Impact for LEED projects

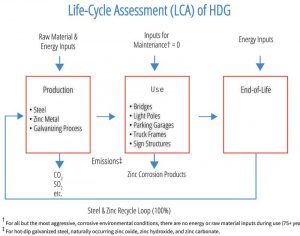

In the building industry, increased interest in using recycled and reused materials is driven by individual environmental awareness in addition to the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED) rating system. As proven and sustainable products for commercial building construction, the initial use and reuse of steel can be used to claim credits for LEED projects within the Materials and Resources (MR) category. To assist specifiers document these LEED credits, the American Institute of Steel Construction (AISC) has published separate industry-wide (generic) environmental product declarations (EPDs) for fabricated hot-rolled structural sections, fabricated hollow structural sections, and fabricated plate. Similarly, the American Galvanizers Association (AGA) has EPDs for after-fabrication, hot-dip galvanized, hot-rolled structural sections, hollow structural sections, and plate. Health product declarations (HPDs) are also available based on the type of zinc used by the galvanizer to obtain a building product disclosure optimization (BPDO) credit for selecting products that are extracted and sourced in a responsible manner.

Economic advantages

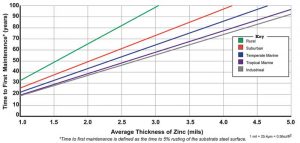

In addition to the environmental advantages, the reuse of steel provides economic savings to free up funding for new construction. The additional specification of HDG achieves many decades of corrosion protection, and thus eliminates maintenance costs in the future. Reductions in maintenance costs achieved through HDG have proven to be significant over time in comparison to other corrosion protection systems. For example, in the early 1970s an evaluation of bridges in Stark County, Ohio, determined 110 of them were structurally deficient and 50 percent of the budget was spent maintaining paint systems used to protect the bridges from corrosion. In an effort to relieve the budget of these maintenance costs, all decks and beams from the deficient bridges were removed, sandblasted, galvanized, and reinstalled using the original steel components (Figure 4). Thanks to HDG, these bridges are still rust-free and maintenance-free today. The resultant savings motivated the officials to convert all painted guardrail in the county to galvanized by reusing the steel. By 1987, the cost of paint maintenance for the department declined to less than 10 percent. With the potential for great economic savings, specifiers can benefit from similar evaluations for reuse.

Reuse of steel and galvanized steel

As long as the steel has not suffered from severe corrosion, there is a variety of ways the material can be reused and recycled without increasing construction waste or impacting future recyclability. The steel can be reused in place, reinstalled at another location, or reclaimed for fabrication on a new project. Options to reuse the steel include but are not limited to:

- expand or modify existing structure;

- reclaim for a different construction use without reprocessing the material; and

- galvanize, strip, or regalvanize existing steel for return to service or use on new project.Many projects can benefit from the expansion or adaptation of an existing steel structure through cutting, bolting, and welding. For example, when an existing steel building structure is desired for a new purpose, the structural framing may not immediately meet new design criteria without alteration (read More than Recycled Content: The Sustainable Characteristics of Structural Steel by AISC). The good news is the existing structural framing of a building can be easily expanded or modified to handle new load requirements instead of fully demolishing to build anew. This is the type of flexibility that allows a steel building frame originally designed to house a fire station to be redesigned for the needs of a multi-level restaurant. On the other hand, when steel has exceeded its design life on a project, there are also opportunities to reuse it for the construction of scaffolding, pipe racks, shoring, shelving, or non-structural but interesting visual components (read More than Recycled Content: The Sustainable Characteristics of Structural Steel by AISC).