Images courtesy State Energy Office of Arizona

Current design solutions

Many inventors and designers over the years have devised solutions that improve the performance of masonry. Exterior insulating finishing systems (EIFS) offer an acceptable single-wythe wall solution to the increasing R-values with insulation to the exterior of a mass wall. Exterior insulation can be preferable over interior insulation as it performs better thermally by protecting the thermal mass from the solar heat. Mass, properly placed and protected, makes for a highly energy-efficient building.

However, traditional EIFS does not always offer the great variety of textures, shapes, colors, and aesthetics desired by owners or architects. These systems can also potentially add significant costs in labor and materials. In other words, EIFS offers one of many solutions to single-wythe masonry design, but it is not the singular system of choice for everyone or every project.

Another solution involves hiding away the exterior insulation with a veneer (such as concrete masonry units [CMU], brick, or stone) over a block structural backup. Common practice for quite some time, these walls are generally known as double-wythe or cavity walls.

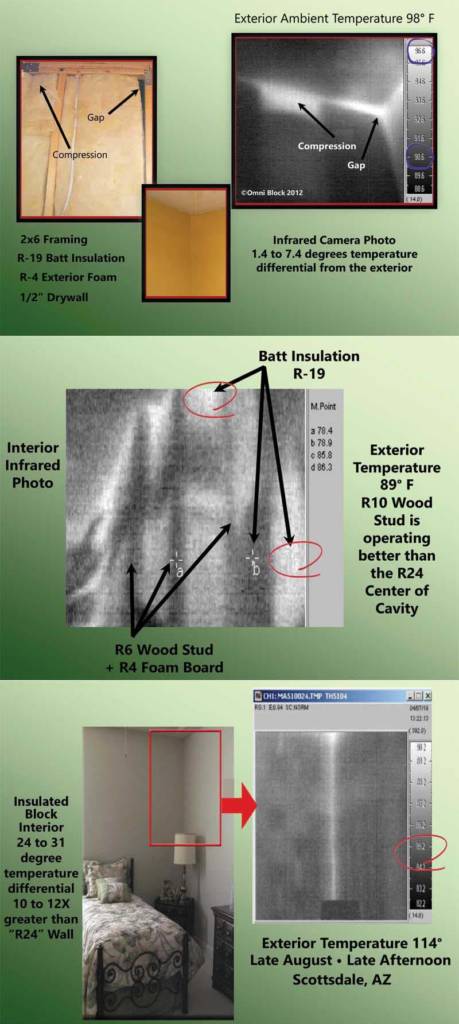

Prescriptive design methodology allows one to simply add the R-values of layered materials to reach a total R-value. For example, placing R-4 foam board over R-19 batt insulation gives one an R-23 insulating layer. Applying that same prescriptive principle to the average 200-mm (8-in.) CMU (with an R-value of 2.0) would require laying a dozen 200-mm blocks side by side to reach an R-24. Based on R-value and prescriptive design methods, a mason would have to build a block wall that is 2.4 m (8 ft) thick to match the R-value of 25-mm (1-in.) foam board covering a 100-mm (4-in.) thick batt insulation. If a building has a 2.4-m thick concrete-block wall, not much heat is ever going to make it through due to the incredible amount of thermal lag and thermal mass.

Figure 1 illustrates another point. The R-6 wood stud is performing better than the R-23 center of cavity with batt insulation and foam board. If higher R-value equates to better thermal performance and insulation, then why is the lower R-value wood stud performing better than the higher R-value insulation? Thermal mass.

Reviewing the infrared photography, one can easily see an R-23 frame wall does not operate better than an integrally insulated single-wythe CMU wall. Prescriptive design with R-value for thermal performance simply makes no sense. There are limitations to return on R-value and, as mentioned, that metric alone is not a good measure of thermal performance.

A 2013 article in SMART|Dynamics of Masonry further clarifies things, addressing the three paths to compliance for meeting the energy code. (See the 2013 issue of SMART [vol.1, no. 3] for the article, “Meeting Energy Codes with Single-wythe Masonry: COMcheck Provides Tradeoff to Compliance,” by Dan Zechmeister, PE, and Elizabeth Young.) It has taken quite a bit of time to educate architects and designers IECC does not require continuous insulation over mass walls unless a prescriptive design methodology is chosen. This process of educating and clarifying prescriptive design versus system performance versus whole-building energy analysis is still ongoing with the latter two options preferred.