Evolution of ASTM E2307

Curtain wall design became common in commercial construction over the past 40 years, but there were no consensus fire test standards or testing procedures for fire protection of exterior curtain walls and floor-to-wall perimeter voids until 2004. The legacy model codes included only cursory mention of this building issue, so architects, designers, contractors, and code officials often adopted untested and uncertain solutions. Later, more effective products were developed and tested for curtain wall fire protection in accordance with ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials. However, because that standard does not specifically address these unique construction joints, codes only partially addressed the fire risk.

In 2004, ASTM E2307 was developed. Evaluating the interface between a fire-resistance-rated horizontal assembly and an exterior curtain wall, this test method is used to measure and describe the response of materials, products,

or assemblies to heat and flame under controlled conditions. However, it does not by itself incorporate all factors required for the fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions, using a test structure called the Intermediate-scale, Multi-story Test Apparatus (ISMA).

The ISMA test simulates fire exposure in a high-rise structure where, as the fire intensifies and positive pressure builds, a fire-induced window break occurs, allowing oxygen to feed the flames. The method is meant to simulate a fire in a post-flashover condition in a compartment venting to the exterior.

The provisions of ASTM E2307 are intended to restrict the interior vertical passage of flame and hot gases from one floor to another at the location where the floor intersects the exterior wall assembly. Its use is mandated by U.S. building codes, thereby requiring the protection of openings between a floor and an exterior wall assembly to provide the same fire performance as that required for the floor.

U.S. building codes

Since their 2006 editions, both IBC and NFPA 5000, Building Construction and Safety Code, have referenced ASTM E2307 as a means of providing perimeter fire barrier joint protection installed in the space between an exterior wall assembly and a floor assembly. The 2015 IBC Section 715.4 requires where fire-resistance-rated floor or floor/ceiling assemblies are installed, voids that are created at the intersection of the exterior curtain wall assemblies and the floor assemblies be sealed with an approved system to prevent the interior spread of fire. It further requires those systems be tested in accordance with ASTM E2307 to provide an F rating for a period not less than the fire-resistance rating of the floor assembly.

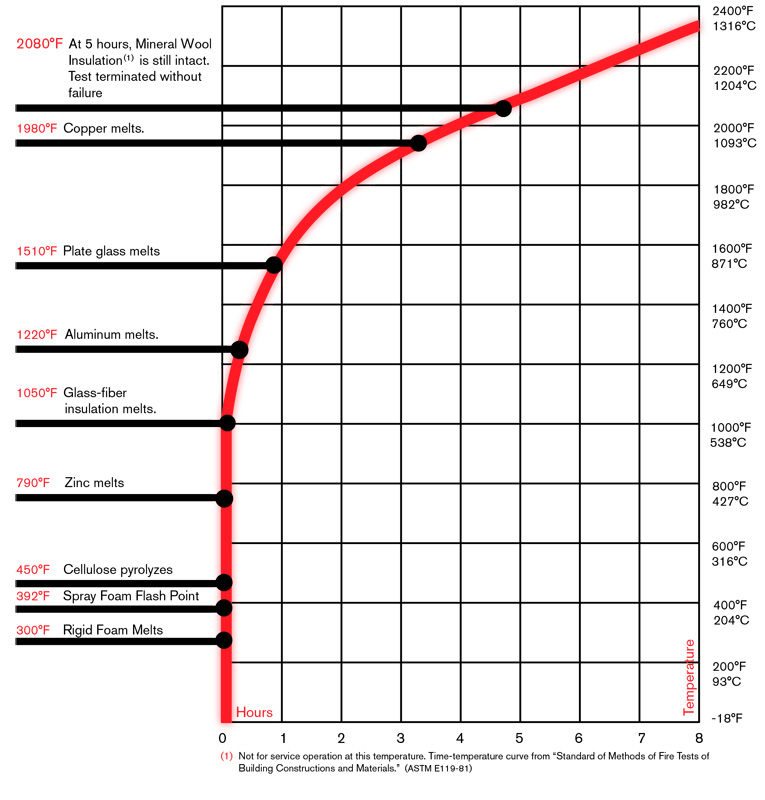

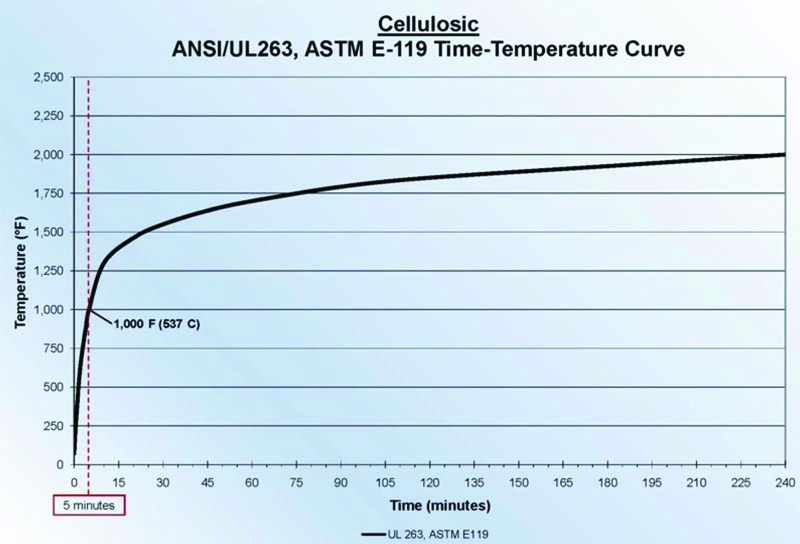

A notable exception to the IBC requirement for ASTM E2307 is for glass curtain wall assemblies, when the vision glass extends to the finished floor level (i.e. full-height glass). In those cases, IBC alternatively permits the perimeter void to be protected with an approved material capable of preventing the passage of flame and hot gases sufficient to ignite cotton waste where subjected to ASTM E119 time-temperature fire conditions for the same duration as the fire-resistance rating of the floor assembly.

Where the joint between walls involves a non-fire-resistance-rated floor and an exterior curtain wall, there is no reason to try to maintain a fire-resistance rating with a rated joint system. However, spread of smoke is a concern, and, therefore, the code calls for a tight joint to protect the rapid spread of smoke from a floor of fire origin to other floors of the building. Consequently, IBC and NFPA 5000 still require where a fire-resistance-rated floor intersects with a nonrated spandrel wall, the void space must be protected by an approved joint system.