Quantifying savings with infrared-reflective metal coatings

Energy costs were found using U.S. average rates for commercial customers, as of September 2009, provided by EIA. Electricity cost was $0.1051/kWh and natural gas was $0.898/therm.

The study assumed the use of thermally broken frames to produce conservative savings estimates. Frames without a thermal break have default U-values double those of the frames modeled in this analysis. Thermal break frames are common in cold climates, but less so in warm climates, where heat gain reduction from low-reflectance coatings is most valuable.

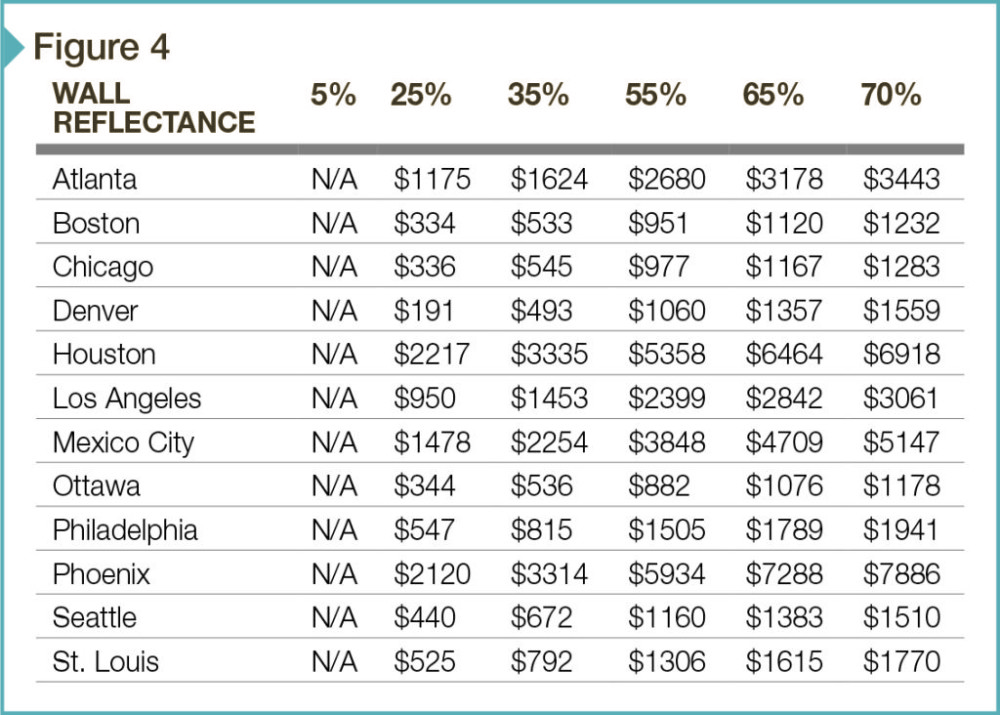

Results for reflective wall coatings

The price difference between standard fluoropolymer coatings and heat-reflective coatings for metal wall, window frame, and roof applications is relatively minor, yet the study demonstrated the small premium will pay for itself many times over in savings. This finding was consistent even in cold climates—cities such as Boston, Chicago, and Ottawa—where the modeled energy savings are smaller than for warmer locales.

Figure 4 shows annual energy cost savings realized on the modeled building with metal wall coatings with reflectance rates of five to 70 percent in 12 major cities encompassing a broad spectrum of climates.

Figure 5 shows the design airflow reduction. Combined with other measures, reflective wall coatings may enable smaller air-handling unit (AHU) sizing, or reduced fan speed and fan brake horsepower (BHP) in the same AHU. As expected, the greatest capacity reductions are realized in hot, sunny climates.

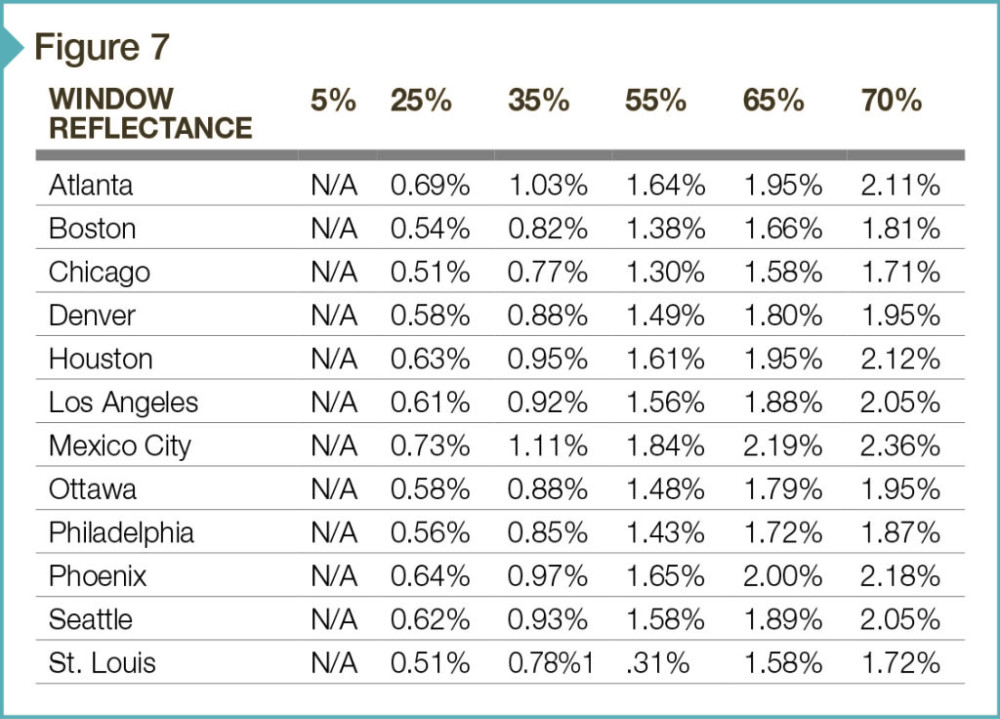

Results for reflective window frames

Figure 6 illustrates annual energy cost savings realized on the modeled buildings with window frame coatings with reflectance rates of five to 70 percent.

Figure 7 shows the design airflow or fan-sizing reductions that potentially can be achieved by using reflective metal coatings on window frames. The savings may not be significant by themselves, but they can be substantial when combined with cost reductions provided by other reflective-coated building components.

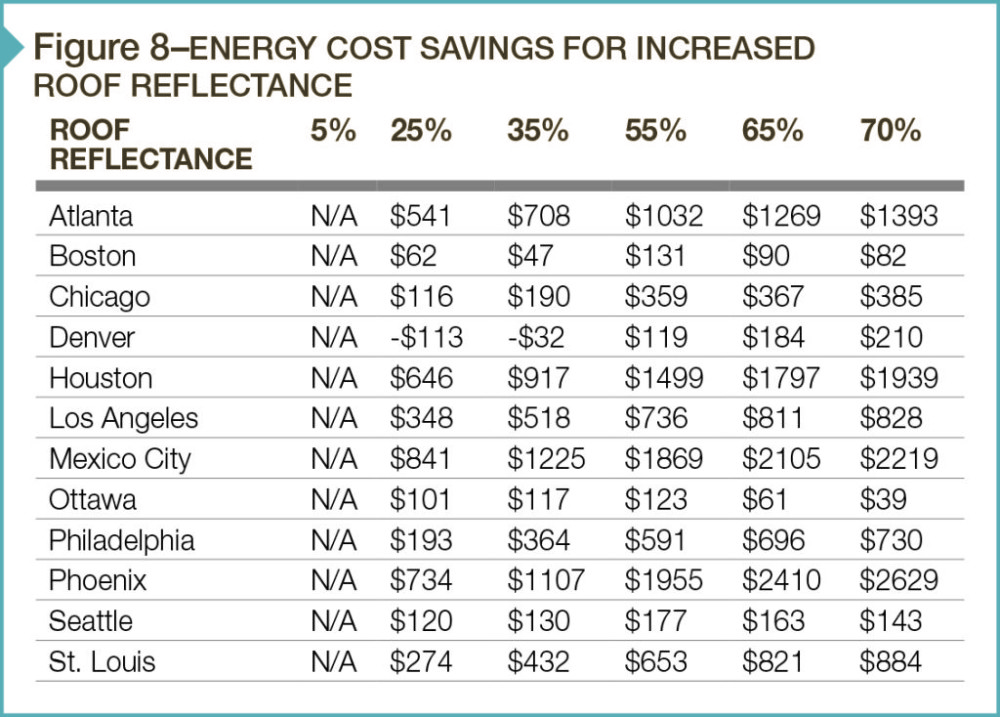

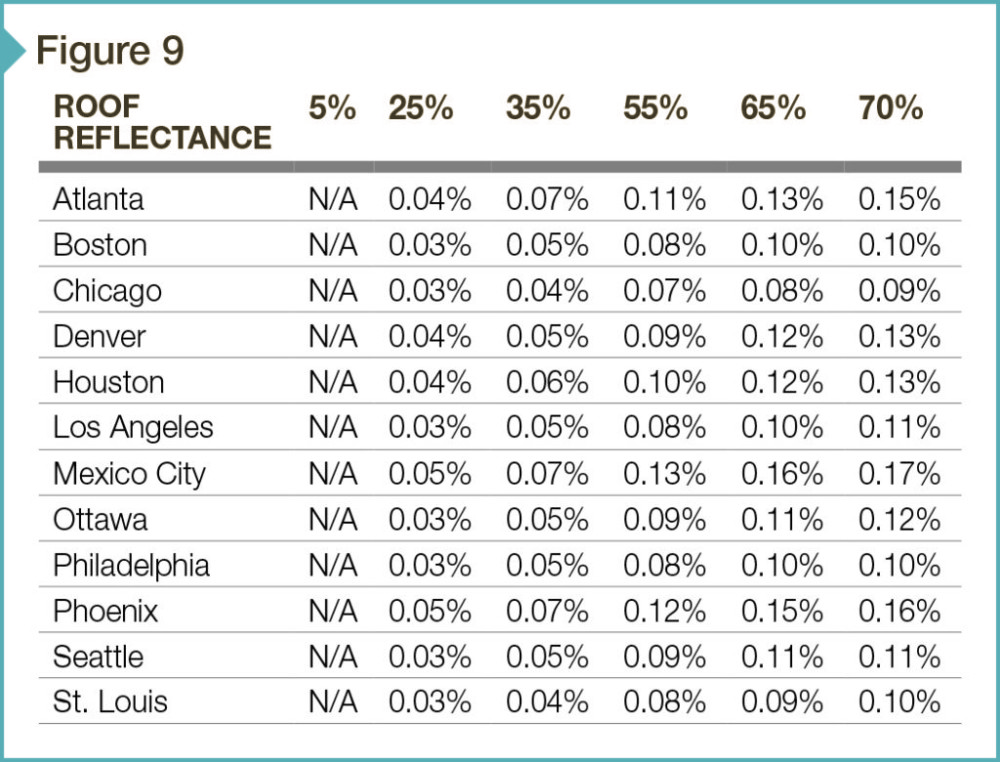

Results for reflective roofs

Figure 8 shows annual energy cost savings realized on the modeled building with roof coatings with reflectance rates of five to 70 percent.

Figure 9 illustrates the modeled airflow reduction for buildings with reflective roof coatings. They are smaller than other air flow reductions for walls and window frames because the roof area on the modeled building is small in proportion to the wall and window areas.