Photoluminescent Egress: A Critical Safety Specification

History proves performance

Prior to the 1990s, PL lighting was more of a novelty and not considered bright or long-lasting enough to function as an egress marking. Emergency electrical lighting was considered sufficient for providing lighting and exit strategies during catastrophes.

However, a catastrophe opened new discussions regarding the possibilities of PL egress markings. The 1993 World Trade Center bombing provided a sobering indication electrical systems alone were insufficient because the building’s emergency lighting system was damaged, impeding egress for some of the occupants. It became clear egress routes needed to be designated with markings not reliant on external power sources. Around this time, significant advancements were made in PL technology enabling it to provide a longer-lasting afterglow. Consequently, the World Trade Center was one of the first facilities to employ PL as an egress path marker in the late 1990s.

In 2001, the 9/11 World Trade Center attack put the PL system to the real test. Survivors listed the PL markings as one of the top three things that helped them exit the building safely. At the Pentagon where PL demarcation was not yet in use, survivors reported difficulty exiting. (For more information, read the article, “A Brief History of Photoluminescent Marking,” published by Building Operating Management Magazine.)

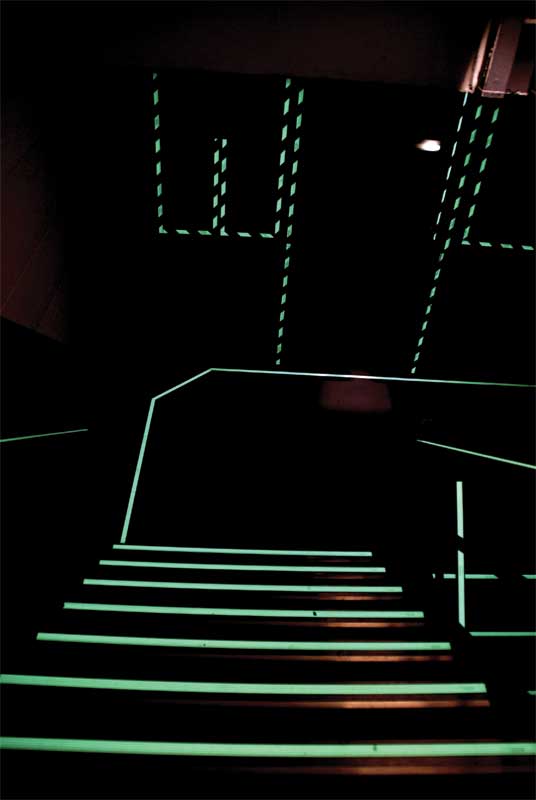

The 9/11 attack prompted a number of PL installations and requirements for the material in building codes. For example, the United Nations installed PL pathway markings in 2003; New York City passed Local Law 26, which mandated PL pathway markings in all high-rise office building stairwells by 2006; and the International Code Council (ICC) adopted a PL pathway marking in a variety of building types as part of its 2009 IBC.

Selecting a PL system

While PL is required in many building codes, and its luminance performance is governed by test standards, there are still important decisions specifiers and contractors must make. One such decision is the quality of PL product. If people are to egress the building safely, not only days, but years after the material has been installed, then the durability of the specified product has a major impact on occupant safety. Unfortunately, life-safety products are often downgraded as a part of larger efforts to reduce total project cost. While looking for cost-saving opportunities is good from a project management standpoint, it should never compromise a building’s life-safety systems.

Since IBC’s adoption of PL egress requirements in 2009, many code-compliant products have entered the market, providing luminescent markings on a wide range of media from thin tape/films to extruded plastic or aluminum.

Tapes/films typically have an ultra-thin adhesive coating on one side for easy peel-and-stick installation. They are less expensive but require more maintenance. They excel in adhesion to smooth substrates, such as metals, but can have difficulties on concrete where the surface is not as smooth as metals and requires careful cleaning to remove dust. Further, they wear much quicker under foot traffic. The use of these products in such an application can result in worn or missing markings, which leaves the intended PL egress pathway poorly defined and subject to a potential code violation and liability. The expected short life cycle of tapes/films leaves the facility unprotected if the building maintenance staff does not carefully maintain and reapply damaged tape/film sections.

Coated aluminum strips provide a much stronger, longer-lasting marking system for foot traffic applications. In contrast to the thin adhesive film, these products are either mechanically fastened or adhered in place with a viscous construction adhesive. The aluminum backing provides a robust substrate for the PL material withstanding the daily abuse of foot traffic. Additionally, these strips can be mounted into a stair nosing, thereby protecting the stair edge and increasing its slip resistance. Most manufacturers provide extended warranties for this type of product and some guarantee effective charge/glow cycles for as long as 25 years.

Another important consideration is the ability to keep the PL material clean. If not rigorously maintained, products trapping dirt onto the PL surface will quickly suffer loss in performance. This is the case with products integrating the PL pigment directly into a rough tread insert. While this material is ideal for providing slip resistance, it should be used in conjunction with separate, smooth PL strips (e.g. aluminum demarcation strips) featuring a smooth coating that does not actively collect dirt and is easy to wipe clean.

Finally, areas outside of code-driven egress applications such as stairs in stadiums, plazas, and other outdoor facilities can be effectively marked with PL systems. In these cases, it is important to ensure the PL strip has been tested to UL 1994 for outdoor use. Since most products were developed strictly with indoor egress applications in mind, there are few materials designed to withstand ultraviolet (UV) light exposure. Products listed for outdoor use in accordance with UL 1994 are required to be exposed to UV light for an extended period of time and suffer no more than 10-percent loss in luminance performance.