Installation advantages

PEX tubing provides building owners reliability, durability, and cost savings, and makes plumbing installation easier and safer. CPVC plumbing systems require glue to join fittings. It is a time-consuming process, as the CPVC pipe ends must be primed, glued, and then held together while the adhesive dries.

Even more time-consuming is soldering and brazing, which is still used to install copper tubing. As this process requires a fire source, it can be a safety issue for the contractor and a liability for the building owner. Other methods to join copper are available, such as press-connect and push-connect fittings, both of which tend to be less reliable.

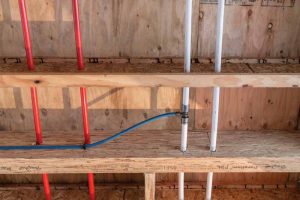

With PEX, installers have a flexible, easy-to-maneuver material requiring fewer fittings, which speeds up installation and reduces cost. A commercial installation time study performed by the Home Innovations Research Lab set up an experiment with two 15-year veterans of commercial plumbing in side-by-side timed installations of copper and PEX systems.

The study concluded the PEX plumbing systems installed up to 65 percent faster than copper systems. For plumbers, PEX won over copper installations because fewer fittings are needed and measuring, cutting, and attaching fittings to the pipe takes less time.

| CAN LEGIONNAIRES’ DISEASE BE MITIGATED? |

| Legionnaires’ disease is a severe form of pneumonia caused by the bacterium Legionella pneumophila. The Centers for Disease Control and Prevention (CDC) notes health professionals diagnosed almost 7500 cases in 2017, and the number of cases reported has been on the rise since 2000. The first case of the disease occurred in 1976 at an American Legion convention at a Philadelphia hotel. Of the more than 200 people who contracted the disease, 29 died.

While Legionella is found naturally in freshwater sources such as lakes and streams, most humans contract Legionnaires’ disease by inhaling contaminated water droplets, water vapor, steam, or mist. Legionella thrives in warm, stagnant water (20 to 50C [68 to 122 F]). Mitigating Legionella in plumbing systems requires maintaining sufficient hot-water temperatures and minimizing dead legs—the volume of water between either a hot water storage tank or a recirculation line and the fixture. CDC recommends maintaining hot water at the return at the highest temperature allowable by state regulations or codes, preferably greater than 51 C (124 F), while using preset thermostatic valves in point-of-use fixtures to help minimize the risk of scalding. Similarly, the Occupational Safety and Health Administration (OSHA) recommends maintaining water heaters at 60 C (140 F) and delivering hot water to all outlets at a minimum of 50 C (122 F). Further recommendations include frequently flushing lines, especially dead legs, and running hot water recirculation pumps continuously to avoid stagnation. A hot water recirculation system can help control Legionella growth by circulating hot water at regular intervals throughout the plumbing system. These systems were initially designed to conserve water by reducing hot water wait times for occupants. However, a drawback of these systems is that continuous recirculation may consume unnecessary amounts of energy, particularly during the times of day when a building is unoccupied. To address this trade-off between water and energy waste, the plumbing industry has introduced controls such as timers, aquastat controls, and occupant sensors. Use of these controls in hot water recirculation systems is required by current model plumbing codes. |

Conclusion

A versatile material, PEX is suitable for commercial plumbing applications because it is flexible, reliable, and durable. The pliable nature of PEX allows contractors to bend and position the tubing where needed, requiring fewer fittings than rigid piping systems, thereby reducing installation time and saving building owners money.

Cold-expansion fittings help enlarge the ID of PEX tubing while providing a tight seal and virtually leak-proof connection. Further, PEX does not corrode or degrade like metal plumbing systems and, therefore, assures longevity.

Given the data and conclusions from industry sources and experience from installers, there is evidence to consider the advantages of specifying PEX in commercial plumbing projects.

David Nickelson is a technical team leader in the building solutions division at REHAU’s North American headquarters in Leesburg, Virginia. His responsibilities include product development, codes and certifications, industry standardization work, and crosslinked polyethylene (PEX) production support. Nickelson is the secretary of ASTM F17.10 subcommittee and represents REHAU on all voting matters in standards development organizations such as ASTM, NSF International, the Canadian Standards Association (CSA), Underwriters Laboratories (UL), and the National Fire Protection Association (NFPA). Nickelson is also the chair of Plastics Pipe Institute’s (PPI’s) technical committee. He received a bachelor’s degree in mechanical engineering from Pensacola Christian College. He can be reached at david.nickelson@rehau.com.

Jon Bittenbender is the director of engineering for the building solutions division of REHAU. He has been involved in the engineering of the company’s PEX-based applications, including plumbing, radiant heating and cooling, hydronic piping, turf conditioning, and snow- and ice-melting since 1999. Bittenbender holds a bachelor’s degree in mechanical engineering from the Pennsylvania State University. He can be reached at jonathan.bittenbender@rehau.com.