Providing the perfect platform

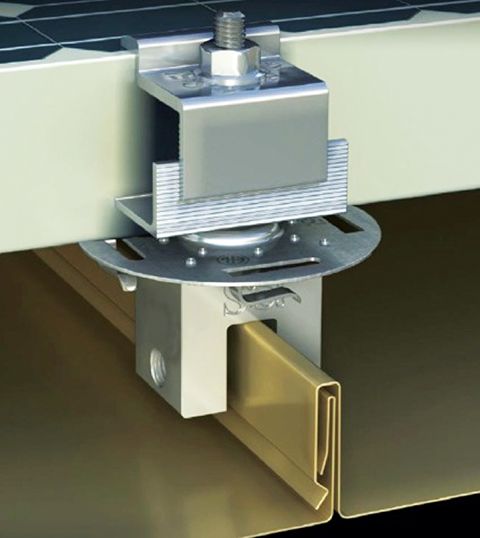

As mentioned, the standing seam roof utilizes non-penetrating seam clamps to anchor PV modules and all other ancillary roof-mounted equipment (Figure 6). Thousands of installations have been completed using these clamps with zero roof penetration (Figure 7). These systems are easier and quicker to install than other mounting methods with no chance of leaks. Some seam clamps are UL- or Intermark ETL-listed for electrical continuity; they meet UL 2703, Standard for Mounting Systems, Mounting Devices, Clamping/Retention Devices, and Ground Lugs for Use with Flat-plate Photovoltaic Modules and Panels, for both mounting and electrical bonding and ETL 1703-listed for electrical bonding. (These assemblies connect the modules together as an electrically connected/bonded unit.)

Design professionals should also consider the rooftop accessories that come with a PV system. With non-penetrating seam clamps, combiner boxes, and conduit mounted penetration-free (and without ballast), the savings are substantial. The process is also accomplished at about one-third the mounting expense of other methods. It often saves about 15 percent of total system cost—in terms of first dollar costs, not over the building’s lifecycle.

Other advantages with metal roofs

Standing seam metal roofing also offers advantages in terms of recycled material content. Further, they can create an excellent shade effect—the configuration creates a plenum where air, though stack effect, is actually drawn under the PV panel and exhausts up. This keeps the modules cooler so they are more efficient. Due to the shading effect, roof temperatures are about 33 percent cooler as well. (This figure varies by roof solar absorption and reflection based on the assembly’s color and pigment chemistry.)

Metal roofs are typically easy to install, which translates to lower installed costs. They also prevent fungal growth and offer heat-reflective capabilities. Metal roofs have a lower propensity to collect dirt (which is an organic food source) due to their coefficient of friction (i.e. lower slip)—therefore, they offer a less-friendly environment for fungal growth.

These benefits, coupled with the freedom from roof penetrations that could potentially violate warranty, make standing seam metal roofs suitable not only for projects that need to be solar-ready, but buildings of all types.

Harry J. Lubitz, CSI, CDT, is the architectural and national accounts manager for S-5! Metal Roof Innovations Ltd. (Colorado Springs, Colorado). He works with the design community to develop and improve architectural specifications for metal roofs and attachment systems. Lubitz has more than 25 years of experience in the building materials industry, is active in numerous architectural and professional organizations including CSI, and has served as an adjunct faculty member at Lord Fairfax Community College in Virginia. He can be reached at hlubitz@S-5.com.