There are three crosslinking production methodologies for PEX (known as a, b, and c). PEXa is the most flexible, enabling the use of cold-expansion fittings as well as a tighter bend radius. Compared to insert fittings, cold-expansion fittings produce a more consistent connection due to the inherent shape memory of PEXa pipe.

To use cold-expansion fittings, an expander tool is placed inside the tubing to enlarge the PEX. The tool is turned multiple times until the tubing is expanded to the manufacturer’s specifications. With the ASTM F1960 design, the expanded tubing end is allowed to retract onto the fitting to form the seal with the aid of a ring. The connection is enhanced by the memory effect of the tubing, thereby not solely relying on the crimping mechanism for its security.

The latest generation of PEX fittings—cold-expansion with PEX compression sleeve—takes this connection security up a notch and speeds the formation of the connection by actively compressing a PEX sleeve over the expanded tubing and fitting.

Fixture flow rates of PEX and copper pipe were compared in a June 2008 study conducted by the National Association of Home Builders (NAHB) for the Plastics Pipe Institute (PPI).

It concluded, “PEX and copper piping systems will deliver sufficient volumetric flow rates to the plumbing fixtures when using the same nominal size tubing. While PEX tubing has a smaller inside diameter than copper tubing, both tubing systems meet the farthest fixture demand, even with multiple fixtures flowing,” (consult Fixture Flow Rate Comparison: Crosslinked Polyethylene [PEX] Piping and Copper Tubing [June 2008] by the National Association of Home Builders [NAHB] and PPI).

Over time, corrosion and other buildup can reduce the ID of copper pipe, thus reducing flow and pressure, and its effectiveness, in a commercial plumbing system.

Pipe sizing, layout options

When sizing pipe, a good practice is to look at the pressure loss tables of the manufacturer. One must not assume the PEX system should be upsized. Doing the math ensures the client is happier due to potential savings in material and energy costs.

The water supply fixture unit (WSFU) method helps determine the required load (gpm) and the resulting pipe size as defined by local governing plumbing code. Alternatively, particularly for larger buildings, the uniform friction head loss method can be used. It is also advisable to consider the maximum velocity of water flow. Once the flow rate is determined, the pipe can be sized based on the maximum allowable velocities, according to the prevailing local codes.

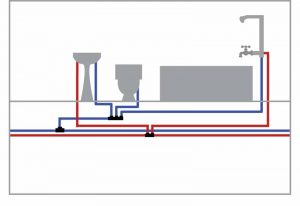

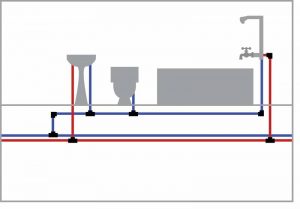

PEX has two piping layout options (tee and branch and remote multiport tee) while copper and CPVC have only one (tee and branch). A PEX tee-and-branch system uses the same layout as rigid pipe but with faster installation. When possible, installers should use bend supports instead of fittings to maximize the benefit of this method.

A remote multiport tee offers a variety of plumbing design possibilities due to the minimal amount of connections required. Fewer fittings means less leak potential and pressure loss as well as reduced installation time, which saves money for the building owner.

Codes and standards

All major model plumbing and building codes recognize PEX tubing as acceptable for water distribution piping.

Nationally accredited, third-party certification agencies, such as the International Code Council (ICC) and NSF International, require strenuous quality control (QC) testing, including random plant inspections and annual monitoring. Long-term hydrostatic pressure ratings as well as standardized chlorine resistance testing to ensure the piping will withstand the most aggressive drinking water conditions are also required.