Power-operated doors: Maintaining safe egress with updated standards

by carly_mchugh | June 17, 2022 7:38 pm

HORIZONS

HORIZONS

Michael Tierney

The safe and practical use of electric locking systems, accessibility, touchless entry, and an immediate unencumbered means of egress are among the reasons to select a power-operated door within the envelope of a public building. Power-operated doors are available in a wide variety of designs and styles to fulfill the requirements of the building envelope and interior.

Qualities to consider when specifying a power-operated door include reliability, safe egress, accessibility, energy conservation, security, and aesthetics. The Builders Hardware Manufacturers Association (BHMA) is the American National Standards Institute (ANSI) accredited developer for power-operated door and hardware standards. The association has published four different standards to cover the breadth of power-operated door products:

- ANSI/BHMA A156.10: Power-Operated Pedestrian Doors

- ANSI/BHMA A156.19: Power Assist and Low Energy Power-Operated Swinging Doors

- ANSI/BHMA A156.27: Manual and Power-Operated Revolving Doors

- ANSI/BHMA A156.38: Low Energy Power-Operated Sliding and Folding Doors

Every standard follows a set schedule for periodic review, to reassess and improve the content and requirements. ANSI/BHMA A156.10 was revised in 2017, and the remaining three standards were revised in 2019.

[1]

[1]Power-operated pedestrian doors

ANSI/BHMA A156.10 covers power-operated doors intended for regular pedestrian use. The function of these doors imply they will open automatically when approached by pedestrians and, in some cases, small vehicles. These include swinging doors, sliding doors, and folding doors with accessories such as guide rails, motion detectors, knowing act door activation devices (e.g. an automatic door push button), control mats, and presence sensor monitors.

Entrapment protection for user safety is another important aspect of this standard. This section of ANSI/BHMA 156.10 is intended to reduce the chances of an automatic door closing on an object or person. Entrapment protection varies depending on the type of door. Sliding doors require a specific closing speed at which the kinetic energy is calculated using the weight of the door, and the closing latch check can be no less than 50.8 mm (2 in.) from the door being completely closed.

Other entrapment protection specifications for sliding doors can include a breakaway device, as well as a specific amount of time the door must remain fully open before closing. For swinging and folding doors, entrapment protection includes backchecks; opening and closing times depending on angles, distance, and weight; hinge opening size to minimize pinch points; and the minimum force required to stop or manually open the automatic doors.

Aside from entrapment protection, there are also breakaway egress tests, including salt spray and cycle tests. For the salt spray test, a sample of the hardware is subjected to salt fog for 168 hours to ensure the finish and critical parts of the assembly are resistant to corrosion and retain their functionality. The cycle test is done with the largest specimen listed by the manufacturer. It must undergo 300,000 cycles at a rate of five to eight per minute—with 1,000 breakout cycles every 50,000 cycles—and utilize unadjusted breakaway devices.

Knowing act activation references the action of triggering a mechanism for a door operator, such as pressing a switch with the knowledge it will open the door in connection with said switch. Knowing act specifications within this standard for each door type indicate the triggering mechanism must:

- Be within view of the automatic door.

- Have a height between 0.9 and 1.2 m (3 and 4 ft).

- Remain accessible from the swing, slide, or fold side when the door is opened.

- Not be located in a position where the user would be in the path of the moving door.

- Keep the door fully open for a minimum time delay of five seconds after release of the triggering mechanism, or longer depending on the distance from the device to the center of the door.

- Be equipped with safety zones, monitoring, time delays, and guide rails as required for the type of door.

Further requirements are outlined by door type, and alternative guidelines are set for double-egress doors.

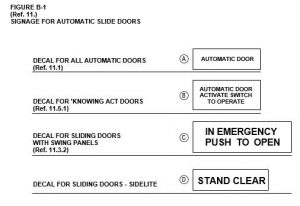

Signage is also an important component for automatic doors. ANSI/BHMA 156.10 indicates the necessary font, color, size, and visibility for various power-operated pedestrian doors. For example, all swinging, sliding, and folding doors shall be equipped with “Automatic Door” signage visible from both sides, with letters a minimum of 12.7 mm (0.5 in.) high. Other signage includes “In Emergency Push to Open,” “Caution Automatic Door,” “Do Not Enter,” and directional arrows depending on the door type.

ANSI/BHMA 156.10 neither accounts for low-energy power-operated doors, nor includes fire exits and emergency doors. Additional specifications for this standard include control mat layouts, sensor zones, guide rail details, and further knowing act door activation device installation requirements.

[2]

[2]Power assist and low-energy power-operated swinging doors

A low-energy power-operated door is activated only by a knowing act, adheres to the maximum amount of kinetic energy allowed by ANSI/BHMA A156.19, and is closed by a power mechanism or other means. These doors are intended to improve accessibility. The Americans with Disabilities Act (ADA) requires hardware to comply with ANSI/BHMA A156.19 if a building utilizes power assist and low-energy power-operated swinging doors. The most recent publication of this standard includes a revised definition of “knowing act,” to incorporate methods such as cell phone apps.

Unlike ANSI/BHMA 156.10, ANSI/BHMA A156.19 addresses power assist and low-energy power-operated doors, but only for automatic swinging doors. The swinging door operators in this standard are for pedestrian use and some small vehicular use.

Power assist doors can be operated by pushing or pulling the door, and a separate switch is permitted to put the door in power assist mode. A minimum time delay of five seconds is required, there is a minimum number of seconds for a door’s closing time, and a maximum force is required to stop and manually open a door.

Low-energy power-operated swinging doors also require a knowing act, usually by a wall-mounted switch. The switch location of the knowing act has been adjusted in the most recent publication. If the activating mechanism is located 2.1 m (7 ft) or more from the center of the door, there shall be an additional time delay of two seconds for each additional foot. Opening shall take three seconds or longer to reach either an 80-degree angle or backcheck, and backcheck cannot occur before a 60-degree angle. This section of the standard mandates a time delay where the door is fully open for no less than five seconds unless push-pull activation is used, which is a minimum of three seconds. Other guidelines for low-energy power-operated swinging doors include closing and the maximum force for closing prevention and manual opening.

[3]

[3]ANSI/BHMA A156.19 requires a 300,000-cycle test with speed checks and specific signage. Power assist doors feature signage with “Easy Open Door,” followed by the proper action for operation. Aside from “Caution Automatic Door,” low-energy power-operated swinging doors must include knowing act signage. This signage reads “Activate Switch to Operate,” “Push to Operate,” or “Pull to Operate.”

This standard does not regulate doors, finish, or hardware, nor doors which require higher speeds, forces, shorter time delays, or activating sensing devices. Moreover, each door activation described for power assist and low-energy power-operated swinging doors requires a knowing act. Revisions to the prior version of this standard include additional details to the knowing act information—which can similarly be found in ANSI/BHMA 156.10. The intent of this standard is to best prevent injury and entrapment for users.

Power and manual-operated revolving pedestrian doors

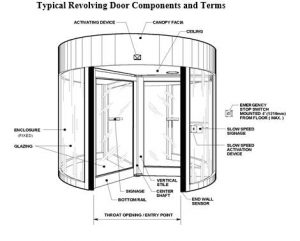

ANSI/BHMA A156.27 primarily focuses on manual revolving doors for pedestrian use and power-operated revolving doors, which rotate automatically when approached by pedestrians and some small vehicles. This standard also covers automatic revolving doors with a center shaft, automatic revolving doors with a core, automatic two-wing revolving doors, access-controlled revolving doors, and access-controlled revolving doors with one-way free passage. The included criteria are provisions to reduce the chance of user injury and entrapment.

Each door type within this standard provides regulatory information for enclosure size, door speed, egress, signage, glazing, clearances, obstruction force, slow speed operation, sensors, guard sensors, kinetic energy, position, activation, presence sensor monitoring, and break out force requirements. Egress requirements for revolving doors must include an egress path a minimum of 0.9 m wide.

Additional topics covered in this standard include glazing and emergency stop switches. Revolving doors for industrial or trained traffic are not covered, and this standard does not attempt to assess any existing factors with respect to custom installations.

[4]

[4]Low-energy power-operated sliding and folding doors

While similar to ANSI/BHMA A156.19, ANSI/BHMA A156.38 covers sliding doors as opposed to swinging doors. As with the other standard, this standard is for pedestrian use and some small vehicular use, and the activation of all doors described in this standard requires a knowing act.

Requirements include the 300,000-cycle durability test and mandates for specific signage specifications dependent on varying factors. Signage involved with this standard includes the familiar “Automatic Door,” “Activate Switch to Operate,” and the recently updated “Slide to Operate.” Intentions for this standard are based on the desire to promote safety when using low-energy power-operated sliding doors.

Low-energy power-operated sliding doors comply with this standard if they open at a maximum speed of 304.8 mm (12 in.) per second, close at a maximum speed of 152.4 mm (6 in.) per second, and remain open for a minimum of five seconds before beginning the closing cycle. Low-energy power-operated folding doors shall open to 90 degrees in a minimum of 4.5 seconds and remain open for no less than five seconds before initiating the closing cycle. Unless provided with a finger guard, these doors require a specific clearance. The opening at the hinge side of the folding door can be less than 6.35 mm (0.25 in.) or a minimum of 19.05 mm (0.75 in.) wide with the door in any position.

[5]

[5]Knowing act requirements and switch location have been revised for ANSI/BHMA A156.38. This standard does not assess any existing factors with respect to custom design installations. Doors requiring higher speeds, forces, shorter time delays, and activating sensing devices are also not covered and, as appropriate, shall comply with ANSI/BHMA A156.10.

Conclusion

All four of these standards regarding power-operated doors have been adopted by the International Building Code (IBC) and the National Fire Protection Life Safety Code (NFPA 101). All four standards combined aggregate various safety means and implications. Each standard, though similar in content coverage and topic, grasps a deep understanding of the needs for public power-operated doors, and the importance of accessibility and safe egress. Additional information can be found by referencing the full individual standards and one-page Hardware Highlights offered on the BHMA website[6].

For more than 19 years, Michael Tierney has served as the product standards coordinator for the Builders Hardware Manufacturers Association (BHMA), where he coordinates the development and revision of BHMA’s performance standards for building hardware products. Tierney came to BHMA following a 20-year career in manufacturing management at United Technologies, Honeywell, Black and Decker, and Yale Security. He is a principal member on technical committees for the National Fire Protection Association; the A117 Committee for Accessible Buildings, and the American Society for Testing and Materials (ASTM). He is also chair of the ANSI TAG 162 for Doors and Hardware.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/12/Doors-F-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/12/Figure-B1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/12/Figure-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/12/Figure-3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/12/Figure-4.jpg

- BHMA website: https://buildershardware.com/

Source URL: https://www.constructionspecifier.com/power-operated-doors-maintaining-safe-egress-with-updated-standards/