Repair recommendations

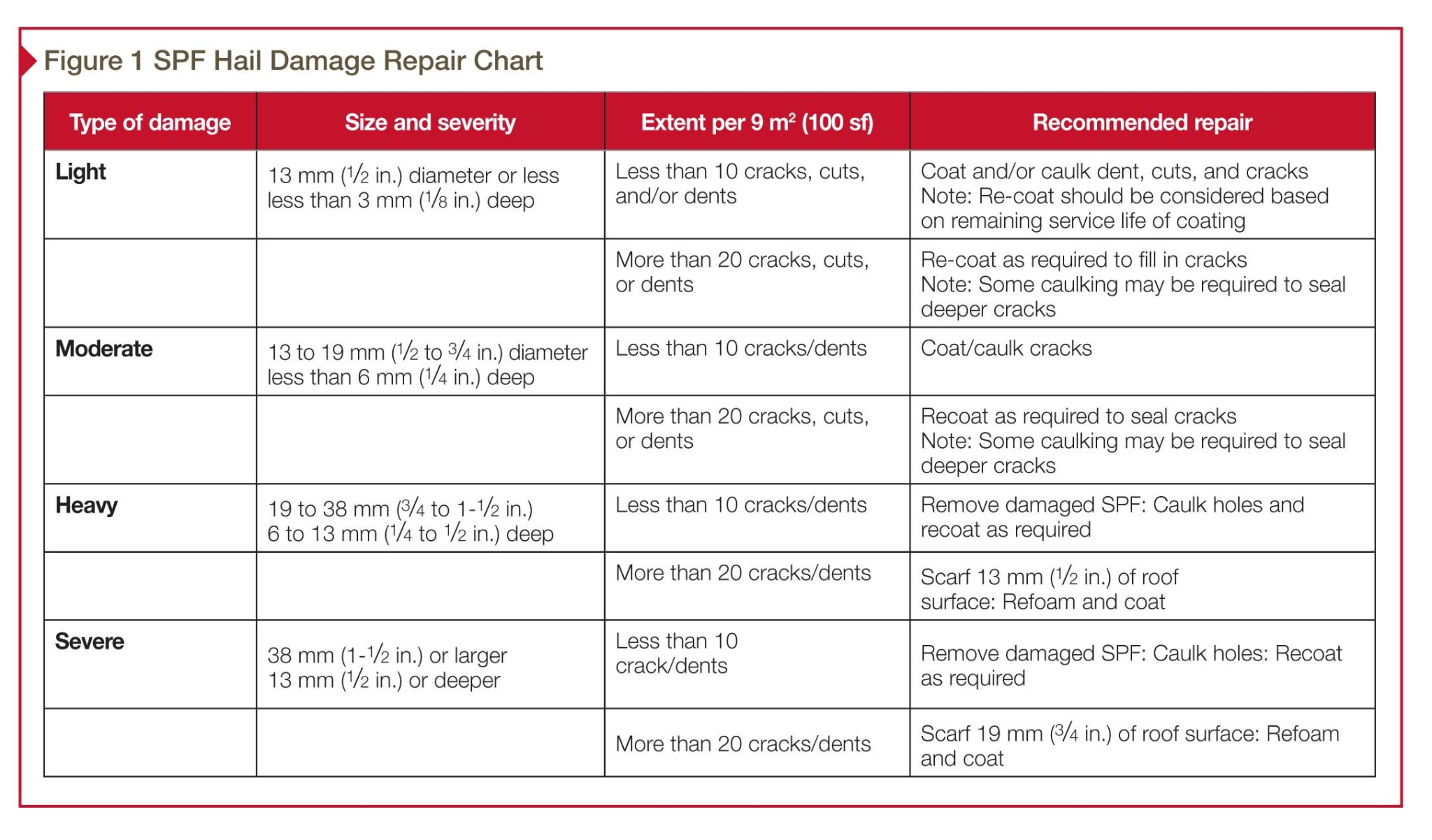

After obtaining information from the roof inspection, recommendations can be developed specific to the damage sustained. As discussed, repairs will vary depending on the severity and the frequency of the damage.

Figure 1, obtained from SPFA’s technical document AY 139, can help classify the mechanical damage and provide repair recommendations. Other factors affecting repair recommendations include age and condition of SPF and coating, service life expected of the roof system, cost of repair, and amount covered by insurance.

Climactic factors

The recommendations listed in Figure 1 are not specific to regions or varying climates. While the recommendations remain consistent in varying climates, consequences of untreated wind and hail damage to SPF roofs vary in different climates.

Hot arid climates

Assemblies in Phoenix or Las Vegas are more forgiving regarding light to moderate hail damage. However, cracks in the coating can allow UV degradation over time. This degradation may take months to occur, but typically does not affect the roof’s water-resistant characteristics since the low humidity and exceptional drying characteristics of the climate do not allow the SPF to saturate over time.

The main concern of light to moderate hail damage in this climate is to maintain the coating’s capacity for re-coat/renewal. Eventually, UV degradation of the SPF under the coating will affect the adhesion of the coating to the foam. It is recommended the damaged areas be removed and caulked or refoamed. It should be noted there are cases of lightly hail-damaged roofs in these areas being successfully recoated years later without any specific hail damage repairs occurring. Still, it is prudent to make hail damage repairs as soon as practically possible.

Hot humid climates

The climates found in locations such as South Texas and Florida have more complex factors affecting hail-damaged SPF roofs. High temperatures tend to dry out the moisture that has seeped into the cracks and crushed foam cells very quickly. On the other hand, the high humidity creates a higher potential for SPF saturation particularly during cooler times of the year. Lower-perm-rated coatings/coverings also increase the potential for moisture saturation of the hail-damaged roofs because they do not allow drying to occur as efficiently as higher perm-rated products. As in the hot arid climates, UV degradation that can affect coating adhesion typically occurs within a few months.

Cool climates

In cooler temperatures, the greater concern of hail-damaged roofs is moisture saturating into the SPF. There may be long periods where drying conditions do not occur. In many areas snow may stay on the roof for extended periods increasing the possibility of moisture saturation. It is important to repair crushed foam and coating cracks as soon as possible to prevent moisture saturation of the damaged areas.

Conclusion

Sprayed polyurethane foam roofing systems have unique characteristics that allow the repair rather than the replacement of the system after hail and wind damage. These damage repairs to SPF roofing systems vary according to size, severity, and the length of time after the initial defacing. It is important to inspect and evaluate the damage in order to make the correct repair recommendations. However, with the correct repair, SPF roofing systems can perform for many years after a significant wind or hailstorm.

Mason Knowles is president of Mason Knowles Consulting LLC, specializing in providing educational/training, troubleshooting problem applications, technical services and articles, and presentations specific for the sprayed polyurethane foam (SPF) industry. He has 42 years of experience in the sprayfoam industry as a contractor, manufacturer, and trade association executive. Knowles chairs the ASTM Subcommittee on Sprayfoam Roofing and the ASTM Task Group responsible for ASTM C 1029, Spray-applied Polyurethane Foam Specification. He is a Sprayed Polyurethane Foam Association (SPFA)-accredited building and roofing inspector and an instructor for SPFA courses for applicators and inspectors. Knowles is a member of the Roofing Industry Committee on Weather Issues’ (RICOWI’s) Hurricane and Hail Investigation Teams. He can be contacted at masonknowles@aol.com.

Great tips on SPF! After reading the first page, I was questioning whether this would be a good material to use. Then you shared the tips on ways to increase the resistance and I changed my mind quick. Thanks for sharing the information on what to look for during an inspection. Really helpful overall, thanks for sharing.

You shared some great tips here. I didn’t think I was going to learn as much as I did. Thanks so much for sharing!

There’s certainly a great deal to know about this topic. I like all the points you made.

This is a great article, and I appreciate you taking the time to write it. I have been in the roofing business for a long time, and have helped many customers with their roofing repairs, roof replacements, and new roofs.

The comparison between SPF roofing systems and other roofing materials, particularly in terms of hail resistance, provides readers with a comprehensive understanding of the advantages offered by SPF in mitigating damage and minimizing the need for extensive repairs or replacements.

Good to read this blog. In my experience, the best product to repair, maintain, and protect the roof is DIY EPDM liquid butyl rubber It is the most beneficial, cost-effective, durable sealant as its thick fluid effectively saturates little openings and miner defects, making a strong and stylishly satisfying look once wholly relieved. It can withstand ponding water 365 days a year and is also resistant to harsh weather conditions like heavy rainfall and hail storms. It’s the only liquid butyl rubber in the world that is solvent-based, having unique features that fix leaks the first time and flaking or future peeling. After the product dried, it looked like someone had put on a brand-new rubber membrane.