Rainscreen walls: An updated definition for today’s construction environment

by sadia_badhon | August 6, 2020 10:35 am

by Richard Martens

[1]

[1]The term rainscreen is widely used to describe a building products category that fulfills one of the main functions of an exterior wall—to screen out rain and keep a wall dry.

What makes up a rainscreen? How is it defined, and what are its components? Moreover, what can be expected from a rainscreen wall?

Wikipedia describes a rainscreen as “an exterior wall detail where the siding (wall cladding) stands off from the moisture-resistant surface of an air barrier applied to the sheathing (sheeting) to create a capillary break and to allow drainage and evaporation. The rain screen is the siding itself but the term rainscreen implies a system of building.”

Consider some historical interpretations of a rainscreen wall.

In 1990, Madeleine Rousseau, a well-respected research officer at National Research Council Canada (NRC) described a controversy over the difference between a drained cavity wall and a rainscreen wall (read “Facts and Fictions of Rain Screen Walls” by Madeleine Z. Rousseau, MRAIC, in Construction Canada [March/April 1990]).

“Now a heated debate on terminology usually starts!” she noted. “Usually, the debate cools off when the expression ‘pressure-equalized’ is used.”

Rousseau went on to illustrate a compartmented wall with a 115-mm (4 ½-in.) cast concrete air barrier behind each compartment. Cast concrete is seldom used as an air barrier these days, and pressure equalization has lost favor as a means of controlling bulk water intrusion. However, the principles of rainscreen walls outlined by G. K. Garden in his influential 1963 article, “Rain Penetration and its Control,” in the Canadian Building Digest remain relevant and provide guidance to modern exterior wall design (for more information, read “Rain Penetration and its Control” by G. Kirby Garden).

[2]

[2]“Rain penetration results from a combination of water on a wall, openings that permit its passage and forces to drive or draw it inward,” noted Garden. “It can be prevented by eliminating any one of these three conditions.”

Garden further defined six forces that drive or draw liquid water into a wall system. They are:

- Kinetic energy (driving rain);

- Capillarity (water moving by capillary attraction);

- Gravity;

- Wind pressure;

- Pressure differences; and

- Pressure differences + capillarity.

Garden regarded pressure equalization as a means of controlling the forces driving or drawing liquid water. He maintained both water on the wall and openings permitting water’s passage would always be present.

Much has changed since Garden and Rousseau conducted their research. Construction has become more complex, new materials have come into widespread use and cost pressure on building design has intensified. There have also been substantial advances in building enclosure design.

Arguably, the most significant innovation has been the widespread use of continuous air barrier systems.

Rather than focusing on pressure equalization, an air barrier “is a system of building assemblies within the building enclosure designed, installed, and integrated in such a manner as to stop the uncontrolled flow of air into and out of the building enclosure,”(consult the Air Barrier Association of America).

This addresses one of Garden’s three conditions (openings permitting passage of water) and controls a factor he did not describe. Air moving through a wall assembly brings water with it in the form of humidity, leading to potential condensation and associated deleterious effects. Now required by code, an effective air barrier system is fundamental to every wall design.

Two of Garden’s forces involve capillary action.

Wikipedia defines capillary action as “the ability of a liquid to flow in narrow spaces without the assistance of, or even in opposition to, external forces like gravity.”

[3]

[3]It is commonly called wicking and can be seen in a lamp where oil is drawn by capillary action up the wick to the burning tip. Rousseau’s 115-mm concrete air barrier, which was porous by nature and prone to cracking over time, was also vulnerable to moisture entry by capillary action. This was controlled with an air space or cavity that needed a capillary break. In this way, water could be managed using an exterior rainscreen (the brick façade), a capillary break (the air space), and weeps to allow moisture to exit from the wall. Garden’s forces were managed.

Masonry walls of this kind represent an extreme condition. Bricks and mortar can store large amounts of water, and concrete is porous and hydrophilic, making it highly conducive to capillary water flow. As a result of this and other considerations, the air space for masonry walls must be between 25 and 168 mm (1 and 6 5/8 in.) wide, though spaces less than 50 mm (2 in.) are not usually recommended (referenced from the Brick Industry Association Technical Note 28D). More recent materials, such as oriented strand board (OSB) sheathing, also allow capillary movement of water and are more prone to moisture damage than cement.

Innovation in this area of construction materials has also been significant. Fluid-applied polymeric air and moisture barriers can effectively waterproof all code-compliant base walls, including masonry, concrete masonry units (CMUs), and both gypsum and wood-based sheathing. These materials must demonstrate the ability to resist a 500-mm (20-in.) column of water for at least five hours (according to the American Association of Textile Chemists and Colorists [AATCC] 127, Water Resistance: Hydrostatic Pressure Test). Unlike several building wraps, fluid-applied air and moisture barriers are fully adhered to the substrate and create an effective capillary break. So, in addition to sealing gaps, fluid-applied air and moisture barriers address one of the main forces that move liquid through a wall.

This takes us back to the heated controversy over cavity wall and rainscreen wall terminology, without pressure equalization to stop the debate. Clearly, any wall design carrying the “rainscreen” designation must have a gap between the outer rain screen and a drainage plane. In most cases, the moisture barrier in the drainage plane will also function as an air barrier assembly, continuously connected to the roof, foundation, window, and penetration air barrier assemblies. While a gap is an absolute necessity, how large must this gap be?

[4]

[4]The answer to this key question is specific to every wall design because the gap is called on to perform different functions. For example, all of the materials used in an exterior insulation finish system (EIFS) have very low moisture absorption. Provision for drying absorbed water is therefore less critical. Air circulation within the gap, which is sometimes associated with rainscreen terminology, is not necessary with EIFS. What is required is a gap that establishes an effective drainage plane. For this, a 1-mm (39-mils) gap has been shown to be effective (for more information, read the Canada Mortgage and Housing Corporation [CMHC] report “Monitoring the Performance of an EIFS Retrofit on a 15-story Apartment Building” and “Modeled and Measured Drainage, Storage and Drying Behind Cladding Systems” by J. Straube and J. Smegal). While larger gaps are sometimes used, they have not been shown to provide improved drainage performance (consult “Rain Control Theory” by the Building Science Corporation). EIFS, with a fluid-applied air and moisture barrier, utilizing a 1 to 3-mm (118-mils) gap to allow gravity to drain moisture out along a defined drainage plane, is consistent with the principles laid out by Garden and has proven itself to be effective, both in testing and in real-world service.

Stucco, on the other hand, has higher moisture absorption than EIFS and is often applied over building wrap. This creates a greater potential for capillary water movement, and the need for more comprehensive moisture control strategies. Introduction of a 9.5-mm (3/8-in.) drainage mat between stucco and the water-resistive barrier (WRB) within a stucco wall system has been shown to greatly reduce the incidence of moisture damage (details at “Stucco Woes-The Perfect Storm” by Joe Lstiburek). Drainage mats are sometimes marketed as “rainscreens.” They create an air gap and a capillary break between stucco and building wraps, which is consistent with rainscreen principles. By comparison, stucco directly applied to masonry is clearly not a rainscreen wall.

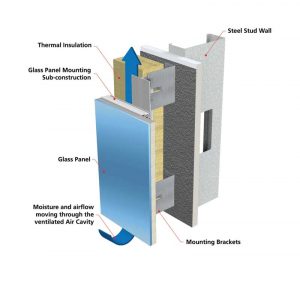

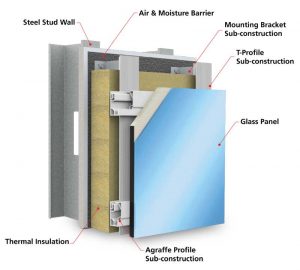

Ventilated and open-joint wall systems make further use of the air gap. By creating a convective loop outside of exterior insulation, the wall assembly dries itself continuously (Figure 1). The vast majority of water is shed by the outer rainscreen siding. Air circulation provides a means where moisture that has entered the wall (perhaps through open cladding joints) can exit. Behind the insulation, an air and moisture barrier provides a second capillary break and an additional line of defense against moisture entry. Sometimes referred to as ‘true’ rainscreen walls, ventilated and open-joint rainscreen walls make full use of Garden’s rainscreen principles.

[5]

[5]As powerful as Garden’s principles are, there are additional factors to consider. When critical building functions depend on effective performance of a single material or assembly (e.g. sealant joints), performance is directly affected by failure to install correctly or maintain that assembly. It is the elegant redundancy of moisture control combined with the passive nature of convective drying that makes ventilated rainscreen wall systems effective. Most water is stopped by the primary rainscreen—moisture entering the cavity between exterior insulation and rainscreen exits by evaporation within the convective loop and an air and moisture barrier behind exterior insulation provides an additional line of defense. There is less reliance on sealants in ventilated rainscreen walls. Where sealants are used, they are often shielded from ultraviolet (UV) exposure. This layered, redundant approach to air, moisture, and thermal management has shown itself to be highly effective.

Introduction of insulation into the wall cavity adds a further consideration regarding air gap size. Air gaps within a wall system open potential pathways for fire propagation that must be carefully evaluated. This is the case whether insulation within the gap is combustible or noncombustible. Given the complexity of flame propagation, large-scale system testing performed per the National Fire Protection Association (NFPA) 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components, or the Underwriters Laboratories of Canada (CAN/ULC) S134, Standard Method of Fire Test of Exterior Wall Assemblies, is needed to establish fire safety. Buildings employing wall systems tested per NFPA 285 have demonstrated good performance in real-world fire situations (consult Jess Beitel’s presentation on “NFPA 285 and Engineering Judgements” at the XXIII Annual Westford Symposium on Building Science). However, it must be noted both NFPA 285 and CAN/ULC S134 are system tests. Any changes in the wall system, including in the size of the air gap, affect fire performance and require expert consideration.

[6]

[6]Exterior wall system design has become far more complex than it was in Garden’s day. All components of a wall system must work in concert to manage air, moisture, thermal, mechanical, and fire performance. The system must also have the appropriate aesthetic appeal and perform at a cost that a given project can bear. Further, architects are legally required to produce designs meeting building code requirements, and the general contractor must construct code-compliant structures. This can be a daunting prospect for both the architect and the general contractor given the array of fire, moisture-resistance, and mechanical requirements placed on exterior wall systems. There is an immediately available solution to all of these challenges.

Building product manufacturers are steadily refining approaches to exterior wall design. Specific systems, be they ventilated rainscreens, stucco, EIFS, cavity wall, prefabricated panels, or masonry walls, undergo painstaking engineering review and comprehensive performance testing by leading manufacturers. These manufacturers create extensive detail sets, specifications, and installation instructions that, if followed, result in wall systems with code compliance that is confirmed by third-party documentation. Specification of these engineered wall systems allows architects to focus on attaining desired aesthetic, performance, and cost objectives. It allows general contractors to reduce risk by employing proven installation practices. Additionally, applicators can access focused technical expertise from the building product manufacturer if installation questions arise.

Designing and constructing with engineered, complete wall systems may require changes in construction processes, beginning with an appreciation that line-item value engineering of proprietary, tested, and detailed wall system creates high risk in exchange for minimal returns. For architects, matching the appearance, performance, longevity, and cost of the engineered wall systems they select to the design intent of each project represents a streamlined method of creating design value.

This principle—designing and constructing buildings with tested, code-compliant, complete exterior wall systems—forms a basis for consistent construction of buildings with improved fire safety, durability, longevity, aesthetic appeal, and cost effectiveness.

As Wikipedia noted, the term rainscreen implies a system of building. While at one time that system would have encompassed moisture control alone, the complexity of exterior wall systems now requires a more integrated approach.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/28379.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/IMG_StoVentecG_Drainage-Diagram_Steel.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/IMG_StoVentecG_Steel-Stud-Diagram_EN.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/13928-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/DSC02268.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/DSC02165.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/RM-photo.jpg

- rmartens@stocorp.com: mailto:rmartens@stocorp.com

Source URL: https://www.constructionspecifier.com/rainscreen-walls-an-updated-definition-for-todays-construction-environment/