to a child’s ability to learn, but too much noise impacts behaviour and causes stress and fatigue for both students and teachers.

Since the late 1990s, many cities and provinces have acknowledged this issue and created programs that recognize the impact on of acoustics on quality of life. Major airports across the country have plans and have made improvements in acoustical controls.

To assist with the design, specification, and installation of these products, a number of key documents are available. These include several from the Fenestration and Glazing Industry Alliance (FGIA), specifically IGMA TM-6000, Technical Manual for Acoustical Glass Design;2 AAMA 1801, Voluntary Specification for the Acoustical Rating or Exterior Windows, Doors, Skylights and Glazed Wall Sections;3 and AAMA TIR-A1, Sound Control for Fenestration Products.4

Defining sound control

These documents focus on defining and explaining terms and technical issues surrounding the sound transmission loss (STL) of windows and glazing.

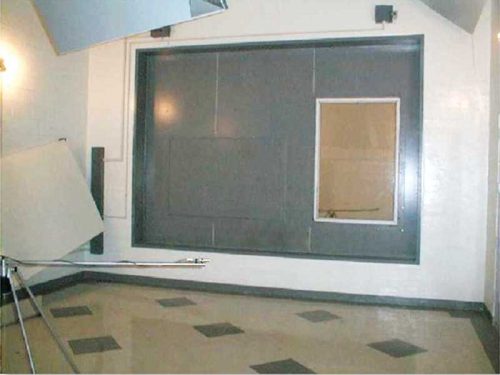

The introduction of IGMA TM-6000 further presents the challenge of creating acoustical control where glass is desired, particularly in airports, hotels, control rooms, schools, and offices where both visibility and sound control is needed.

Since monolithic glass is unable to screen high frequency noises, it is relatively ineffective for these applications. Double-glazed insulated glass can be a better approach for screening these higher frequencies, as airspace combined with different glass thickness may improve acoustical performance. However, the span of the airspace between the two glass spans, which is required for sound control, presents practical limitations. One solution is setting the double glazing in separate frames and lining the space with a sound-absorbent material. Setting glass at different angles would be an architectural element. It may be possible that different angles of attack of the sound would create different acoustical properties, but unless designed into the structure, could create appearance issues. Without testing individual applications and designs, this should not be a suggested resolution.

Sound control

Sound control is defined as acoustical privacy or the elimination of interfering or distracting sound. While there is usually some level of background noise coming from the outside into a space, as long as it stays below the threshold of ambient sound, perhaps with the assistance of an acoustic barrier, it is not distracting.

Sound is a complex combination of frequencies, therefore, acoustic solutions must be designed to mitigate the sound level across key frequencies. For example, an acoustical barrier at an airport terminal must reduce both the high and low frequencies from the planes, whereas in an office, it is the middle frequencies of speech and keyboards that are of concern, and in a motel, the low-frequency rumble of vehicle traffic must be controlled.

The amplitude or loudness level of sound is called the sound pressure level and it is measured in decibels (dB). The louder the sound, the higher the dB and vice versa; dBs are measured on a logarithmic scale. Due to a human’s perception of continuous sound, an increase or decrease in sound pressure level by 3 dB or less is barely perceptible. However, the perception does occur with a 5 dB change. A change of 10 dB is heard as doubling the perceived loudness.

IGMA TM-6000 and AAMA TIR-A1-15 provide an explanation of key acoustic terminology and how sound travels.

Decibel scale

Another important term is a decibel scale, dBA. The human ear is most sensitive to sound in a specific frequency range, A-weighted sound pressure levels filter the acoustic signals within this audible frequency range, thereby producing this dBA value.

As a point of reference, an aircraft taking off at 30 m (100 ft) has an A-weighted sound pressure level/dBA of 120, a car horn 3 m (10 ft) away is about 95 dBA, and a normal conversational speech has a dBA value of 60.

The frequency of sound is called pitch. While most sounds are complex mixtures of different frequencies, it is possible to display the relative positioning of typical sounds and their peak frequencies.

Noise criteria (NC) curves are the approximate equal perceived loudness for sound over the audible frequency range. The NC range quantifies this value ranging from very quiet NC20/30 dBA to extremely noisy NC70/75 dBA, and is also referenced in facility design.

Understanding sound transmission

As sound travels through a room, if it runs into a partition, that partition will both vibrate and cause the air on the other side to vibrate as well. This is called sound transmission. The extent to which the panels promote transmission is a function of its mass and stiffness. The more dense/less porous the panel is, the more resistant it is to sound transmission, whereas the softer the panel, or the lower its stiffness, the less it is able to resist sound transmission. In acoustics, there is the “mass law” which in effect says the greater the mass, the greater its ability to not allow sound to pass through. For the same panel size and thickness, based on mass law, a denser panel will perform better than a less dense panel.

A material’s ability to minimize the passage of sound through it is defined as its sound transmission coefficient, which is the ratio of the sound energy transmitted through a material to the sound energy incident on the material. This is quantified by ASTM E336-23, Standard Test Method for Measurement of Airborne Sound Attenuation between Rooms in Buildings,5 which measures airborne sound attenuation between rooms in buildings, as field transmission loss (FTL) values.

For testing FTL through exterior walls and fenestration, testing is performed in according with ASTM E966-18, Standard Guide for Field Measurements of Airborne Sound Attenuation of Building Facades and Facade Elements,6 which measures the outdoor-indoor transmission loss (OITL) value.

Another value is the sound transmission class (STC), which rates the insulation of interior partitions against sound from different sources. To determine the STC for an acoustical barrier, the STL is recorded for a series of 16 frequency bands.

ASTM also has an outdoor-indoor transmission class (OITC) rating to evaluate the sound reduction of exterior partitions such as walls, windows, and doors exposed to transportation noise.

Both the OITC and STC values are intended only as a preliminary estimate of the acoustical properties of exterior and interior partitions. It is also important to note these two values are measuring different sounds and, therefore, are not interchangeable. A more accurate estimate should be based upon data from the entire STL curve. This becomes more important with partitions or glazing designed to exclude a very specific frequency range of intruding noise.

The STC level of a fenestration or cladding product determines its effectiveness in blocking the transmission of sound into a space. For example, an environment exposed to very loud sounds requires an STC rating of 45 or greater. If hearing non-intelligible speech is acceptable, then a rating of 35 to 40 is sufficient.

While different types of glass may offer good sound reduction capabilities, if the glass contains air leaks or cracks, it can significantly compromise acoustical quality. Further, glazing system components such as the operating sash, expansion joints, and partition joints provide pathways for sound waves to travel and should be minimized.

Glass has a number of key sound transmission-related properties:

- Sound reduction increases with increased glass thickness.

- Sound reduction somewhat decreases as the glass area increases, though typically not enough to make much of a difference in majority of the architectural glass sizes.

- Laminated glass is particularly effective for interior partitions because air pressure changes from sound bow or bend with laminated glass more easily than single glass of the same thickness. This “damping” property in laminated glass is particularly effective in cutting down sound transmission in the frequency range of the human voice.

Some design requirements may call for sound reduction capabilities over a narrow frequency span. For example, where traffic is a consideration, an average STL over the entire 125 to 4,000 Hz range should be used. Low frequencies should be emphasized since car, bus, and truck noise is the most intense when it is below 1,000 Hz and car horns are most intense in the 500 to 3,000 Hz range.

For facilities in the flight path of jet planes, using the average STL over the 125 to 4,000 Hz range is recommended. If the location is to the side of the runway, glass performance at 500 Hz is essential, whereas glass performance above 2,000 Hz is not so important.

If trains pass near the facility, frequencies below 1,000 Hz are the most significant, and the 125 to 700 Hz range does the best job at reducing whistle noise.

For two panes of glass, with air spaces ranging from 25.4 to 38 mm (1 to 1.5 in.), STL does not vary significantly. That said, glass/air space/glass combinations offer better performance when a sound-absorbing material, at least 25.4-mm (1-in.) thick, is used as a separator around the perimeter of the air space. There is no single material used specifically in these applications. It differs based on the construction of the building, available building materials, physical limitations of the space, etc.

Applying and testing acoustical ratings

Before delving into the test specification for measuring STL for windows, doors, skylights, and glazed wall sections, AAMA 1801 offers additional background on the application of OITC and STC ratings.

Whereas OITC has been widely used as the predominant single number acoustical rating for many years, it was never intended to assess a material’s ability to limit exterior noise from entering a building. Instead, OITC ratings are recommended for exterior fenestration products. It is also important to note the scope of AAMA 1801 does not include interior window or door assemblies.

Further, air leakage impacts acoustic performance. Consequently, air leakage—in addition to operating and latching force—must be measured to ensure acceptable performance of the unit before testing it for acoustical performance.

Regarding the test installation, the test specimens are installed into a test opening of a filler wall that has a higher STL than expected for the specimen being tested. A closed-cell foam isolator pad is placed on the bottom to support the test specimen and isolate it from the test opening. Then, a heavy mastic material, such as a duct seal compound, is used to seal the perimeter of the test specimen frame to the test opening on both sides.

All operable sash or panels should be opened and closed at least five times and then latched or locked prior to testing to ensure the tested units meet operational requirements.

The prescribed test methods and sequence of test should be performed in accordance with ASTM E1425, Standard Practice for Determining the Acoustical Performance of Windows, Doors, Skylight, and Glazed Wall Systems.7

Finally, tested products are classified and rated based on their acoustical performance in accordance with ASTM E1332-22, Standard Classification for Outdoor-Indoor Sound Attenuation.8 This standard provides a single number rating for sound transmission loss or noise reduction based on data that has been measured or calculated. The rating is based on 13 one-third-octave measurements that cover a range of 50 to 5,000 Hz. Each rating is dependent upon both the specimen and the sound spectrum. It is obtained by taking all the measurements and through calculation, a rating is obtained. The rating may be impacted by what individual frequencies are tested and the strength of signal for each. Attempting to explain all the intricacies of this data would be a separate discussion and would best be addressed by an acoustical engineer.

Acoustics matter

Acoustics are and continue to be a significant challenge to ensuring occupant comfort, optimizing learning and working conditions, and reducing stress. To accomplish this, architects and contractors require a better understanding of how sound travels and how the right fenestration can be specified and installed to limit sound transmission from the exterior.

These discussed documents serve as a great resource, spelling out the different values and testing protocols for acoustically rated fenestration.

Notes

1 Learn more by visiting the World Health Organization (WHO) at www.who.int/europe/news-room/fact-sheets/item/noise.

2 Refer to the IGMA TM-6000 standard at store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=6000.

3 Refer to the AAMA 1801 standard at store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=1801.

4 See the AAMA TIR-A1 standard at store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=A1.

5 Consult ASTM E336-23 at www.astm.org/e0336-23.html.

6 Consult ASTM E966-18 at www.astm.org/e0966-18a.html.

7 Learn more about ASTM E1425 at www.astm.org/e1425-14.html.

8 See ASTM E1332-22 at www.astm.org/e1332-22.html.

Author