Preliminary selection of exterior waterproofing systems 2021

by maz_atta | June 30, 2021 12:00 pm

Los Angeles Chapter of Construction Specifications Institute Technical Committee

[1]

[1]Selection of suitable waterproofing systems can present building project teams with a baffling array of choices. With hundreds of products to choose from, there is a formidable QUANTITY of data to evaluate to make a thorough investigation. Unfortunately, there did not appear to be a standard methodology for making product selections, which is especially daunting for THOSE with limited personal experience. Even seasoned professionals can be stymied when confronted with unusual project conditions.

To address this concern in 2002, the technical committee of the Los Angeles Chapter of the Construction Specifications Institute (LA-CSI) developed a guide to ‘Preliminary Selection of Waterproofing Systems.’

“Our goal was to help the design team make better waterproofing decisions more efficiently,” said Roger A. Cormier, CSI, CCS, who was committee chair at that time. waterproofing was defined in MasterFormat (1995 ed.) as: “Impervious, waterproofing membranes, coatings, and other materials applied to walls, slabs, decks, and other surfaces subject to continuous and intermittent hydrostatic pressure or water immersion.”

The committee’s report was published in The Construction Specifier (August 2002) and in industry newsletters; its widespread circulation indicates it satisfied an important need.

“During two decades since then, there have been numerous changes in waterproofing technology, conditions of use, MasterFormat (2020 ed.), and industry best practices,” said Melisa Sharpe, Architect, CSI, CDT, DBIA, LEED-AP, and current chair of the LA-CSI Technical Committee.

“The technical committee of LA-CSI took this into consideration and revised the document to make it easier to make preliminary product selection decisions about waterproofing systems and to find products that address the project needs.”

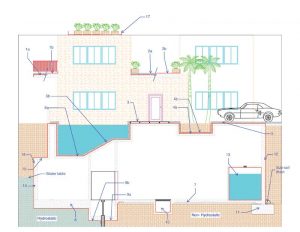

The new guide includes a diagram of a structure with typical waterproofing applications. These applications are referenced to a waterproofing application matrix (see page 18) that identifies which types of waterproofing system technologies (along with the MasterFormat section names and numbers in which these materials are typically specified) are generally suitable for application.

Limitations

[2]

[2]The diagram and matrix are a useful guide but should not be used as a ‘cookbook’ for comprehensive specification of waterproofing.

Material manufacturer technical representatives, waterproofing consultants, experienced colleagues, and specialty installers can help ‘tailor’ a system to project conditions and assess risks, pitfalls, and reasonable performance expectations. Everyone has their own experience with and biases about waterproofing, and it can be useful to consult multiple parties to obtain a range of options and their pros and cons for a given installation.

Detailing

Manufacturers generally have details, specifications, and installation instructions that define recommendations for their own products. The information, not surprisingly, shows only conditions that are within a proprietary system or terminates generically to adjacent products. Specifications need to discuss interfaces with other waterproofing products, water-resistive barriers, and other systems.

Quality

[3]

[3]Performance of waterproofing is limited by the skill and care of its installer. Therefore, specifications should include requirements of the manufacturer and installer qualifications, plus other measures to ensure quality. Helpful documents include shop and installation drawings, mockups, field testing, and observations. Some manufacturers require part- to full-time monitoring of installation as a condition of warranty. manufacturer technical representatives may be able to provide adequate field oversight; otherwise, it may be advisable to retain third-party consultants or inspectors to check work in progress.

Additional considerations

Waterproofing is subject to the environmental conditions of the site, applicable building codes, and the building conditions it is intended to protect. Typical site and building conditions for a specifier to consider are:

Site soil and water table

[4]

[4]Will the ground have hydrostatic conditions? Will there be soil or groundwater conditions that are deleterious to waterproofing? How does the structure resist hydrostatic loading? Vapor barriers can be used in non-hydrostatic conditions to prevent water vapor migration from damaging impermeable floor finishes, but should not be used in hydrostatic conditions. Typically, hydrostatic grade waterproofing also functions as a vapor barrier.

Shoring

Many projects require perimeter shoring, such as steel wide-flange soldier beams with treated wood lagging. Tiebacks or rakers used to resist loading from the adjacent soil may have to be removed during later stages of construction; this requires out-of-sequence patching of waterproofing and needs to be addressed.

Waterproofed surfaces

Each structural material has characteristics that affect waterproofing design. Shotcrete, for example, has a tendency for voids and slump to form during placement. The unique challenges of each substrate should be considered and mitigating measures specified.

Drainage

Non-hydrostatic walls usually have drainage to a base-of-wall collection system that conveys water away to a sump or storm sewer. The drainage must be designed to accommodate expected site drainage in service. Misdirected surface water or unexpected ‘perched’ below-grade water can increase demand on drainage capacity. The waterproofing specifier may have to remind the design team of the need for adequate drainage for proper waterproofing performance.

Damage during construction

Waterproofing is generally installed early in a project schedule and may remain exposed for weeks or months. On horizontal surfaces, it may even be used as a work platform. consider means to protect and repair waterproofing until it is properly covered.

Post-construction repairs and supplemental waterproofing

grout injection can be used to repair leaks in below-grade concrete and to help conditions not easily waterproofed by other means. Crystalline coatings or slurries can be used to repair seepage and dampness on the ‘negative side’ of the structure, or as a supplement to waterproofing on the ‘positive’ side of the structure.

Summary

[5]

[5]Other factors affecting waterproofing are beyond the scope of the guide.

Once a broad category of product is selected, performance and product variables such as application thickness, availability of materials and labor, costs, warranty provisions, environmental factors, project limitations, and other factors must be considered to refine one’s options within the category. Moreover, the guide does not address damp-proofing, water repellents, or roofing—processes sometimes grouped inappropriately with waterproofing.

Guide users must read manufacturers’ literature, industry reference materials, and codes to evaluate proposed materials for a specific application. When necessary, advice should be obtained from trusted manufacturer representatives or qualified consultants. Information from independent testing facilities should be considered and, if necessary, tests can be performed on a mock-up to demonstrate the effectiveness of a product in a particular application.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/AVM560-underslab.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/DTR-071416-Cold-Fluid-Applied-Waterproofing-drain-matDTR.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/SHG-IMG_3305.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/Table-2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/Building-Sketch_2.jpg

Source URL: https://www.constructionspecifier.com/preliminary-selection-of-exterior-waterproofing-systems-2021/