Testing Archaic Floor Systems

One of the chief concerns of anyone encountering an alternative concrete floor will always be: “Is it safe?” To best answer this question, one needs to look at the testing carried out at the time these floors were introduced, an informative look back at the history of building codes in the United States.

The most influential battery of tests was carried out by the New York City Bureau of Buildings in 1913, working with Columbia University. Fourteen different types of flooring systems were tested against each other: in the same conditions, using the same methods, and under the supervision of impartial observers. The test involved both traditional brick and terra cotta flooring against novel systems. At the time, there were no standardized tests for material assemblies. These would be the first and would form the basis for testing regimes to follow.

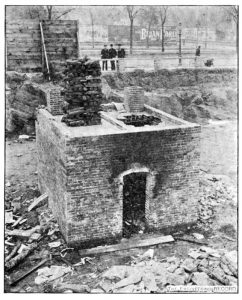

and the tile arch after rupture.

The test protocol was designed to judge fire resistance and was as direct as it was thorough. First, a sample of the floor system was built across four brick walls. The floor was loaded to 732.3 kg/m2 (150 psf) and, with that load in place, the assembly was subjected to increasing temperatures over a period of five hours, with more than three hours spent at more than 1093.3 C (2000 F). After this, the underside of the floor was hosed down with cool water to simulate the action of extinguishing a fire, and additional load was placed on the floor to bring it up to a total loading of 2929.4 kg/m2 (600 psf). The floors were monitored during testing, and measurements of deflection made at the final stage. The results of these tests proved these new systems superior to established brick and terra cotta floors and spurred their acceptance.

Problems and solutions

It is important for an owner or building professional to know about the presence of an alternative concrete system, preferably prior to any construction work or even design. While cutting into a slab is the surest way to verify the presence of an alternative concrete system, it is probably the least convenient or desirable. Severing the wires in these systems can seriously compromise their structural capacity.

Fortunately, there are some markers to look for suggesting the presence of an alternative concrete system. Building age is perhaps the key initial indicator; any building constructed between 1880 and 1920 has a good chance of having one of these systems in place, though examples can be found as late as 1950. When looking at the slab itself, the presence of unusual aggregate materials such as sawdust, wood chips, or cinders suggests archaic concrete construction. Damaged areas of the slab may expose reinforcing wires or mesh atypical for modern reinforced concrete, particularly on the underside of the slab where the curvature of the catenary may be visible. Less definitive but easier to observe is slab thickness: an unusually thick slab can be evidence for an alternative system.

These systems can present several problems. Relatively thin layers of concrete, like those used in cinder fill decks, can crack easily, and even without cracks the relatively porous concrete mixes used often admit water. Once inside, water can traverse cavities present in the design and saturate areas of loose fill, which then may remain wet for years, conducting water throughout the slab.

When water meets metal reinforcing materials, corrosion can occur quickly and weaken the slab. Due to their thin gauge, wire- and wire-mesh-based systems are especially susceptible to corrosion damage, which can quickly impact their strength. To make matters worse, chemicals present in cinder fill or aggregate can produce corrosive compounds, such as sulfuric acid, when mixed with water, accelerating deterioration. It is not uncommon to find wires in compromised slabs completely disintegrated, leaving only rust. Even in the absence of corrosive failure, cracking can cause the embedding concrete to lose enough integrity that individual wires are subject to ductile failure, as loads are not effectively distributed.

One question that can arise when encountering a slab with widespread failure of tensile wire is: how was it able to continue standing? The answers are varied. In many cases, loads are transferred to intact areas of the slab. The large number of tension members (wires) present means even a failure of numerous wires, provided they are not all localized, need not cause collapse. In many cases, even if a wire has failed at a given point, friction between the wire and the surrounding matrix allows it still to provide some structural function along the rest of its length. Perhaps most crucial to the survival of these floors is they were designed very conservatively with respect to loads, even by the standards of today, so the loss of some capacity does not necessarily leave them deficient.

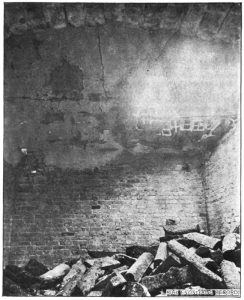

by corrosion.

Regarding structural capacity, it is also important to know how these floor systems are regarded by modern building codes. While not prohibited, these systems stand outside of modern code requirements. Perhaps the best passage referencing these systems is the International Building Code (IBC) 1604.4: “Any system or method of construction to be used shall be based on a rational analysis in accordance with well-established principles of mechanics.” While archaic, these systems are still based in sound empirical design and were subjected to testing equivalent to our standards today.

If code analysis needs to be performed, there are methods available to engineers. Any systems based on catenary action can use well-established statics along with spot measurements to determine wire size and spacing to calculate loading capacity. Simplified formulas for this analysis remain part of the building code in New York City today.

Still, there are limitations to the accuracy of these assessments. Damage to the floors can reduce load capacity or fire resistance. Seismic analysis and testing were not part of the original test protocols for these floor systems and may not be possible to evaluate due to the lack of data for some floor types.