The Metal Construction Association (MCA) has released new research findings showing certain metal roof systems can last at least 60 years, meaning they do not require replacement during a commercial building’s service life.

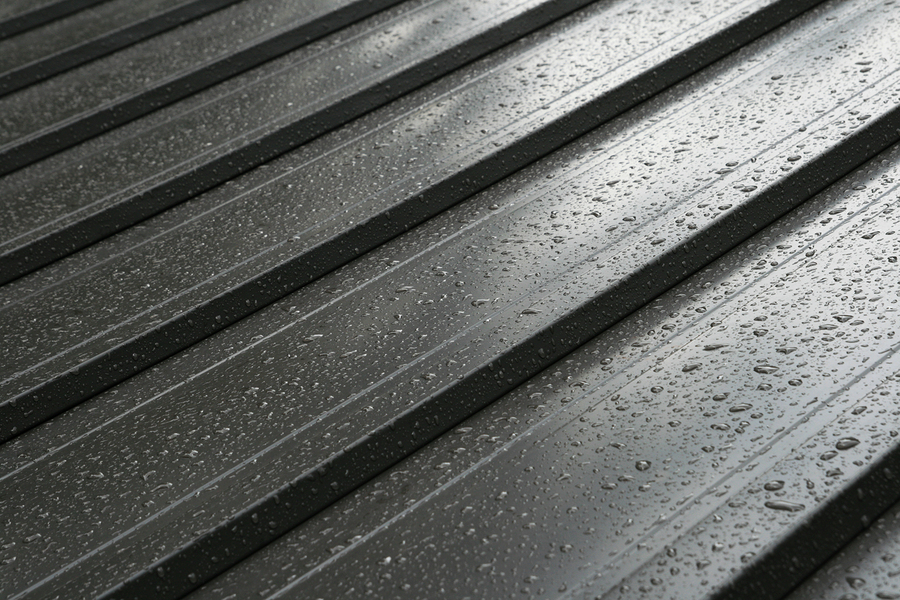

The study, sponsored by MCA and Zinc Aluminum Coaters (ZAC) Association, was conducted with oversight of three independent consulting firms that analyzed low-slope, unpainted aluminum-zinc (Al-Zn)-coated steel standing seam roofing in a wide range of environments across the United States. Common on low-rise commercial buildings (e.g. warehouses, schools, distribution centers, and shopping malls), this type of roof material is known by many trade names, including Galvalume and Zincalume.

The study incorporates the results of multiple field inspections and independent laboratory analyses of metallic panel corrosion of the roof panels. It includes assessment of all integral ancillary components, including sealants, impacting the roof’s service life.

The research team selected 14 building sites in five climate regions of various U.S. geographies, exhibiting a spectrum of climates related to heat and humidity including Hot-Dry, Hot-Humid, Cold-Dry, Cold-Humid, and Moderate-Arid. The precipitation acidity also varies considerably from one site to the next over this broad geography.

The research study concluded the expected service life of an unpainted 55 percent Al-Zn coated steel standing seam roof can be expected to be in excess of 60 years—a value equaling the assumed building service life as described in the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED) v4 rating program.

In the study, the steel panel roofs experienced corrosion rates that conservatively project service lives well beyond the service life of most buildings. The range depends on the climate and the local precipitation pH.

The study also confirmed these types of metal roofs resist corrosion even in ‘weak’ spots, such as sheared edges and panel profile bends. Inspections showed an absence of significant red rust after up to 35 years—this indicates exceptional corrosion resistance in areas susceptible to exhibiting the first signs of corrosion.

The study acknowledges all roof systems require a regular maintenance program (at least annually) to clean off debris and to inspect the roof’s condition to achieve the kind of service lives shown in this study. While low-slope steel standing seam assemblies were projected to last up to 60 years, ancillary components (e.g. fasteners) may need replacement during the roof life, but this represents significantly less than a fifth of a total replacement cost.

“This study… provides third-party, scientific data that backs up the long held stance that 55 percent Al-Zn-coated steel standing seam roofing systems are very durable, economic, and can be better for the environment,” said Scott Kriner, MCA’s technical director. Most non-metal roofing systems require one or more full replacements within a typical building’s 60-year service life, which is costly and can add to the solid waste stream in landfills.

“We are planning to conduct more studies on different types of metal roofing, and in some cases we expect similar or even better results in terms of roof service life,” he continued. “We think these studies will help motivate building owners and architects to specify metal roofing more often.”

The report was peer-reviewed by Morrison Hershfield laboratory in Canada.