Planning a Solar-ready Roof: Advantages with standing seam metal assemblies

by Katie Daniel | November 5, 2015 3:05 pm

[1]

[1]by Harry J. Lubitz, CSI, CDT

Last year, the California Energy Commission introduced new energy-efficient standards for all newly built residential and commercial structures. Essentially, ‘solar-ready roofs’ will be required on all new construction. While home and building owners are not required to install solar panels at the time of construction, their roofs must be prepared if they choose to install them in the future.

Following California’s lead, more states and municipalities are expected to require ‘solar-ready’ assemblies [2]going forward. Whether mandated or not, it is a good idea to understand what can be done to minimize costs and keep the option to add photovoltaics (PVs) down the road without too many headaches.

The best time to think about a solar roof plan is during the design stage; pre-planning is a must for an installation during the build or sometime in the future. This entails developing a review that focuses on optimizing the design and power production while minimizing the initial and longer-term costs. To this end, this article looks at the economics of opting for a membrane or metal roof in terms of outlasting the PV array above it.

[3]

[3]Orientation and roof pitch

Regardless of roofing material, there are a few general rules that can help maximize the power production of a PV system. For example, the general orientation of the building can be a very important factor. When steeper slopes are involved, south-facing roof surfaces are ideal (Figure 1). When this is impossible, southwest or southeast can also be good options.

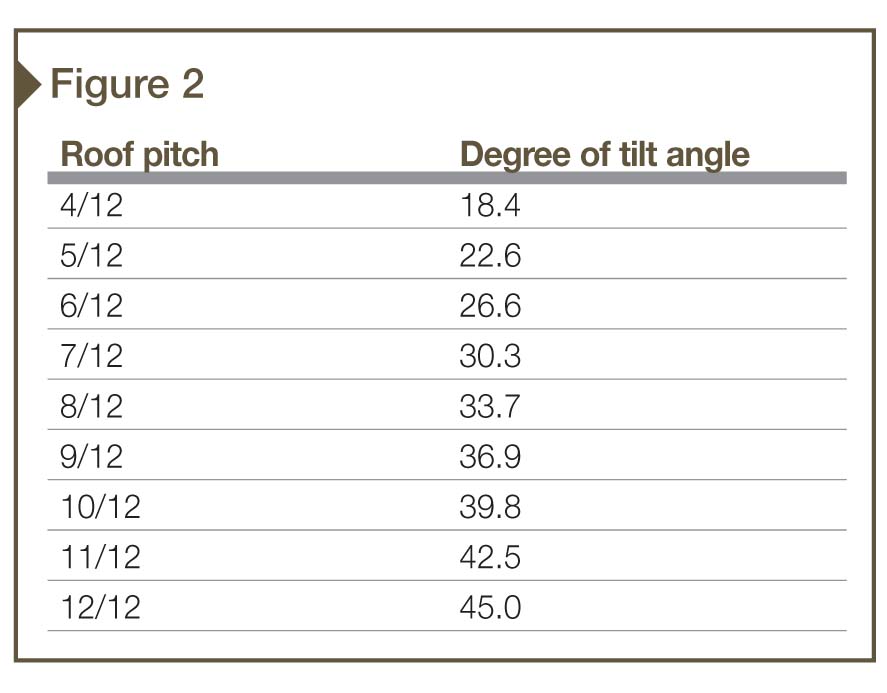

Orientation is not as important for very low slope roofs (i.e. five degrees or less). It is important to note the solar community uses angle in degrees while the roofing community uses pitch (Figure 2).

Modules are normally installed planar to the roof surface on steep roofs, and planar or very slightly tilted on low slope applications. Aggressive tilting of modules is seldom done anymore primarily due to economic considerations adversely affecting payback periods, and also due to adverse wind effects. Tilted systems are still used in very northern geographies, or on some roofs not oriented to the south. It is a delicate balance of increased cost versus increased power production.

[4]

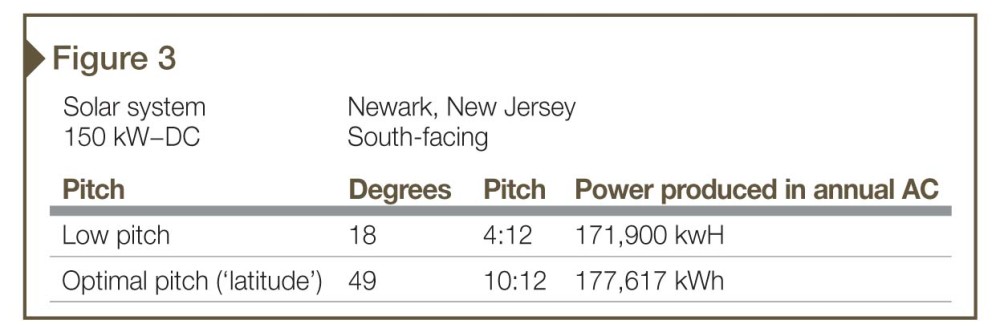

[4]In many cases, the roof pitch is pre-determined and cannot be modified. In theory, the best pitch is the latitude of the jobsite, but in practice this is seldom the case. A lower-than-optimal pitch is not as critical as orientation—the difference in power production is nominal. The increase in power production is not usually worth the premium cost of unusually steep pitches, unless the steeper slope is also an intentional design element. Even a 10 percent increase in power production does not usually warrant the added cost of achieving it (Figure 3).

Shading

The best design for the solar system is an unobstructed roof area (or areas) with no shading issues. Building components such as plumbing stacks, skylights, chimneys, and side walls can create shadows on the solar system. To eliminate shadows, the solar system design would be modified to accommodate any of these conditions. Consideration should also be given to any future buildings that could cast a shadow on the system or plants, like trees near the building.

[5]

[5]After the building design is finalized, there will be a specific area (the ‘solar zone’) that hosts the maximum number of modules or laminates that can fit on the roof. Issues that will be considered and reviewed include:

- code setbacks (e.g. prescription by federal, state, or local code authorities requiring egress for firefighting or setback from roof edges/corners to protect from wind uplift effects);

- rooftop equipment (e.g. a 1.2-m [4-ft] HVAC unit means space loss);

- roof access for maintenance and fire-fighting;

- desired array size; and

- space loss due to wire management.

Calculating ROI

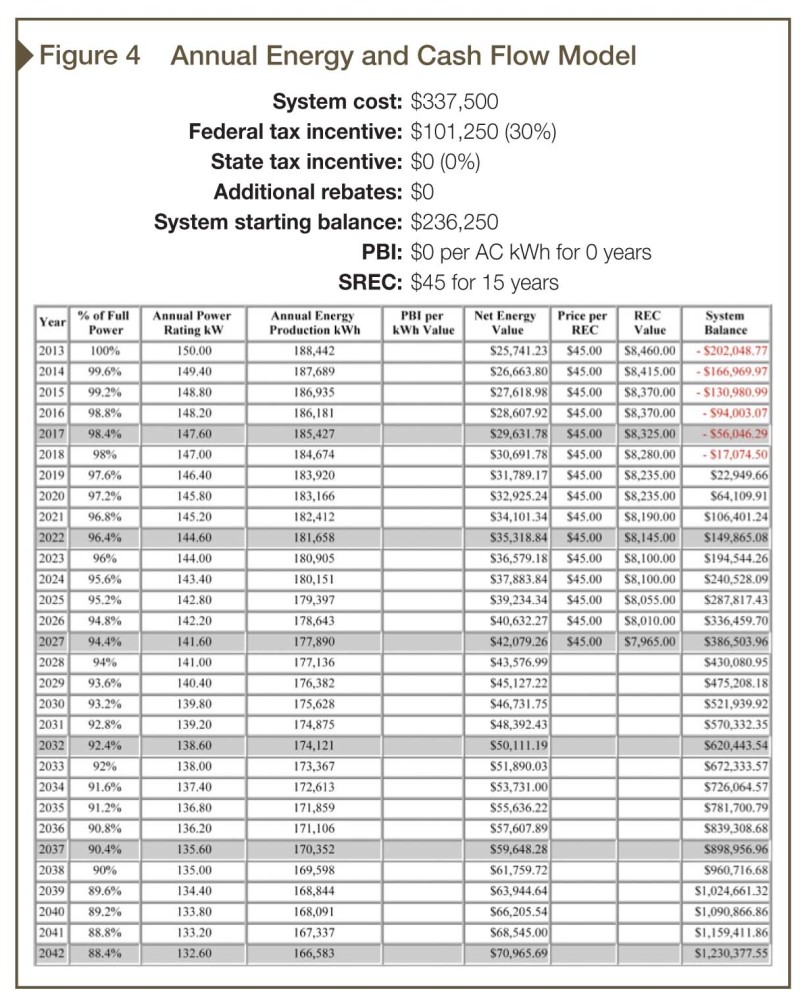

Attention to all the details in designing a solar system is crucial to achieve the most power production and to run an accurate return on investment (ROI) for the system. Sophisticated software currently available enables accurate prediction of the expenses, computing all project-specific variables including maintenance, sun-hours, system efficiency, energy cost, and cost escalation. With a basic ROI, the owner system designer and owner can accurately evaluate whether the proposition makes financial sense (Figure 4).

[6]

[6]For example, if the net system cost after a tax credit is $236,250 (original net investment was $337,500), and the PVs become ‘cash-positive’ in their sixth year, the ROI is the positive cash flow for the balance of the service life. In this particular hypothetical case, the payback at the end of 25 years (i.e. warranted period for solar modules) is $1,230,377. However, modules will typically have a longer service life than their warranty—at the end of 30 years, the ROI would be $1,585,377. If the system is still producing power after 35 years, the return on investment would be $1,940,377. This sounds like a really good deal, but it is very important to remember the costs of roof replacement are not being factored in.

The roof, after all, is the solar mounting platform. This means beyond knowing the life expectancy of the PV panels, it is absolutely critical to know the ramifications of the roofing assembly type, its service life, replacement costs, and whether it was included in the financial proforma.

Roofing material versus service life

Generally, a module’s warranted life is approximately 25 years, but the products themselves often exceed three decades of use. The service life of the roof should exceed the service life of the solar system. Otherwise, it needs to be replaced—a move that necessitates the de-commission, removal, and re-assembly of the solar system. This presents serious financial and logistic impacts beyond the cost of a traditional membrane roof replacement.

The mean service duration of conventional roofing materials can range. Survey results[7] published by Carl Cash of Simpson, Gumpertz & Heger (SGH) in 2005 suggest the following life expectancies:

- built-up roof (BUR): 19.8 years;

- atactic polypropylene (APP): 16.1 years;

- styrene-butadiene-styrene (SBS): 17.7 years; and

- thermoplastic polyolefin (TPO): 13.6 years. (Some specific TPO products are warranted for 15, 20, or 25 years, however.)

The service life of other commercial roof types typically falls between 12 and 20 years At that point, they have to be replaced, even though the solar array atop their assembly is still performing.

This means the reroofing work would involve:

- removing the modules;

- removing the mounting and racking system;

- de-commissioning the system during the reroof;

- traditional re-roof work;

- re-installing the PV system; and

- re-commissioning the system.

When combined with the fact PV components will likely be damaged and require replacement, and the loss of power production during the work, this becomes a very expensive process.

It is vital to understand the relative costs of the roof asset (i.e. the mounting platform) and the solar asset (i.e. the revenue generator), as they have a profound effect on each other. For example, with a new TPO roof of significant size (i.e. 2322 m2 [25,000 sf] or larger), covered with PV, the initial cost is approximately $30/m2 ($3/sf). Calculating the value of the solar array at about 12 Watts per square foot at a typical cost of $2.50/Watt places the cost of the array at $300/m2 ($30/sf). The initial cost of solar is approximately 10 times that of a conventional roof. The aggregated cost of this total system is $330/m2 ($33/sf).

The cost of reroofing is not only the cost of the re-roof, but also the expense of dismantling and reassembling the solar array, in addition to the loss of power production while this process takes place. Estimating the re-roof cost at $20/m2 ($2/sf) and the cost of removing and reinstalling the solar array at 130/m2 ($13/sf), the total is $150/m2 ($15/sf) for the complete re-roof. This means the aggregated cost of this total system over time is now $480/m2 ($48/sf).

While these estimates are based on the previously mentioned Cash survey, along with professional experience and current market costs, the final numbers will vary based on state, union or non-union labor, and the project’s size and parameters.

[8]

[8]Standing seam metal roofs

This calculation can be contrasted with another example—a 33-year-old Galvalume standing seam metal roof (Figure 5). Recent field studies[9] gathered empirical data from 14 roofs aged over 30 years in five different U.S. climate zones affirm such roofs can be in the 60- to 70-year range, far outliving the life of a solar PV system.

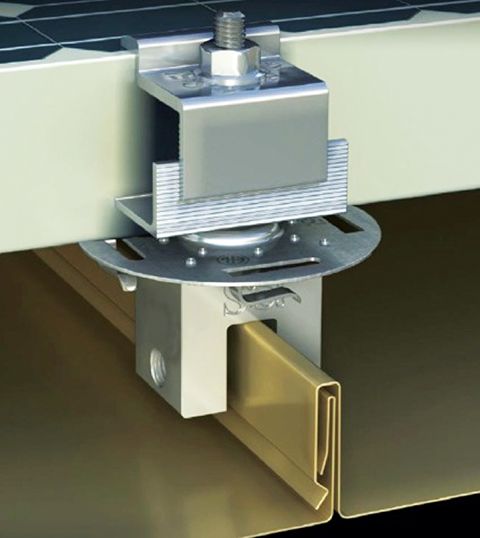

There are also other benefits to specifying a standing seam metal assembly for a roof that needs to be solar-ready. For example, instead of expensive ballasted or penetrating racking systems required for membrane (or any non-metal) roofs, clamps can be used to mount the system.

Mounting methods to standing seam are actually lower in cost—15 percent less in some cases—than with conventional roof types. In many instances, enough money is saved in mounting costs to pay for the higher-grade roof, and still have net savings.

The cost of a mid-sized, low-slope commercial standing seam roof is about $40/m2 ($4/sf) and, as mentioned, it should outlive the solar array, avoiding all the costs of roof replacement. Consequently, the aggregated cost of ownership of the roof over the life of the solar array is approximately $310/m2 ($31/sf) versus the aggregated cost of ownership over the same time span of $480/m2 ($48/sf) on a conventional commercial membrane roof.

[10]

[10] [11]

[11]

Providing the perfect platform

As mentioned, the standing seam roof utilizes non-penetrating seam clamps to anchor PV modules and all other ancillary roof-mounted equipment (Figure 6). Thousands of installations have been completed using these clamps with zero roof penetration (Figure 7). These systems are easier and quicker to install than other mounting methods with no chance of leaks. Some seam clamps are UL- or Intermark ETL-listed for electrical continuity; they meet UL 2703, Standard for Mounting Systems, Mounting Devices, Clamping/Retention Devices, and Ground Lugs for Use with Flat-plate Photovoltaic Modules and Panels, for both mounting and electrical bonding and ETL 1703-listed for electrical bonding. (These assemblies connect the modules together as an electrically connected/bonded unit.)

Design professionals should also consider the rooftop accessories that come with a PV system. With non-penetrating seam clamps, combiner boxes, and conduit mounted penetration-free (and without ballast), the savings are substantial. The process is also accomplished at about one-third the mounting expense of other methods. It often saves about 15 percent of total system cost—in terms of first dollar costs, not over the building’s lifecycle.

Other advantages with metal roofs

Standing seam metal roofing also offers advantages in terms of recycled material content. Further, they can create an excellent shade effect—the configuration creates a plenum where air, though stack effect, is actually drawn under the PV panel and exhausts up. This keeps the modules cooler so they are more efficient. Due to the shading effect, roof temperatures are about 33 percent cooler as well. (This figure varies by roof solar absorption and reflection based on the assembly’s color and pigment chemistry.)

Metal roofs are typically easy to install, which translates to lower installed costs[12]. They also prevent fungal growth and offer heat-reflective capabilities[13]. Metal roofs have a lower propensity to collect dirt (which is an organic food source) due to their coefficient of friction (i.e. lower slip)—therefore, they offer a less-friendly environment for fungal growth.

These benefits, coupled with the freedom from roof penetrations that could potentially violate warranty, make standing seam metal roofs suitable not only for projects that need to be solar-ready, but buildings of all types.

Harry J. Lubitz, CSI, CDT, is the architectural and national accounts manager for S-5! Metal Roof Innovations Ltd. (Colorado Springs, Colorado). He works with the design community to develop and improve architectural specifications for metal roofs and attachment systems. Lubitz has more than 25 years of experience in the building materials industry, is active in numerous architectural and professional organizations including CSI, and has served as an adjunct faculty member at Lord Fairfax Community College in Virginia. He can be reached at hlubitz@S-5.com[14].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/bigstock-Solar-Panels-With-Technician-69565381.jpg

- ‘solar-ready’ assemblies : http://www.kenilworth.com/publications/cs/de/201106/56.html

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/PV_Figure1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/Figure-2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/Figure-3.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/Figure-41.jpg

- Survey results: http://www.rci-online.org/interface/2006-cts-cash.pdf

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/PV_Figure5.jpg

- Recent field studies: http://www.metalconstruction.org/index.php/education/tech_resources

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/PV_Figure6.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/11/PV_Figure7.jpg

- lower installed costs: http://www.constructionspecifier.com/quantifying-savings-with-infrared-reflective-metal-coatings

- heat-reflective capabilities: http://www.constructionspecifier.com/the-benefits-of-metal-roofs-and-coatings

- hlubitz@S-5.com: mailto:hlubitz@S-5.com

Source URL: https://www.constructionspecifier.com/planning-solar-ready-roof-advantages-with-standing-seam-metal-assemblies/