Testing approach

This study characterized joint infiltration as a function of construction quality as well as environmental factors. The impact of construction was assessed as a function of joint cleanliness, sealant damage, joint movement, and sealant type, and the environmental factor as the predicted infiltration resulting from rainfall intensity, joint geometry, and cross slope.

Three sealant types were evaluated: silicone, hot pour, and compression seals. The impact of joint infiltration on pavement performance was determined by conducting laboratory tests to quantify subbase erosion, and by developing a predictive model and supporting software. With these tools, an owner can determine the impact of sealing joints, as well as joint conditions on pavement performance. Another aspect of the study evaluated the use of ground-penetrating radar (GPR) to detect the existence of moisture under the slabs in the vicinity of the joint.

One age-old question on this matter is: ‘When is it all right to reseal?’ This was resolved by applying weighting factors to a sealant condition, such as amount of adhesive and cohesive failure, missing sealant, etc. However, none of these surrogates addresses fundamental properties related to actual performance. With the use of GPR, it seems feasible to detect the existence of moisture under the slabs in the vicinity of the joint—from a water infiltration standpoint—and more importantly, to assess when a sealant is no longer effective.

Onsite testing

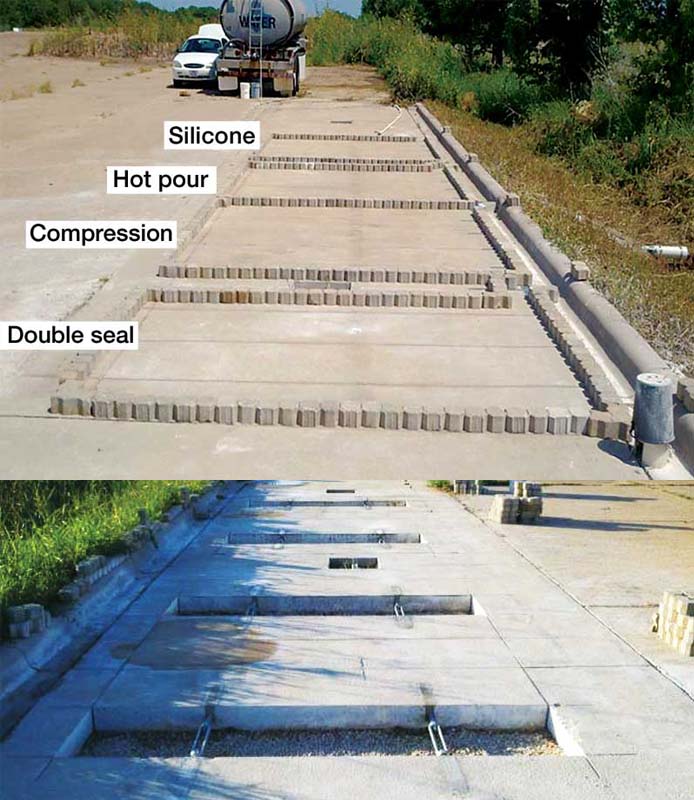

The study consisted of both controlled field experiments and testing of in-service pavements. The former were conducted at TTI’s Riverside Campus (Figure 1), and designed to evaluate the effects of sealant damage and joint cleanliness on infiltration rates. After the first round of testing was conducted using this setup, a unique approach was developed. This approach allowed the width of the joint opening to be varied, then taken into account along with the joint seal damage.

Testing of in-service pavements occurred on Route 59 (Plainfield, Illinois), and on I-10, just west of Phoenix, Arizona. The purpose of testing in-service pavements was to relate sealant effectiveness (i.e. infiltration rates) to actual pavement performance. The Plainfield project was approximately four years old and consisted of 10 test sections, including sealed and unsealed joints. The Phoenix project was a federally-funded, Long-term Pavement Performance (LTPP) Specific Pavement Study focused on Rigid Pavement (SPS-2), which was 20 years old and consisted of 20 test sections, including four different base types. The procedure consisted of conducting infiltration and falling weight deflectometer (FWD) testing (Figure 2).

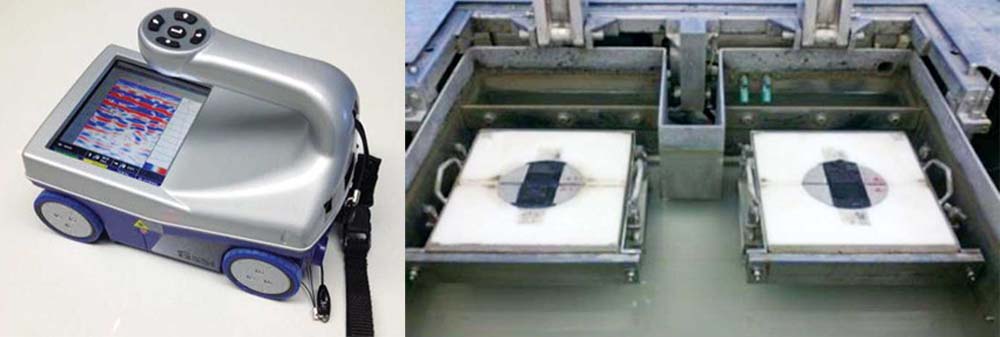

Limited GPR testing was also conducted at each of the sites to evaluate the potential for using GPR to detect when the sealant was allowing water infiltration into the joint. A handheld, portable GPR unit was used for this testing (Figure 3). Subbase samples were also retrieved through core holes in the pavement to enable laboratory erosion testing using a Hamburg wheel tracking device (HWTD).

The HWTD test consisted of two component layers: a concrete cap on top, with another layer placed immediately under it. As a wheel passed on top of the two layers, the sensors recorded the deflection for each pass. The testing was conducted under wet conditions, in which erosion normally occurs due to mechanical and hydraulic shearing on the subbase layer generated by slab movement under an applied load. Erosion resistance (ER) is defined as the amount of erosion at 1,000,000 load applications under HWTD erosion testing. A greater ER indicates a subbase or subgrade material has less resistance against erosion.

Interesting share, excellent understanding. Very nice blog about concrete pavement I’m pleased through the info.