Outlining the advantages of fabric duct systems

by brittney_cutler | August 1, 2022 4:00 pm

[1]

[1]By Brian Refsgaard

The Covid-19 pandemic continues to unveil many global problems beyond its primary threat to health. Global trade is much lower than it was in the pre-pandemic world, and supply line shortages have caused a number of issues in several industries, especially the construction industry.

One issue is the meteoric rise of steel prices, which has caused significant construction industry challenges. Steel price escalation has skyrocketed with no end in sight. As the world continues to reopen, raw material prices are remaining high and many construction sectors, such as the HVAC industry, are feeling the pinch. Many unitary manufacturers, which depend on steel for cabinetry and framing, have reported price increases of up to 10 percent at least twice since the pandemic hit stride in March 2020. Likewise, steel HVAC ductwork has seen even higher price rises. The New York Stock Exchange’s (NYSE’s) American Steel Index XX:Steel was 539.41 on March 15, 2020, and peaked several times past 2000 last April before plateauing around 1500 this summer.

Raw materials cost surge: Why is it happening?

The short answer: COVID-19’s rampage across the globe closed thousands of businesses and put millions of people out of work. As industries and their workers learned to cope with the virus, economies started to come out of lockdowns and fueled the demand for raw materials, particularly in construction throughout 2021. Infrastructure, renovation, and new construction demanded raw materials when supplies were historically low.

Consequently, most of the world’s raw material producers are not able to ramp up quickly enough to pre-pandemic capacities due to pandemic-related closures and layoffs. The reopening pains were felt early in China, the major hub for producing manufacturing supplies comprised mostly of raw materials. In the U.S., even if materials were available, there have been worker shortages. Ironically, unemployment is still high; however, millions of job openings remain unfilled month after month.

According to cable network CNN Business, fundamental components affecting construction prices, such as iron ore, steel, and copper have soared to levels not seen since 2008. After reaching record levels in May and then retreating some, steel prices are 29 percent higher now compared to last September.[2] Aluminum, on the other hand, shows no signs of decline, as its price is up 34 percent year-over-year.

COVID-19 also affects logistics chain continuity. Some of the largest sea freight channels, such as ports in India, continue their bottlenecks which hinder worldwide material distribution.

[3]

[3]How raw materials shortages affect HVAC

The COVID-induced supply-and-demand crunch and logistics bottlenecks did not give a pass to the HVAC industry, as it depends on both to get its products to market. Steel prices have partially affected the HVAC industry, most notably in ductwork. A majority of HVAC ductwork is galvanized steel, with some special applications using aluminum, which is more expensive.

Depending on the HVAC industry segment, prices increased from six to 33 percent in the last year. This trend is expected to continue for months, if not years. The global HVAC market is forecast to grow by at least 6.72 percent by 2025[4], with most of this growth attributed to the rising prices of manufacturers.

In addition to steel and aluminum, other necessary HVAC components such as paint, coatings, and chemicals are also experiencing near-record price increases.

As lead times become longer, now is a great time for contractors to consider alternative HVAC solutions to save money, shorten install time, and increase performance.

The fabric-based alternative to metal duct

Metal duct has been the standard for HVAC air delivery for more than a century. However, there are less-costly alternatives to metal in most applications. Woven high-grade polyester fabric duct is a popular alternative for open architectural ceilings. While building codes do not allow designers to recess it in ceilings and walls, fabric duct for open architecture ceilings has gained a significant market share over the last few decades.

[5]

[5]Amid today’s rising metal prices and shortages, fabric duct prices are less volatile, less expensive, and more available than metal. Contractors using fabric-based air distribution and air dispersion solutions are less vulnerable to the growing costs of HVAC manufacturing. Logistics are also less cumbersome, since fabric-air systems are lightweight and more compact, thereby taking up less freight space than conventional metal products.

High-quality fabric meets required standards[6], with the additional advantage of being flame retardant. Some fabrics can even be specified with antimicrobial properties.

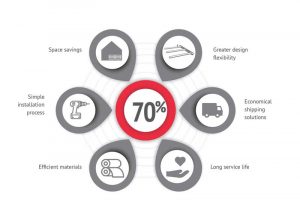

Advantages of fabric duct

There are a host of applications suitable for fabric duct, which can make it more advantageous than its metal counterpart. While fabric duct is suitable for any application with an open architectural ceiling, its specification is particularly well-suited for gymnasiums, natatoriums, offices, healthcare, education, cold storage, and industrial uses, such as food processing.

Cost differences

Besides lower material costs, fabric duct compares favorably to metal duct in terms of installation time, energy savings, aesthetics, air dispersion, and maintenance costs.

[7]

[7]With respect to installation costs, fabric duct is often 75 percent less[8], depending on the diameter, ceiling height, and other factors. Contractors typically install both metal and fabric duct systems, up to 610-mm (24-in.) diameter, using standard scissor and boom lifts. However, as the metal duct diameters increase, the complexity, costs, necessary lift equipment, installation crews, and safety concerns increase significantly. The same crew, lifts, and equipment able to install a 508-mm (20-in.) diameter metal duct can install a 1524 mm (60-in.) or even a 2032 mm (80-in.) diameter fabric duct simply because it is up to 90 percent lighter in weight.

Further, fabric duct does not require the extensive test-and-balancing costs of metal duct. Fabric systems are factory balanced, and only require a damper at the metal-to-fabric transition to ensure the proper supply. For factory balancing, a fabric duct manufacturer receives the project consulting engineer’s specifications for airflow, velocity, direction, and other parameters, then custom builds those balanced attributes into the product at the manufacturing facility.

Another cost difference is seismic bracing, which is required in some geographical regions for metal duct systems to prevent sway damage on vertical suspension supports. Seismic bracing is not necessary for fabric duct because it weighs less than 3 kg/m (2 lb/ft) in most cases.

[9]

[9]Prior to the pandemic, a general industry misconception was to assume fabric would be more expensive than metal in terms of material costs. On the surface, metal duct may appear less expensive, but it is not when considering all the required metal duct accessories. Fabric duct is designed, priced, and shipped as a complete system, which includes suspension systems. Contractors often compare lengths of metal duct to lengths of fabric and, when doing so, they do not consider the registers, boots, hanging hardware, potential painting or coatings, and insulation, which increases the price.

Battling condensation

Insulation is critical for condensation prevention in high humidity environments such as indoor pools and cannabis grow operations (CGOs). Fabric does not attract condensation, but cold metal does and, therefore, requires the added expense of interior or exterior insulation or insulation inside double-wall spiral metal duct.

Condensation prevention combined with antimicrobial fabrics is one reason designers of cannabis facilities and indoor pools prefer fabric versus metal duct. For example, Real Leaf Solutions (RLS) in Kalkaska, Michigan, retrofitted two 139-m2 (1500-sf) flowering rooms using fabric duct with six and eight-ton variable refrigerant flow (VRF) systems. Tom Beller, the company’s chief operations officer, believes this combination helped produce a harvest with a 20-percent yield improvement versus older rooms with metal duct and conventional air conditioning equipment[10].

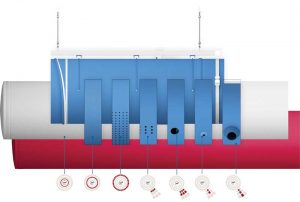

[11]

[11]RLS’s fabric duct solution incorporates a linear orifice array at the four and eight o’clock positions on each 508-mm diameter length. The fabric also disperses approximately 12 percent of the airflow through the duct’s permeable surface to prevent condensation. The factory-engineered permeability and linear dispersion result in a uniform 70.8 m3/minute (2500-cfm) air distribution per duct run which helps plants thrive.

In natatoriums, the use of fabric duct helps to prevent condensation and eliminates the need for metal duct coatings and periodic maintenance. For example, at the new $48 million Aquatic Center at Mylan Park (ACMP) in Morgantown, West Virginia, the contractor substituted fabric duct for the original design of polyvinyl chloride (PVC)-coated single-wall spiral metal duct. The switch reduced ductwork material costs by $55,000, according to Chris Myers, the general manager for design/build mechanical contractor A. Durer Inc. (ADI).[12]

Fabric duct also decreased labor costs for the 8361-m2 (90,000-sf) facility and reduced trade stacking, because it installs up to 60-percent faster than metal duct. The expedited installation cut six to eight weeks from the ductwork installation time, says Myers. Further, the fast-tracking allowed other trades to complete their work sooner than if conventional metal ductwork had been used. The fabric duct’s single-point aluminum suspension system serving the Olympic-sized competition pool and six-lane diving well was installed in just 10 days. Afterward, only five days were needed to hang the 299-m (980-ft) of fabric ductwork, consisting of 2438-mm (96-in.) diameter headers and branches ranging from 1219- to 1422-mm (48- to 56-in.) in diameter.

Energy efficiency

Studies have shown fabric duct uses less energy than metal because its air dispersion methodology provides uniform distribution throughout a space with fewer dead or static spots. As a result, the designer can achieve a consistent temperature, and the mechanical equipment runs less.

One study, “Thermal Comparison Between Ceiling Diffusers and Fabric Ductwork Diffusers for Green Buildings,” compared the heating performance of metal versus fabric duct at various flow rates.[13] Conducted by the Department of Mechanical Engineering at Iowa State University, in Ames, Iowa, the study showed that fabric duct heats rooms faster, more uniformly and, as a result, more efficiently. The fabric system was 24.5 percent more efficient than the ceiling metal diffuser system. The latter fell short because a significant fraction of distributed air stayed along the ceiling. The fabric system’s higher velocities and multiple outlets resulted in more energy absorption by the room. Systems reach set points more quickly which decreases the mechanical system’s runtime.

Fabric can also provide an unlimited number of linear air dispersion vents ranging anywhere from micro-perforations to orifices of several inches in diameter. Unlike spiral metal duct, with registers every 1.5 to 3 m (5 to 10 ft), distributing large volumes of air and requiring reducers, fabric duct’s linear vents distribute air along the entire length.

Consequently, fabric duct also has less friction loss than metal due to fewer reducers. This also creates a more uniform static pressure without requiring reducers.

In addition to linear vents, engineers may often design fabric duct with precise surface permeability via a standalone distribution method or in combination with any vent combinations. This also promotes more uniform airflow, temperatures, and efficiency.

[14]

[14]Fabric aesthetics

While fabric duct can be more aesthetic than the external ribbing and protruding registers common with spiral metal duct, it can sag and deflate when the air handler is off or operating at partial capacity. As a result, the fabric duct industry has taken great strides to reverse this disadvantage by using internal and external support systems which give it a near or 100-percent inflated appearance.

Shape retention innovations include metal or fiberglass internal or external support hoops. Depending on the manufacturer, these supports are factory installed and do not require assembly onsite; however, there are some types that may require additional labor. Visible external hoops affect the streamlining of the duct surface, but do not add friction loss. While internal hoops are not visible from the outside, they can add significant friction loss, if left exposed inside the duct. However, if the internal hoops are enclosed in fabric sleeves, there will be a significant decrease in friction loss.

[15]

[15]Another aesthetic advantage of fabric systems is the diversity of colors and patterns that are available. One must paint exposed metal duct, typically in the field, when colors are important to the interior design. For instance, owners regularly specify corporate and school colors, logos, and even patterns on fabric duct systems. Architects can select essentially any repetitive pattern, such as coffee beans for a coffee shop, fruits and vegetables for a grocery store, or camouflage for an outfitter store to supplement or enhance the interior design theme. These same patterns and logos may be cost-prohibitive for metal duct.

Fabric duct serves the education and recreation facility market, specifically gymnasiums and other athletic spaces which are well suited to fabric duct. Activities in gymnasiums typically take a toll on metal duct. Dents and condensation typically perpetuate a long span of corrosion, ending metal duct’s lifecycle prematurely. Further, metal duct coatings are not always reliable. Fabric duct does not require special coatings to protect against corrosion or rust.

For example, Park Hill Baptist Church in North Little Rock, Arkansas, needed to replace its Christian Activities Center’s (CAC’s) gray coated 660-mm (26-in.) diameter metal HVAC duct after several unsuccessful recoating attempts. The double-wall spiral duct had become a dented, dirty, flaking eyesore for the 1500-member church.

Replacement with metal duct was estimated at $100,000 for demolition and installation labor/materials, not to mention a lengthy weeks-long downtime.

[16]

[16]Instead, the church installed 711-mm (28-in.) diameter black fabric duct which the fabricator custom manufactured and shipped directly to the jobsite. Once the contractor anchored the system’s suspension system, installation required only a few hours of sliding the fabric duct clips into the suspension system and zippering lengths together. In total, the fabric duct cost the church less than $10,000 for materials and significantly less for the fabric duct installation using in-house staff.

Conclusion

Everyone in construction and the HVAC business is feeling the consequences of the global price rise of raw materials. It is unsurprising to see providers of conventional solutions adapt by raising their prices. Unfortunately, contractors, engineers, and others in the construction chain ecosystem are taking the hardest financial hit. Now is a great time to consider a high-quality fabric-based alternative to metal duct.

The pandemic has been a devastating event; however, there might be a silver lining to this dark cloud. The effects of COVID-19 might prompt the construction industry to look elsewhere for suitable, alternative building materials, which will also benefit building owners now and in the future.

Author

Brian Refsgaard is president of FabricAir in Suwanee, Georgia, a manufacturer of fabric air dispersion duct for almost 50 years. Refsgaard joined FabricAir’s sales staff in 1990 and became the firm’s CEO in 1999. Today, the FabricAir Group operates 13 sales companies globally and offers a full line of fabric duct and accessories. Refsgaard can be reached at br@fabricair.com.

Brian Refsgaard is president of FabricAir in Suwanee, Georgia, a manufacturer of fabric air dispersion duct for almost 50 years. Refsgaard joined FabricAir’s sales staff in 1990 and became the firm’s CEO in 1999. Today, the FabricAir Group operates 13 sales companies globally and offers a full line of fabric duct and accessories. Refsgaard can be reached at br@fabricair.com.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/FabricAir_20161002_211213-Type-2-and-Type-1.jpg

- September.: http://tradingeconomics.com.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/FabricAir_DSC01657.jpg

- 2025: http://researchandmarkets.com.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/9-The-6-key-elements-of-fabric-duct-savings.jpg

- standards: https://www.nfpa.org/assets/files/AboutTheCodes/90B/90B_A2017_AIC_AAA_SecondDraftReport.pdf.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/5-Mylan-Park-competition-pool-1.jpg

- 75 percent less: https://www.constructionspecifier.com/fabric-duct-solves-hvac-engineering-challenges-for-48-m-aquatics-center.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/3-Before-shot-of-Park-Hill-CAC-flaking-metal-duct.jpg

- air conditioning equipment: http://hvacinsider.com/michigan-cannabis-grow-op-increases-yields-with-hvac-system-retrofit.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/4-After-Shot-Park-Hill-CAC-fabric-duct.jpg

- (ADI).: http://achrnews.com/articles/143470-project-files-episode-29-aquatic-center-at-mylan-park.

- flow rates.: http://news.engineering.iastate.edu/2012/05/25/mechanical-engineering-student-makes-discovery-in-ductwork.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/8-Cannabis-Grow-Facility.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/10-without-air-dispersion-descriptions.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2022/07/NANTIER_Chocolate-Factory_09.jpg

Source URL: https://www.constructionspecifier.com/outlining-the-advantages-of-fabric-duct-systems/