by David E. Sacks, R.A., AIA, LEED AP, and Bradford S. Carpenter, PE, LEED AP

Historically, glazing has been used to provide light and ventilation in building walls as its primary function. In contemporary buildings, specialized glazing can provide numerous other functions, including fire-resistance.

The percentage of glazed surface area on buildings continues to increase. One of the reasons is the link between access to natural light and improved health, comfort, and productivity of occupants. This factor, along with the energy costs associated with internal lighting and the resulting cooling loads, have focused attention on the positive attributes of daylighting, in turn driving both policy and architectural aesthetic toward greater use of glass in the building enclosure.

This desire to maximize glazed surface area has been a major factor in the development and increased acceptance of fire-rated curtain-wall glazing systems. While the development of these products continues and manufacturers look to expand market share, the expectations of professionals and end users do not always reflect actual product performance (in terms of optical clarity and aesthetic factors like color).

Similarly, the newness of these products results in undeveloped standards and codes, not fully equipped to check or maintain quality control. Additionally, the infancy of product to the construction market also causes contractor unfamiliarity. Fire-rated curtain wall assemblies are inherently different from non-rated curtain wall assemblies with respect to physical characteristics and installation and handling requirements.

Background

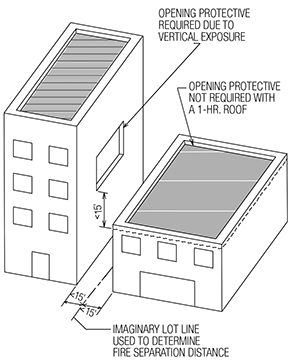

Fire separation distances between adjacent buildings (and stepped portions of the same building) trigger specific code requirements regarding fire-resistance ratings and maximum area of exterior wall openings (Figure 1). Historically, fire-resistance-rated walls have been solid masonry, concrete, or similar non-combustible construction with limited fire-protected openings to fulfill fire-escape egress and light or vent requirements. These openings would be protected with fire-protective-rated window and/or door assemblies—typically, steel fenestration glazed with wired glass or individual units of glass block. The building code further restricts the height, width, and overall area of each glass panel in a fire-protective-rated opening.

In 2006, the revision to the International Building Code (IBC) included a new section, Section 706.2.1–Fire-resistance-rated Glazing, which was added to clarify the distinction between fire-resistance-rated glazing and fire-protection-rated glazing.

While both types of glazing limit the spread of flames during a fire, fire-resistance-rated glazing also provides a radiant barrier. As such, this glazing may be used to construct the fire barrier—in other words, it is the fire-resistance-rated wall, not just a protective opening in said wall. The 2012 IBC went a step further in clarifying the role of fire-resistance-rated glazing when it published Table 716.3, “Marking Fire-rated Glazing Assemblies.” This table states the “W” marking classifies an assembly as “meeting fire-resistance-rated wall assembly criteria.” The development of intumescent fire-rated glazing—which meets IBC 706.2.1—was a catalyst behind this change.

Intumescent

The term ‘intumescent’ characterizes a material that swells and chars when exposed to flame, forming an insulating fire-retardant barrier between the fire and the material. The development of intumescent materials—such as hydrated sodium silicate, graphite, and mono-ammonium phosphate (MAP)—has enabled glazing systems to make the leap from fire-protective to fire-resistant. As such, the creation of fire-resistive glazing assemblies has virtually erased the limitations on which building surfaces can or cannot be glazed. This has enabled architects to design with more transparent fenestration systems in an effort to achieve aesthetic goals or maximize daylight.

Manufacture and assembly

In order to create intumescent laminated glass, large sheets of annealed glass are set onto horizontal racks with a silicone bead along the perimeter to create a reservoir that is then filled with hydrated sodium silicate in either liquid or prill (i.e. bead) form. Each sheet is then low-baked (<37.7 C [<100 F]); once the intumescent material is set, the perimeter is trimmed off to remove the silicone bead. This process precludes the use of heat-treated glass as the base product in an intumescent laminated glass assembly.

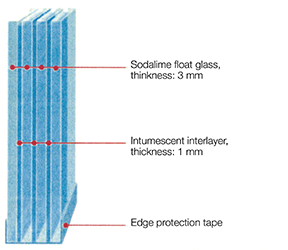

The individual intumescent laminated sheets are then configured according to the desired fire-rating requirements, and baked in an autoclave at a slightly higher temperature to create the final sandwich panel (Figure 2). When that panel is intended for a monolithic installation, an additional layer of glass with a polyvinyl butyral (PVB) lamination is added to one side (i.e. asymmetric) or both sides (i.e. symmetric) of the sandwich panel, depending on the intended use. The panels are then cut to size with a diamond-blade saw and the edges sealed with a special metallic perimeter tape to protect the intumescent interlayer during transportation, construction, and in service.

Material and system limitations

Since the intumescent lamina is not inherently stable, it needs to be protected to prevent deterioration through absorption of atmospheric moisture and general exposure to the atmosphere. Hydrated sodium silicate, which is frequently used as the lamina material, is particularly sensitive to high temperatures, ultraviolet (UV) radiation, and water—a significant challenge, particularly for applications as exterior fenestration glazing. As such, the PVB lamination at the exterior face, the perimeter edge tape, and the unit’s general storage/handling are critical to the sandwich panel’s performance and they hint at the intumescent material’s limitations.

Several intumescent glass manufacturers indicate products must be protected from temperatures at or above 50 C (122 F). This limitation applies to internal (i.e. radiators or halogen lights) and external sources of heat. Additionally, particular attention should be paid to where the external sheet of glass is made of highly absorptive glass (e.g. body-tinted). This temperature sensitivity will limit the applicable climates as well as specific exposures where this glazing may be installed.

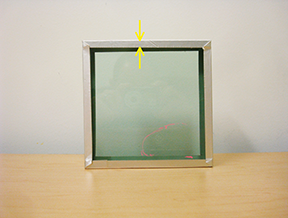

The special aluminum tape along the edges provides protection against moisture and general exposure to the atmosphere (Figure 3). Should the tape lose adhesion and become de-bonded before installation in the fenestration system, it must be replaced or taped over prior to installation, and this may have an impact on the product warranty.

One manufacturer’s product warranty, for example, states: “The removal of edge tape from the laminated assembly voids the warranty.” For a full-frame system, where the edges of glass are concealed by the metal frame, the edge tape typically returns to each face of glass 6.35 to 9.5 mm (1?4 to 3?8 in.). However, in a butt-glazed configuration, the edge tape does not return to the face of the glass and is much more susceptible to damage during the handling and installation processes.

The application of PVB at the exterior face of all intumescent glazing units reduces UV degradation to the intumescent material, and it is critical for asymmetric units that the non-PVB protected face not be exposed to UV during transport, storage, or installation. Manufacturers provide their products with a stamp readable from the UV-opposed side as ?a guide to installation contractors.

Beyond just the glass orientation, the product’s installation procedure varies greatly from that of a typical curtain wall system. While a traditional curtain wall may use a pressure-glazed system with a pressure bar to seal the gaskets to the glass surface, intumescent laminated glass systems often require only a fraction of that pressure.

On reviewing the product documentation and installation manual of one fire-rated curtain wall system, one manufacturer specifically notes:

Edge pressure must be between 4–10 pounds per linear inch. This pressure is required on the (curtain wall system’s) mullion gaskets. It must be uniformly applied by the exterior-mounted pressure plate, through the glass to the mullion gaskets. Excessive edge clamping pressure will cause deformation and breakage.

The installation manual goes on to describe the pressure plate installation: “Tighten the screw until a maximum of 1.13 to 1.69 Nm (10 to 15 in. pounds) of rotational torque is achieved.” As a point of reference, one non-fire-rated curtain wall system manufacturer states in its literature to torque all pressure plate bolts to 5.65 Nm (50 in. pounds).

As implied by the reduced pressure, intumescent laminated glass manufacturers specifically indicate their glazing systems are not intended for use in pressure-glazed curtain wall systems. Instead, the systems typically employ a glazing tape between the frame and the glass when setting the glass and potentially an additional bead of silicone sealant tooled to be water-shedding on the exterior face. Some manufacturers do not warrant the air and water integrity of a fire-rated curtain wall system if a primary perimeter sealant joint is only installed at the exterior pressure plates or cover caps.

Visual aesthetics and defects

The visual quality of any laminated glazing system will not match that of a non-laminated system, which uses the same glass components. The same holds true when the lamination is an intumescent product. In an effort to mitigate this difference, many manufacturers offer intumescent laminated systems with low-iron glass, which provides higher optical quality (i.e. greater light transmission and less color).

Intumescent laminated glass products are available with low-iron glass. However, sample warranties for these products also include language noting the impact of intumescent interlayers on optical clarity. One product warranty reads:

Due to the nature of its interlayers, (said product) may develop some minor imperfections such ?as small bubbles or a slight distortion which ?will not affect the free vision through the glazing or fire performance. A variation of up to 5% of light transmission or haze shall not be considered a defect.

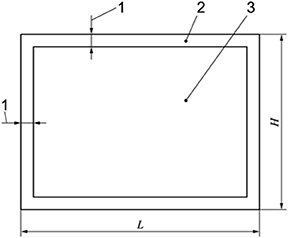

Unfortunately, expected or allowable visual defects in intumescent laminated glass are not well defined in the United States. (See Figure 4 for an example of creasing and/or streaking.) International Organization for Standardization (ISO) 12543-6, Glass in Building–Laminated Glass and Laminated Safety Glass, Part 6: Appearance, is widely accepted throughout Europe, and several manufacturers base their in-house quality control guidelines on this standard. Currently, there is no equivalent standard published by ASTM or American Architectural Manufacturers Association (AAMA) for the United States. As a result, the only guideline by which to evaluate laminated glass is that offered by the manufacturers.

ISO 12453-6 divides the glazing material into a perimeter section, referred to as the ‘edge area’ and a remainder of the glass, referred to as the ‘vision area.’ The edge area is intended to be concealed by the frame, and therefore the standard allows for more defects in this portion of the glazing relative to the vision area (Figure 5). Published quality control literature for one manufacturer shows a modified version of the ISO 12543-6 (Figure 6).

For a 2 x 2.5-m (6.5 x 8.2-ft) sheet of intumescent laminated glass, this modification effectively increases the size of the edge area by 42 percent, increasing both the total allowable defects in the glass and the likelihood those defects will be visible in service. This modification to the standard implies that the industry struggles with consistency and overall quality control, which places an increased burden on the contractors and design professionals involved.

Conclusion

Intumescent laminated glass can be an effective fire-resistive product, both aesthetically and functionally, for architects and building occupants. Intumescent glass products provide a level of fire-safety far exceeding that of other glazing products. These authors expect intumescent laminated glazing systems will continue to grow in market share in the future. With this growth, it is important building owners, contractors, and architects understand the limitations of these products to better inform their practices and clients, and building standards remain current with building technology.

Until better industry standards for aesthetic quality are developed in the United States, these authors recommend design/construction professionals educate clients on the optical limitations of intumescent laminated glass before specifying those products. If a nearby project used this technology, one should take the client to see it firsthand. It is also recommended specifiers reference the existing European standard, ISO 12543-6, until local standards catch up.

Similarly, a typical curtain wall contractor will likely not understand the nuances of edge pressure and torque limitations or the sensitivity to water and UV of intumescent laminated glass until they experience it for themselves. The lack of industry experience with the installation (and handling) of these products underscores the value of a mockup, which should be created, especially for new products.

David E. Sacks, R.A., AIA, LEED AP, is a senior staff member in the Building Technology Division of Simpson Gumpertz & Heger (SGH), a national consulting engineering firm active in building rehabilitation, enclosure consulting, and structural engineering. He is experienced in the investigation and evaluation of building enclosures, including roofing, below-grade waterproofing, and wall and glazing systems, with a specialty in repair and rehabilitation of existing buildings. Sacks’ professional experience includes the investigation and restoration design of existing low-rise, mid-rise, and high-rise residential and commercial buildings, with exterior envelopes consisting of architectural terra-cotta, brick, stone, and modern curtain wall systems. He can be reached at desacks@sgh.com

Bradford S. Carpenter, PE, LEED AP, is an associate principal and vice-president in the Building Technology Division of SGH. He has more than 15 years of experience investigating, repairing, and designing building enclosure systems of all types. Carpenter is a member of the American Architectural Manufacturers Association (AAMA), a past co-chair of the Washington, D.C. Building Enclosure Council (BEC|DC), and a frequent speaker and author on building enclosure topics including design and performance. He can be reached at bscarpenter@sgh.com

The authors are addressing a developing segment of the industry which is responding to needs for an open look as well as the increased requirements for infill construction which has to follow the approach that fire must be contained within a compartment, or in this case, the building envelope.

In describing the glass unit, a laminated intumescent, the authors have used as their model an approach from one manufacturer, not that used by two other major forces in the USA market, which leaves room for discussion as to the values of other glass fabrication approaches. The others may not typically have the same edge limitations and intolerances as the product described.

In addition the authors would tend to leave the impression that the fire rated characteristics may override the typical review of the “system” which is the pairing of appropriately designed framing and laminated intumescent glass, which, besides the required fire testing to conform to ASTM E119 or UL263, as required per Code, would also need to meet the other requirements for an exterior glazed system. These would include the familiar air infiltration, water resistance, static and dynamic pressure testing. Rated system which are used for exterior applications are required, per Code, to be so tested in addition to their fire rating, and such results must be among the other information reviewed by designers.

Currently there are at least three such systems tested, and these do differ in their options, exterior performance levels, as well as the manufacturer’s recommendations for installation. One system uses special EPDM gaskets which are supplied by the manufacturer as part of the framing system, and does not require the use of a silicone sealant for primary or secondary sealing. The system is not only used on exterior applications for “normal” projects but also qualifies for use in HVHZ (high velocity hurricane zones) which testing includes small and large missile impact testing in addition to the other requirements.

The article is a first step, but should be updated and expanded to better represent the options available in the industry, which in part has expanded the European systems in use for several decades, and which are responding to the needs of the USA and North American market. There is no argument that select European standards may be guides for internal reviews, but adopted Code standards do have differences and may require additional levels of performance not covered by those guides, so extreme care is called for.

It would be extremely beneficial to better inform the construction industry served by CSI by a better and expanded comparison to educate the readers that depend on a wider view that the limited scope presented, probably due in part to the limitations imposed for space.

Remberto brings up some very important points. There are two primary types of fire-resistive rated glass used in curtain wall systems; they either fall into the category of intumescent laminated glass or gel glass. Intumescent laminated glass uses multiple layers of interlayers in solid form which are in the region of 1.5mm thick. Gel glass on the other hand uses a much thicker reservoir of clear insulating gel (up to 13mm thick) retained between two (or more) layers of glass.

This article, which focuses on intumescent laminated glass, is the first in a series of articles about fire-resistive glazing systems; there will be a forthcoming article focusing solely on gel glass and we are hoping to have an additional article focusing on the use of these glasses in fire-rated curtain wall systems.

We are hoping that this series of articles will provide a good introduction to fire-resistive glazing.

Hello, can you share whether there was a gel glass article written ?

Thank you

Chris McGrory

610-574-2420

Gentlemen,

I hope you can assist in answering this questions:

We have several large gel filled fire rated windows in our Central Utilitiy Plant. The windows have developed lines in the gel that appear as cracks. The glazing is intact.

1. Can you speculate as to what might cause the cracks in the gel?

2. Does this affect the fire rating?

We are replacing the windows but would like to provide our property owners with viable answers to their questions.

Thank you.

Rose*

Rose,

Please email me (desacks@sgh.com) a couple photographs so that I might better understand the types of failures that you’re describing.

Thank you,

David Sacks