Protecting those inside: Specifying blast hazard-mitigating windows

by Katie Daniel | October 30, 2015 11:35 am

[1]

[1]by Tom Mifflin

Exposed to the extreme pressure released by an explosive mass, elements of the window or curtain wall assembly work together to withstand the blast load and dissipate its energy. Laminated glass takes the brunt of the blast force, the framing connections and glass bites work together to keep the lites in their frames, the mullions and sashes adequately deflect to handle the assembly’s changing shape, and window hardware transfers load to perimeter framing.

As the blast load is transferred from exterior to interior, the window or curtain wall anchorage must help ensure the most comprehensive protection. Flexibility is key—too many anchors make the assembly overly stiff, and add unnecessary time and cost to the installation schedule. The type and number of anchors depend primarily on the substrate and its robustness. Ultimately, residual blast energy is imparted to the building structure itself.

Understanding how these assemblies work is critical for specifiers and design professionals working on high-profile architectural structures and iconic destinations, along with high-value institutions, such as banking and financial centers, transportation networks, utilities, water supply systems, and emergency and medical facilities. However, it is also especially important for public-sector projects.

In a response to the terrorist attacks of the past 20 years, security policies at all levels of government have been developed and continue to be updated. These policies enhance protection in not just owner-occupied facilities, but also in domestic real estate leased by federal, state, and local governments, as well as U.S. military services and the intelligence community, law enforcement, fire, rescue, and first responders.

[2]

[2]Windows for military facilities

Blast hazard mitigation requirements for planning, design, construction, and modernization of many U.S. military facilities are defined in the Department of Defense (DoD) Unified Facilities Criteria (UFC)[3] 4-010-01, “Minimum Anti-terrorism Standards for Buildings,” 9 February 2012, Change 1, 1 October 2013 (referred to hereinafter as UFC 2013). They can include barracks and billeting, family housing, office structures, armories, readiness centers, and child development centers (on and off military bases).

UFC 2013 Appendix B Standard 10 covers windows, curtain walls, and skylights. Requirements in previous versions of this standard were generally based on capacity of wall construction for “conventional construction standoff distance,” and allowed pre-engineered designs to comply based on limited analysis and even standard product testing.

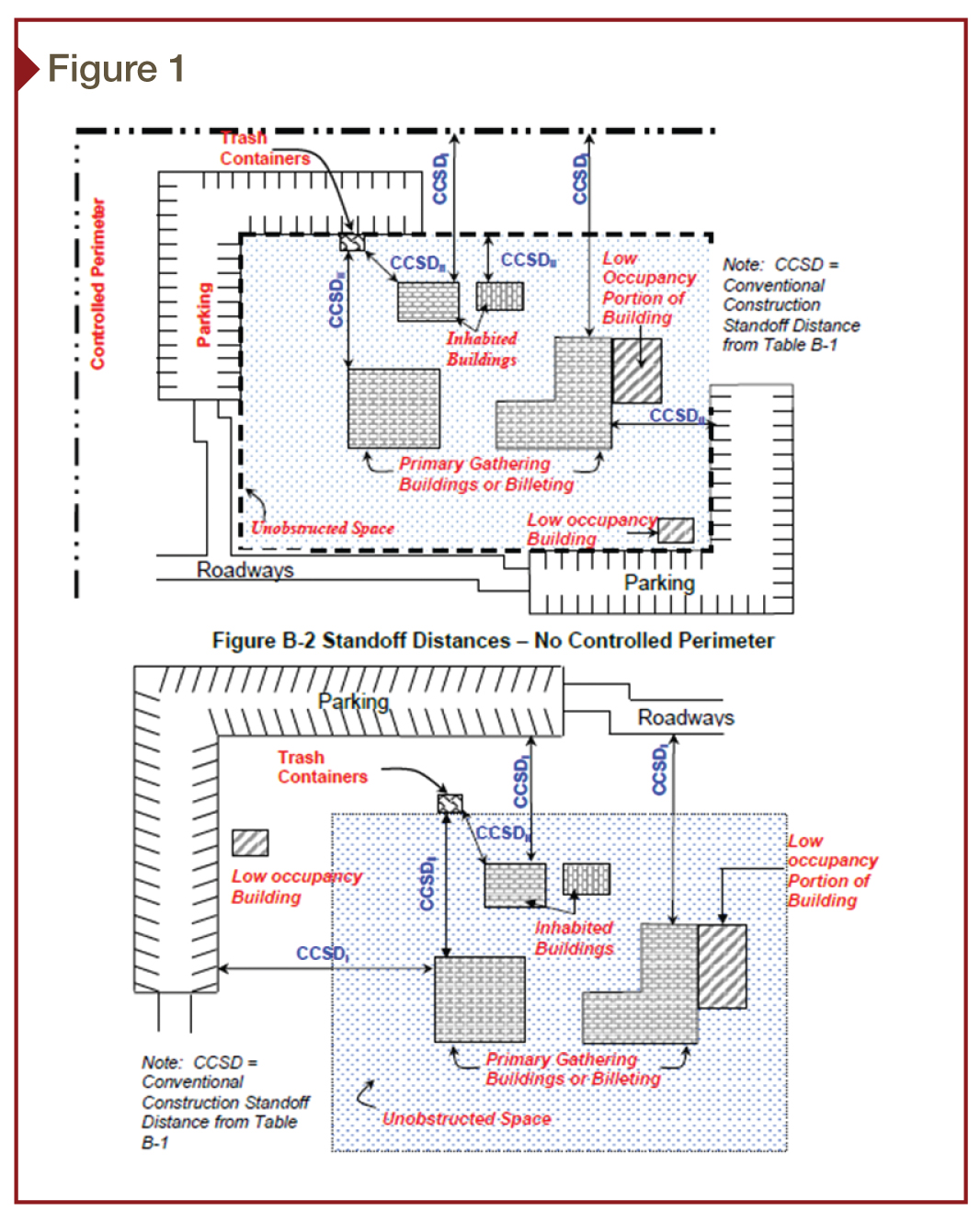

The UFC 2013 standard requires window and curtain wall designers and specifiers to consider certain parameters of the specific building’s threat assessment—standoff distance and charge weight—as well as protection level. In simple terms, design must be based on the project-specific site plan, perimeter control fences, and checkpoints shown schematically in Figure 1, as well as acceptable intrusion of glazing fragments into perimeter areas of the occupied space. Unlike previous versions, one-size-fits-all pre-tested, standard blast windows seldom meet UFC 2013 requirements.

The current version of the standard allows for value-engineering of blast hazard-mitigating windows and curtain wall in the same project, based on exposure. Relative to fenestration, UFC 2013 provides the following rationale for changes to the standard:

– To reduce misunderstandings of some of its provisions.

– To address situations not previously addressed by the standards.

– To improve consistency of interpretation.

– To reduce redundancy or inconsistency with other UFCs that were not available at the time of the previous revision.

– To eliminate standards or recommendations that were unnecessary or that had been superseded by other UFCs.

– To incorporate information based on new studies and research or new or revised national standards.

– Reduced costs of window systems and of supporting structural elements due to changes in Standard 10 on windows and skylights.

– Added warnings throughout the document that for some wall types the conventional construction standoff distances will require window and door construction that is significantly heavier and more expensive than windows and doors designed at the conventional construction standoff distances in previous versions of these standards.

In general, many windows tested to previous versions of the standard have been found to be adequate when project-specific standoff distance is greater than 13.1 m (43 ft) for Charge Weight I, or 7 m (23 ft) for Charge Weight II for a “Low” level of protection. For any given project, these generalizations may or may not apply. Design parameters for peak pressure in kPa (psi) and impulse in kPa.msec (psi.msec) vary widely between projects and even between elevations within a building.

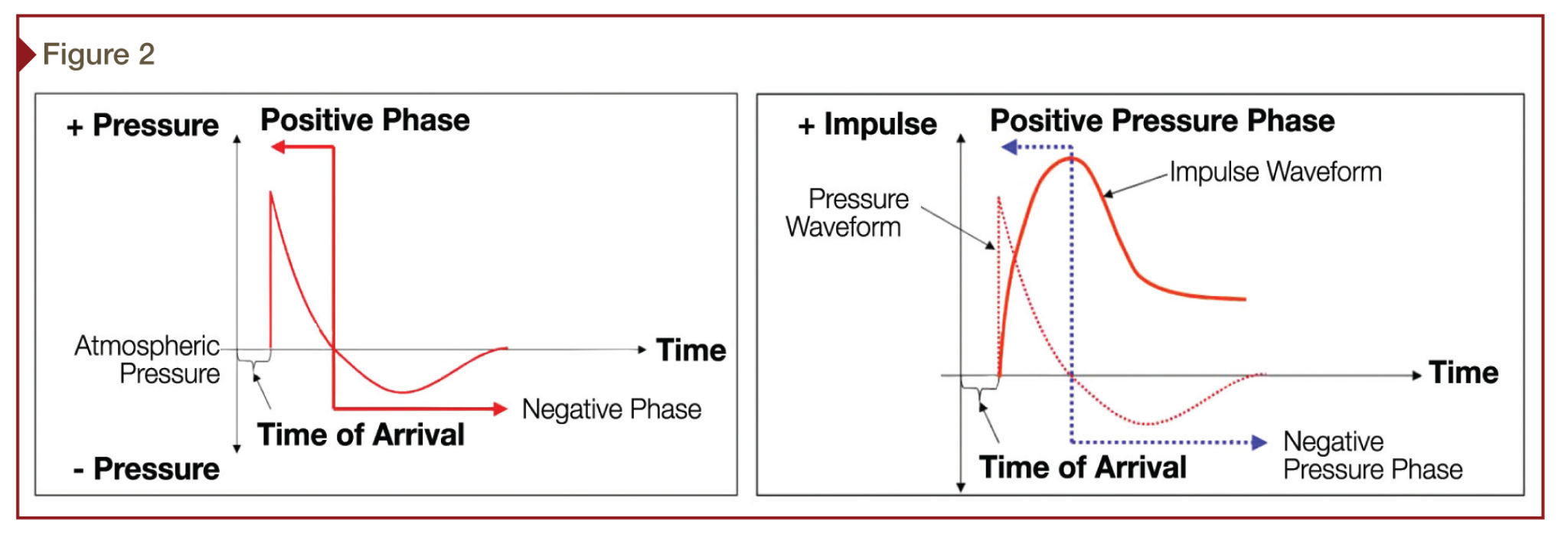

As shown in Figure 2, peak positive pressure occurs almost instantaneously after the arrival of the shockwave, dissipating in milliseconds to the negative phase rebound load. The area under the positive pressure-time curve is defined as the positive phase impulse—a measure of the blast energy imparted to the glazing.

[4]

[4] [5]

[5]The right glass for the project

In the current UFC 2013, ASTM F2248, Standard Practice for Specifying an Equivalent Three-second Duration Design Loading for Blast-resistant Glazing Fabricated with Laminated Glass, is applied to the level of protection, explosive charge weight, and standoff distance to arrive at an equivalent three-second-duration design loading. In turn, this equivalent load is used to select the glass make-up. Protective Design Center (PDC) Technical Report 10-02 should be referenced for charge weights and standoffs beyond the ranges of ASTM F 2248 and ASTM E1300, Standard Practice for Determining Load Resistance of Glass in Buildings.

Other ASTM standards are referenced within ASTM F2248 to help ensure consideration of all factors affecting glass selection. In many cases, key factors affecting glass selection are not all blast-related, and may include:

- size or aspect ratio constraints in glass fabrication;

- aesthetic considerations such as flatness or available coatings;

- energy efficiency;

- acoustic performance; or

- resistance to wind loading.

The glass makeup resulting from application of these selection criteria can be stronger and stiffer than the minimum acceptable glass makeup prescribed by ASTM F2248 or commonly used software based on the criteria outlined therein. Stronger, stiffer glass can have a significant effect on structural design of the window framing used to support it, as detailed in the following paragraphs. It is vital framing design be based on the glass makeup actually being employed—not on the minimum acceptable makeup meeting blast hazard mitigation requirements.

[6]

[6]Glass support must comply with glass bite or structural silicone joint width requirements of ASTM F2248. For structural silicone glazed systems, joint width must be equal to the larger of 9.5 mm (3⁄8 in.) or the thickness of glass to which it is adhered, but not larger than two times the thickness of the glass to which it is adhered. The minimum allowable thickness of the joint is 4.8 mm (3⁄16 in.).

For monolithic laminated glass, structural silicone must be applied to both faces, while for insulating glass units (IGUs) with laminated glass as an inner ply, structural silicone shall be applied to the inboard face. With systems that do not utilize structural silicone, the window framing must provide glass bite equal to two times but no more than four times the thickness of glass to which it is adhered.

Dynamic analysis can be provided, indicating adequacy of the glass bite across the full range of unit size variation. The analysis has been validated by shock-tube and open-arena testing at laboratories accredited specifically for blast testing.

UFC 2013 (as well as all previous versions of the standard) indicates a clear preference for blast hazard-mitigating window and skylight assemblies that incorporate laminated glass or polycarbonate as an interior layer. Section 2-4.15 “Alternate Window Treatments” states in part:

Standard 10 does not allow for the use of window treatments such as fragment retention films and blast curtains where buildings are required to meet these standards. The primary reason for that is the fact that such solutions commonly have much shorter design lives than laminated glass windows, which requires their replacement multiple times as compared to laminated glass windows. Laminated glass, while more expensive initially, is less expensive over its lifecycle.

[7]

[7]Window framing

Framing members are then designed with deflection not to exceed 1⁄60th of unsupported spans at a load equivalent to two times the glazing resistance determined by ASTM F2248, and connections and anchors sized to absorb and transfer this load to the building structure. Calculations use allowable stress or strength design methods similar to conventional design for wind load.

As potentially less-conservative alternatives to the simplified equivalent three-second-duration design loading, or for higher levels of protection, UFC 2013 allows dynamic analysis using computer finite element modeling to predict how the total assembly will respond. Dynamic analysis offers a significant opportunity to optimize design through fine-tuning system parameters to meet the needs of a specific project—saving material, minimizing fabrication costs, and facilitating easy installation. Testing of representative mockups is also allowed.

Determination of applicable level of protection, standoff distance, and charge weight is the responsibility of the owner’s security/blast consultant/architect; and not that of the window manufacturer or installer. Given these parameters, all calculations should be prepared by a registered professional engineer directly contracted by, or in the employ of, the manufacturer or glazing subcontractor.

It is imperative calculations address specific project requirements, including all framing materials to be furnished. Calculations from other projects, non-representative test results on other systems, or other qualitative analysis generally are unacceptable as a substitute for project-specific calculations.

While project-specific calculations indicating adequacy of framing connections and anchorage must be provided, static analysis of dry-glazed systems is inadvisable. All frame-to-frame connections and connections to the building must be designed using ASTM F2248 under the assumption the glazing fails before the frame members and their connections. To ensure this, connections must be designed to two times the glass load resistance if the maximum air-blast pressure is greater than half the glass load resistance. If pressure is less than half the glass load resistance, connections must be designed to two times the glass load resistance.

Allowable stresses are published by the Aluminum Association, American Institute of Steel Construction (AISC), Allied Construction Industries, or American Iron and Steel Institute (AISI) for the respective materials used in each component. Geometry and connection configuration must be taken into account when calculating loads on connections and anchors.

In addition to blast loads, all components must be designed to satisfy applicable code requirements for adequate glass support, wind, and gravity loads.

Testing

Shock-tube or open-arena testing at a laboratory specifically accredited for blast testing may be acceptable in lieu of static or dynamic analysis, if sizes and configurations tested comply fully with the limitations of U.S. Army Corps of Engineers/U.S. Naval Facilities Engineering Command/Air Force Civil Engineer Center/National Aeronautics and Space Administration (USACE/NAVFAC/AFCEC/NASA) Unified Facilities Guide Specification (UFGS). This specification cites ASTM F1642, Standard Test Method for Glazing and Glazing Systems Subject to Air-blast Loadings, as the basis for alternative compliance.

It is vital to realize UFGS allows only relatively minor departures in size and configuration between tested windows and those to be used for any given project, which can be 25 percent smaller or 10 percent larger in area than the test specimens. ASTM F1642 requires a minimum of three specimens for each pressure and impulse combination. One should be skeptical of claims ‘standard’ windows have been pre-tested to meet specific project requirements.

Energy matters

Like other federal agencies, DoD and design teams working on military buildings of all kinds are committed to complying with high-performance building laws and executive orders. As noted in the National Academies’ “Energy-Efficiency Standards and Green Building Certification Systems Used by the Department of Defense for Military Construction and Major Renovations[8]:”

Specifically, DOD’s policy is that all new building design and construction and all major renovation projects should conform to the Guiding Principles for Federal Leadership in High Performance and Sustainable Buildings (as outlined in Executive Order 13423) and must meet a LEED-Silver rating or equal at a minimum. Beginning in fiscal year (FY) 2012 for projects in the planning stage, the sum of energy and water efficiency credits must equal or exceed 40 percent of the points required for a LEED Silver or equivalent rating.

Blast hazard mitigation requires no compromise in energy-efficiency goals. Manufacturers offer designs that employ sustainable features such as:

- operable vents—both outward-projecting and inward-projecting—for natural ventilation;

- large daylight openings for views, a connection to the outdoors, and natural daylight-harvest using dimmable artificial lighting; and

- spectrally selective, low-emissivity (low-e) coatings on triple-insulating glass for low thermal transmittance (U-factor) and low solar heat gain coefficient (SHGC).

The mandated project-specific design provisions of the new UFC 2013 are especially conducive to optimization of framing and glass selection to suit the sustainable design needs of specific sites, building orientation, and programmatic needs.

[9]

[9]Protection starts with specifications

UFGS provides templates for specifiers working on DoD projects, both new construction and major renovations. Section 08 51 13 (“Aluminum Windows”) is applicable to one type of blast hazard-mitigating fenestration product, and is employed as an illustrative example herein. UFGS is developed and prepared per criteria and standards established in UFC 1-300-02 “UFGS Format Standard,” dated 1 April 2014.

In addition to non-blast-related specification criteria, UFGS Section 08 51 13 includes minimum antiterrorism performance requirements, validated by one of three methods:

- static equivalent design approach;

- alternative dynamic method of design; or

- shock-tube or open-arena testing per ASTM F1642 at a laboratory accredited specifically for blast testing.

While minimum loading parameters for air-blast testing are provided in UFGS Section 08 53 15 as 40-kPa (5.8-psi) peak, 285-kPa.msec (41.1-psi.msec) impulse, these may not be adequate for the charge weight and standoff distance applicable to a given project. This can be a source of some confusion among specifiers. Also, as noted, UFGS allows only minor departures in size and configuration between tested windows and those to be used for any given project. For each combination of pressure and impulse, a minimum of three identical specimens is required by ASTM F1642.

UFGS-required submittals include design data such as calculations prepared and signed by a registered professional engineer, as well as air-blast test reports. The latter is only included when it is employed as an alternate validation method.

For project delivery, many military projects require the use of the SpecsIntact[10] system for creation and maintenance of specifications to be included in bid documents and contract documents. This automated system for preparing standardized facility construction specifications is a NASA software product, developed and maintained under the Information Management Communications Services (IMCS) at the Kennedy Space Center. SpecsIntact uses MasterFormat 2010 and includes functionality such as project entry, management, tracking, automatic updates for latest specifications, revision redline feature, and automated PDF and Word publishing with integrated bookmarking.

GSA requirements

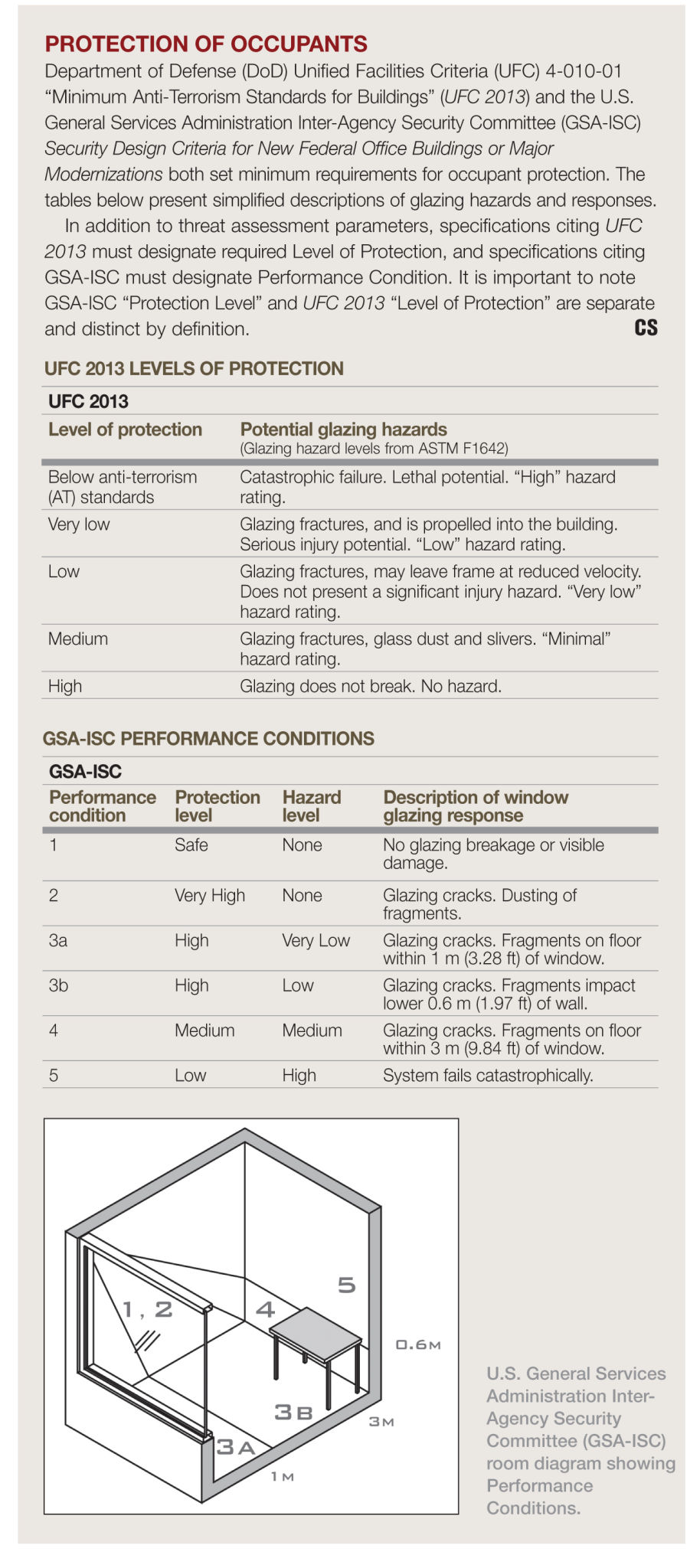

Requirements for other government agencies’ buildings—courthouses, offices, and essential facilities—are often based on the U.S. General Services Administration Inter-Agency Security Committee (GSA-ISC) Security Design Criteria for New Federal Office Buildings or Major Modernizations. GSA is the manager of thousands of federal properties; of the 1.2 million employees whose workspace is provided by GSA, approximately half are housed in buildings owned by the federal government and the others housed in separate leased facilities.

[11]

[11]Blast hazard mitigation design requirements determined by GSA-ISC Security Design Criteria are often more stringent than those determined by UFC 2013, since GSA buildings located on a typical commercial site often lack the controlled perimeter of a military facility. Threat assessment for GSA facilities is an involved, complex, and often confidential process beyond the design team’s scope. This is especially true when responding to GSA solicitations for development of leased space, which may only call for “shatterproof” glass or the application of films.

It is important to clarify expectations of GSA or the agency to occupy the lease space before finalizing fenestration product specifications.

Inelastic dynamic structural analysis typically is used for framing design, based on peak pressure in kPA (psi), impulse in kPA.msec (psi.msec), and Performance Condition as defined in the GSA-ISC. Framing is designed so glass develops its full design structural capability.

As for military buildings, determination of peak pressure, impulse, and Performance Condition (to include Hazard Condition and Protection Level) for GSA buildings is the responsibility of the owner’s security/blast consultant—not that of the window manufacturer or installer. Design parameters typically range from 27.6-kPA (4-psi) peak and 193.1 kPA.msec (28 psi.msec) impulse, up to 68.9-kPA (10-psi) peak and 613.6 kPA.msec (89 psi.msec) impulse or more.

Given these design parameters, all calculations should be prepared by a registered professional engineer directly contracted by, or in the employ of, the window manufacturer or the glazing subcontractor. Calculations from other projects, non-representative test results on other systems, or other qualitative analysis generally are unacceptable substitutes for project-specific calculations.

| AAMA 510-14 |

|

The American Architectural Manufacturers Association (AAMA), working in conjunction with interested stakeholders from the public and private sectors, has developed AAMA 510-14, Voluntary Guide Specification for Blast Hazard Mitigation for Vertical Fenestration Systems. This publication addresses many of the issues that arise when writing project specifications for blast hazard-mitigating windows, curtain wall, and storefronts—especially for those buildings not under U.S. Department of Defense (DoD) or General Services Administration (GSA) jurisdiction, but still desiring blast hazard-mitigating design. It also provides definitions, a comprehensive list of references, representative test specimen sizes and configurations, forms for product certification, excerpts from Unified Facilities Criteria (UFC) 4-010-01, “Minimum Anti-terrorism Standards for Buildings” (UFC 2013), GSA-ISC and ASTM F2912, Standard Specification for Glazing and Glazing Systems Subject to Air-blast Loadings, as well as other useful information. It is available via www.aamanet.org/general/1/45/publication-store[12]. |

Prescriptive requirements, used in conjunction with inelastic dynamic structural analysis, helping ensure compliance with the GSA-ISC often include, but are not limited to:

- limiting rotation of any framing member supporting laminated glass when under load;

- keeping all framing member stresses to less than or equal to full Yield Strength (Fy) for the alloy and temper used;

- sizing and designing anchors and connections with ductile failure modes to exhibit stresses less than or equal to Ultimate Strength (Fu);

- designing masonry anchors in concrete to fail before their substrate splits, spalls, pulls out, or has a bearing failure; and

- providing the registered professional engineer with statistically valid survey data verifying design strength of in-place concrete or other masonry substrates, including the lower limit of the confidence interval to be used by the manufacturer in structural calculations.

In cases where connections’ failure mode is non-ductile, the code or manufacturers’ allowable design values must be used.

Anchors cannot be connected to a building’s columns, unless specifically shown on architectural and structural drawings, and approved by the building’s engineer of record against the potential for progressive collapse. If welded connections are used at windows, sub-frames, or other connections, the weld shall never be the weakest point through which loads are transferred back to the building structure.

As in UFC 2013, in addition to blast loads, all components must be designed to satisfy applicable code requirements for adequate glass support, wind, and gravity loads.

As a specifier, mixing UFC 2013 and GSA-ISC criteria in the same project specification needs to be avoided.

Impact loading from the inside and outside

Stronger, stiffer glass can have a significant effect on structural design of the window framing used to support it. This is because framing design must be based on the glass makeup actually being employed, not on some minimum acceptable makeup meeting blast requirements. Some of the applicable programmatic or code-mandated requirements leading to the use of stronger, stiffer glass include:

- bullet-resistance (ballistic glass);

- hurricane impact requirements in coastal areas;

- tornado resistance;

- vandal deterrence;

- breaching and forced entry;

- human impact resistance in psychiatric or behavioral care occupancy; and

- detention applications.

Many of these added requirements apply to DoD and GSA buildings, or other facilities designed with blast hazard mitigation in mind. Many are considered essential facilities requiring enhanced protection, as defined in ASCE 7-10, Minimum Design Loads for Buildings and Other Structures, for Risk Categories III and IV. Examples include large hospitals, utilities, public safety buildings, and storm shelters.

Conclusion

Since windows and curtain walls encounter the extreme pressure released by an explosive mass, all elements of the assembly work together. Modern, blast-mitigating assemblies are intended to be flexible and absorb blast energy, creating elegant, quiet, daylight-filled, environmentally responsible, and safe buildings.

Experienced window and curtain wall manufacturers and blast consultants can interpret the lexicon of blast hazard mitigation, and design for safety and cost-effectiveness. Whether undertaking blast-hardened re-cladding of an existing building, hazard-mitigating replacement windows, or a modern all-glass façade for a new building, it can be especially helpful to use their technical expertise from inception through completion.

[13]

[13]

Tom Mifflin serves as Wausau Window and Wall Systems’ governmental and military market manager. He works closely with architects and specifiers to assist with their window system selection and design. Mifflin is involved with high-security and blast-mitigating window systems for new construction and renovation projects, such as base realignment and closure and energy-improvement projects. He draws from more than 20 years of experience interpreting the government facility standards and security design criteria to ensure windows or curtain wall are capable of meeting the specified level of protection. Prior to Wausau, Mifflin worked as a design engineer for a government subcontractor working on classified projects for the Naval Facilities Command (NAVFAC). He can be contacted at tmifflin@wausauwindow.com[14].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/blast_Wausau_VA_FairfaxCtny_Exterior1_TrevorOlson.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/figure-1.jpg

- Unified Facilities Criteria (UFC): http://www.wbdg.org/ccb/browse_cat.php?o=29&c=4

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/figure-2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/edit13.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/blast_Wausau_CA_LAPD-interior_photoby-TimGriffith-copy.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/edit21.jpg

- Energy-Efficiency Standards and Green Building Certification Systems Used by the Department of Defense for Military Construction and Major Renovations: http://www.nap.edu/catalog/18282/energy-efficiency-standards-and-green-building-certification-systems-used-by-the-department-of-defense-for-military-construction-and-major-renovations

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/blast_Wausau_NC_MecklenbergCrths_BrettDrury.jpg

- SpecsIntact: http://specsintact.ksc.nasa.gov

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/blast_Wausau_WI_WausauNatlGuard_SW.jpg

- www.aamanet.org/general/1/45/publication-store: http://www.aamanet.org/general/1/45/publication-store

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/10/protection.jpg

- tmifflin@wausauwindow.com: mailto:tmifflin@wausauwindow.com

Source URL: https://www.constructionspecifier.com/protecting-those-inside-specifying-blast-hazard-mitigating-windows/