The fabric-based alternative to metal duct

Metal duct has been the standard for HVAC air delivery for more than a century. However, there are less-costly alternatives to metal in most applications. Woven high-grade polyester fabric duct is a popular alternative for open architectural ceilings. While building codes do not allow designers to recess it in ceilings and walls, fabric duct for open architecture ceilings has gained a significant market share over the last few decades.

Amid today’s rising metal prices and shortages, fabric duct prices are less volatile, less expensive, and more available than metal. Contractors using fabric-based air distribution and air dispersion solutions are less vulnerable to the growing costs of HVAC manufacturing. Logistics are also less cumbersome, since fabric-air systems are lightweight and more compact, thereby taking up less freight space than conventional metal products.

High-quality fabric meets required standards, with the additional advantage of being flame retardant. Some fabrics can even be specified with antimicrobial properties.

Advantages of fabric duct

There are a host of applications suitable for fabric duct, which can make it more advantageous than its metal counterpart. While fabric duct is suitable for any application with an open architectural ceiling, its specification is particularly well-suited for gymnasiums, natatoriums, offices, healthcare, education, cold storage, and industrial uses, such as food processing.

Cost differences

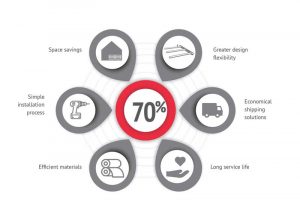

Besides lower material costs, fabric duct compares favorably to metal duct in terms of installation time, energy savings, aesthetics, air dispersion, and maintenance costs.

With respect to installation costs, fabric duct is often 75 percent less, depending on the diameter, ceiling height, and other factors. Contractors typically install both metal and fabric duct systems, up to 610-mm (24-in.) diameter, using standard scissor and boom lifts. However, as the metal duct diameters increase, the complexity, costs, necessary lift equipment, installation crews, and safety concerns increase significantly. The same crew, lifts, and equipment able to install a 508-mm (20-in.) diameter metal duct can install a 1524 mm (60-in.) or even a 2032 mm (80-in.) diameter fabric duct simply because it is up to 90 percent lighter in weight.

Further, fabric duct does not require the extensive test-and-balancing costs of metal duct. Fabric systems are factory balanced, and only require a damper at the metal-to-fabric transition to ensure the proper supply. For factory balancing, a fabric duct manufacturer receives the project consulting engineer’s specifications for airflow, velocity, direction, and other parameters, then custom builds those balanced attributes into the product at the manufacturing facility.

Another cost difference is seismic bracing, which is required in some geographical regions for metal duct systems to prevent sway damage on vertical suspension supports. Seismic bracing is not necessary for fabric duct because it weighs less than 3 kg/m (2 lb/ft) in most cases.

Prior to the pandemic, a general industry misconception was to assume fabric would be more expensive than metal in terms of material costs. On the surface, metal duct may appear less expensive, but it is not when considering all the required metal duct accessories. Fabric duct is designed, priced, and shipped as a complete system, which includes suspension systems. Contractors often compare lengths of metal duct to lengths of fabric and, when doing so, they do not consider the registers, boots, hanging hardware, potential painting or coatings, and insulation, which increases the price.

Battling condensation

Insulation is critical for condensation prevention in high humidity environments such as indoor pools and cannabis grow operations (CGOs). Fabric does not attract condensation, but cold metal does and, therefore, requires the added expense of interior or exterior insulation or insulation inside double-wall spiral metal duct.

Condensation prevention combined with antimicrobial fabrics is one reason designers of cannabis facilities and indoor pools prefer fabric versus metal duct. For example, Real Leaf Solutions (RLS) in Kalkaska, Michigan, retrofitted two 139-m2 (1500-sf) flowering rooms using fabric duct with six and eight-ton variable refrigerant flow (VRF) systems. Tom Beller, the company’s chief operations officer, believes this combination helped produce a harvest with a 20-percent yield improvement versus older rooms with metal duct and conventional air conditioning equipment.

RLS’s fabric duct solution incorporates a linear orifice array at the four and eight o’clock positions on each 508-mm diameter length. The fabric also disperses approximately 12 percent of the airflow through the duct’s permeable surface to prevent condensation. The factory-engineered permeability and linear dispersion result in a uniform 70.8 m3/minute (2500-cfm) air distribution per duct run which helps plants thrive.

In natatoriums, the use of fabric duct helps to prevent condensation and eliminates the need for metal duct coatings and periodic maintenance. For example, at the new $48 million Aquatic Center at Mylan Park (ACMP) in Morgantown, West Virginia, the contractor substituted fabric duct for the original design of polyvinyl chloride (PVC)-coated single-wall spiral metal duct. The switch reduced ductwork material costs by $55,000, according to Chris Myers, the general manager for design/build mechanical contractor A. Durer Inc. (ADI).