R-values: Controversy and performance values

by eyetee | November 4, 2013 2:01 pm

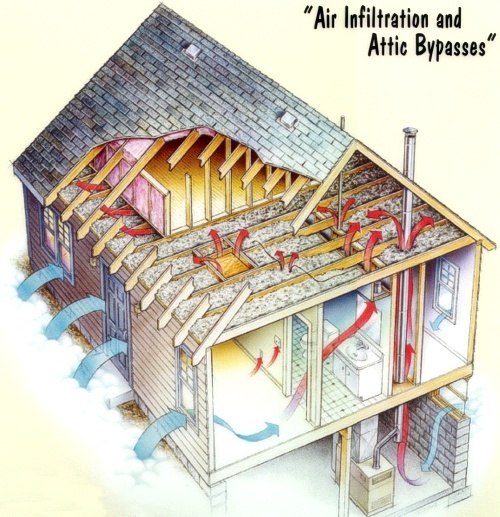

Image © www.energydetectivetn.com[1]

by Ken Wells

What exactly is R-value? This question is not asked often enough in today’s environmentally conscious design/construction industry. However, an even better question may be, whether R-value is still a valid unit of measurement for the performance of insulation products. (And, if not, why is it being used as the predominate gauge to compare them.) To answer these questions, this two-part series discusses how R-value came to be and how it is used.1

R-value is mostly known as a simple rating system for building insulation products. Scientifically and under uniform conditions, it is the ratio of temperature difference across an insulator and heat flux (i.e. heat transfer per unit area). In accordance with the Federal Trade Commission (FTC):

R-value is the recognized numerical measure of the ability of an insulation product to restrict the flow of heat and, therefore, to reduce energy costs. R-values may be expressed per unit of thickness (e.g. 25 mm [1 in.]) or for the total thickness of a particular insulation product or installation. The higher the R-value, the better the product’s insulating ability.

A plaque at Penn State University, where R-values were created, reads:

R-values: Standardized measures of resistance to heat transfer were first proposed in 1945 by Everett Shuman, who as director of Penn State’s Building Research Institute, continued to promote their adoption. R-values were later widely applied to industrial and residential insulating materials and helped consumers make more energy efficient choices.

The Federal Trade Commission has also recognized the importance of energy expenditures on housing to homeowners and other consumers. In 1979, it promulgated the “R-value Rule”—16 CFR Part 460, “Labeling and Advertising of Home Insulation: Trade Regulation Rule; Final Rule.” It requires thermal insulation manufacturers to disclose product’s thermal performance based on uniform industry testing procedures, such as a guarded hot plate assembly. The purpose was “to provide consumers with information about thermal insulation products, based on uniform standards, that allows them to make meaningful, cost-based purchasing decisions among competing products.”

In the past, when energy was cheaper, little thought went into efficient building design, and there were even less associated products. The building industry did the best it could, with what was available. Then, as energy prices rose, heating and cooling costs became an issue. Buildings account for about 40 percent of U.S. energy demand, as well as 40 percent of its carbon dioxide (CO2) emissions, according to the U.S. Department of Energy’s (DOE’s) 2008 report, “Energy Efficiency Trends in Residential and Commercial Buildings.”

In the past, when energy was cheaper, little thought went into efficient building design, and there were even less associated products. The building industry did the best it could, with what was available. Then, as energy prices rose, heating and cooling costs became an issue. Buildings account for about 40 percent of U.S. energy demand, as well as 40 percent of its carbon dioxide (CO2) emissions, according to the U.S. Department of Energy’s (DOE’s) 2008 report, “Energy Efficiency Trends in Residential and Commercial Buildings.”

Further, in 2005, DOE found commercial buildings accounted for approximately 18 percent of total energy use in United States and 35 percent of total electricity consumption. More than 60 percent of commercial building energy use is attributable to losses through walls, foundations, and roofs due to air infiltration or exfiltration. Energy costs account for approximately 30 percent of a building’s total operating costs. According to the Environmental Protection Agency (EPA), the savings potential from the proper design and installation of energy-efficient upgrades is more than 35 percent—for example, approximately $25,000 for every 2322 m2 (50,000 sf) of office space.2

As consumers and contractors push to implement these modifications, there has been a great demand for products and techniques aimed at trimming energy costs. Additionally, consumers have become more aware of the effects and impacts of energy consumption and carbon footprints. The building industry is now under an intense spotlight with regard to its considerable energy consumption and associated carbon emissions. Reducing a structure’s ecological impact, through effective, high-performance insulation systems, is becoming a priority.

At the base of the R-value issue there is controversy. FTC defines the R-value’s purpose as:

a way for consumers to evaluate how well a particular insulation product is likely to perform, to determine whether the cost of the insulation is justified, and to make meaningful, cost-based purchasing decisions among competing products.

There is a critical need for an accurate means to evaluate and compare the true performance of building insulations. However, does R-value really help consumers make energy-efficient choices? Or has today’s building science and high-performance insulation systems outgrown the metric as an accurate, and reliable, measurement of insulation’s real-world performance?

The second part of this two-part series will discuss real-world R-value applications, various insulation materials, and how the industry is moving toward developing an accurate evaluation tool.

Notes

1 The opinions expressed in this article are based on the author’s experiences and do not necessarily reflect those of CSI or The Construction Specifier.

2 See Honeywell’s “Insulation Energy Savings: Key Issues and Performance Factors” at www.cufca.ca/tech/Honeywell_Insulation_Energy_Savings.pdf[2].

Ken Wells has been part of the insulation industry for more than 17 years. In 2006, he started Elite Insulation & PolyPro LLC with his brother Chris, and father Bob; the company has been recognized with two National Industry Excellence Awards from the Spray Polyurethane Foam Alliance. Wells can be contacted at kwells@polyprollc.net[3].

- www.energydetectivetn.com: http://www.energydetectivetn.com

- www.cufca.ca/tech/Honeywell_Insulation_Energy_Savings.pdf: http://www.cufca.ca/tech/Honeywell_Insulation_Energy_Savings.pdf

- kwells@polyprollc.net: mailto:kwells@polyprollc.net

Source URL: https://www.constructionspecifier.com/r-values-controversy-and-performance-values/