Rethinking Cool Roofing: Evaluating effectiveness of white roofs in northern climates

by Molly Doyle | November 30, 2013 11:38 am

[1]

[1]by Craig A. Tyler, AIA, CSI, CDT, LEED AP

The use of white, reflective roofing materials throughout the United States has grown in popularity in recent years, but are these assemblies really ideal for all locations?

These types of roofs are increasingly specified, spurred by voluntary green building rating programs such as the U.S. Green Building Council’s (USGBC’s) Leadership in Energy and Environmental Design (LEED), along with codified systems such as the American National Standards Institute/Cool Roof Rating Council (ANSI/CRRC) 1-2010 Standard used in California’s Title 24. Many of these initiatives and codes rely heavily on research completed at the academic level with computer models and the results of tests performed to determine a material’s solar reflectance and thermal emission.

The result of the models and tests have shown using a reflective material yields net energy savings between the warm summer months and colder winter months in many areas of the country. However, under initiatives such as LEED, the building’s geographic location is given the same weight or value to the cool roofing, whether it is in Miami or Minneapolis—despite the fact these two locations have very different climates.

Research on the value and benefits of cool roofing is continuing within the industry, which is indicative cool, reflective materials still may not be the panacea of energy savings some are currently marketing. With this in mind, it is increasingly important for architects, specifiers, engineers, and design professionals to rethink use of cool roofing in every climate, especially northern regions.

[2]

[2]Energy costs

When properly designed and installed, reflective roofing materials can reduce building cooling costs during warm summers by ‘bouncing’ ultraviolet (UV) radiation away from the roof. This keeps the roof cooler, which allows the insulation to more efficiently maintain the building’s interior conditions. During winter months, the same materials reflect the UV radiation and keep the roof cooler. As a result, the roof insulation is not as efficient at keeping the building warm.

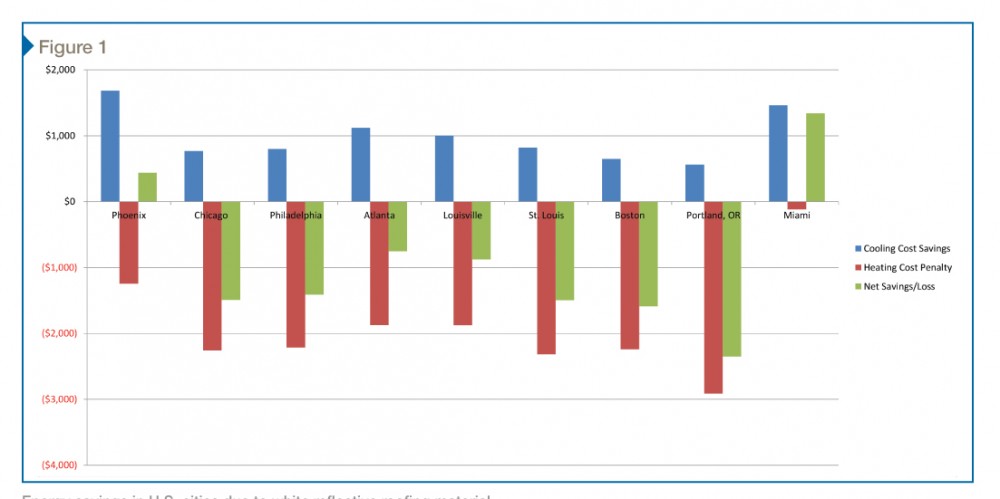

When calculating energy savings, the winter heating penalty is subtracted from the summer cooling benefit, which hopefully results in a positive net savings number. Using the Department of Energy (DOE) and Oak Ridge National Laboratory (ORNL) Roof Savings Calculator,1[3] major cities in various American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) Climate Zones (outlined in ASHRAE 90.1-2010, Energy Standard for Buildings Except Low-rise Residential Buildings) were selected for a cost comparison of using white reflective roof material for a one-story, 4645-m2 (50,000-sf) office building, R-20 insulation above deck, and low-slope roof construction.

The net energy savings shown in Figure 1 are positive for Phoenix and Miami, with the remaining cities showing a net loss. The use of darker-colored roofs shows a net energy savings in Chicago, Philadelphia, Atlanta, Louisville, St. Louis, Boston, and Portland. The table illustrates the use of white roofs to be energy-efficient in warmer southern climates, but not energy-efficient in colder northern climates.

Global warming

A recent study by researchers at Stanford University concluded white reflective roofs contribute to localized cooling in urban areas, but result in a net increase of global temperatures.2[4] This may be attributed to many factors (as stated in the study), but one area of concern could be attributed to the presence of brown and black carbon soot particles.

These particles absorb not only incoming solar radiation from the sun, but also the reflected heat and radiation produced by white roofs. The Stanford study argues while soot has a short lifetime, the air it heats can travel long distances—this suggests an additional method by which local changes due to white roofs can propagate to the large scale.3[5]

Condensation issues

In many cases, a white reflective roof is used in place of darker-colored material without consideration of differences. Every building project should be designed for the specific occupancy, geographic location, and desired performance characteristics.

Condensation is one of the most potentially destructive unintended consequences of cool roofing. It occurs when warm, humid air (generated through building occupancy and/or during construction) is present inside buildings. When the outside temperature falls, warm air inside the building rises toward the roof. In the absence of an air/vapor barrier, the warm, moist air rises and begins to form condensation when contacting any surface with a temperature below the dewpoint. This includes roof decks, roof insulation, and the underside of roofing materials.

[6]

[6]If warm, humid air infiltrates the roofing system, condensed moisture turns to frost and ice in below-freezing temperatures. The higher the humidity level inside the building, and the greater the temperature difference between the building’s inside and outside, the more condensation results.

In extreme cases (and especially with the use of a single layer of insulation), ice buildup caused by condensation can be noticed by a ‘cracking’ sound when walking on the membrane. Also, heavy ice formation along insulation joints can generate expansion forces that push laterally, causing insulation joints to widen. Condensation within the roof insulation may cause permanent damage, reduction of R-value, and loss of wind uplift resistance.

As the outside temperature rises and the roofing system assembly warms up, frozen moisture begins to thaw. This can result in drips inside the building. These drips are not associated with rainfall or snow accumulation on the roof—in fact, they are more likely to occur on sunny days when temperatures warm to above freezing.

The intensity of the drips is directly related to the amount of moisture intruding into and condensed within the roofing system assembly. The concentration of drips, however, is more likely to be seen around the perimeter and at deck end-laps.

HVAC performance

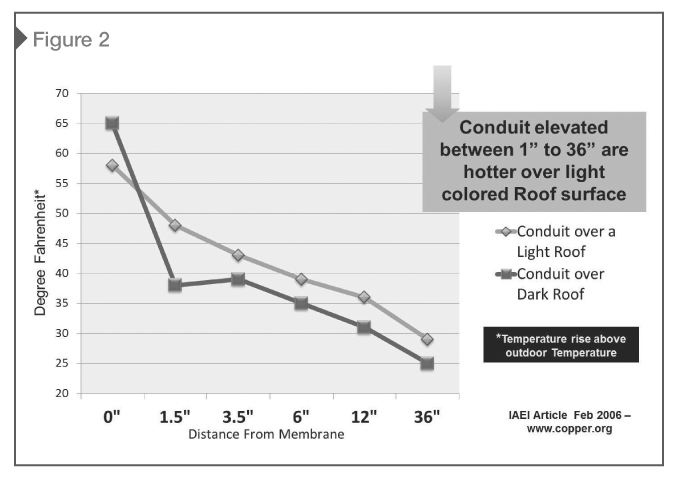

Several studies in recent years have validated the rooftop surface temperatures of white and darker roof materials, resulting in higher surface temperatures for dark roofs. This has been interpreted to translate to cooler rooftop temperatures for HVAC equipment and solar array efficiencies.4[7] However, a study performed by the Copper Development Association (CDA) in 2005 shows the contrary (Figure 2).5[8]

This study evaluated the impact of reflected heat on conductors and wiring used to control the operation of rooftop HVAC equipment. Heat sensors were mounted inside electrical conduits and placed at various elevations above black and white roof membranes, beginning at ‘ground’ and ending at 914 mm (36 in.). The change in ambient temperature inside the conduit was measured and recorded. The data led to the conclusion the air temperature became hotter inside the conduits mounted above white membranes than those above black ones. This correlates to hotter above-roof temperatures for HVAC equipment.

Winter safety

Darker-color roof materials absorb more UV radiation and have higher surface temperatures than their ‘cooler’ counterparts, year round. While this may be a perceived deficit during the summer, it is certainly a benefit in the winter. Not only does the dark roof surface aid in energy savings for the building, but it also helps melt snow and prevent ice buildup in colder temperatures.

Snow buildup on roofs is a major concern for every architect and engineer. Designing for the expected worst-case scenario is common practice, as well as assuming a certain amount of snow accumulation on rooftops. However, darker-colored roofs help alleviate this accumulation and formation of ice through the transfer of heat due to UV absorption.

Reflective surfaces can help create ice dams, as their surface temperatures are generally only a few degrees above ambient temperature. Caution should be used when placing conduits and pipes below the snow/slush line, since accumulated snow or ice can cause these pipes and conduits to act as snow guards and, if loosely laid on the roof, can move these lines.

Ice buildup on white reflective membranes can be hard to see for maintenance staff and roofers making repairs or servicing equipment. Caution should be used when inspecting these roofs throughout the winter and fall.

[9]

[9]Long-term performance

White roof materials reflect UV radiation and absorb a smaller amount of heat than do darker membranes. However, their long-term weathering can be shorter than their darker counterparts.

Among all artificial UV sources, xenon lights provide the best simulation of natural sunlight. With an appropriate filter combination, their irradiance spectrum can be adapted to closely match natural sunlight over a broad range of wavelengths.

The xenon arc weathering chambers have automatic control of light intensity, temperature, and humidity. Specific programs allow the samples to be sprayed with water or exposed to alternating cycles of dark and light periods.

The radiation dose is measured in kilojoules per square meter (kJ/m2) at 340 nm machine UV wavelength. The irradiance power of the xenon arc lamp is measured in watts per square meter (W/m2). The test specimen is a 70 x 140-mm (2 ¾ x 5 1/2-in.) membrane, unbacked, weathering side-facing arc lamp. The criteria for successfully passing the test is a minimum number of kJ/m2 of radiation based on the material set by the specific standard and that no visible cracks or crazing is evident when viewed under 10x magnification while wrapped around a 76-mm (3-in.) diameter mandrel.

[10]

[10]Polyvinyl chloride (PVC) can expect to receive 12,600 kJ/m2 of radiation. For ethylene propylene diene monomer (EPDM) assemblies, it can be 41,580 kJ/m2 for black membrane and 25,200 kJ/m2 for white. Meanwhile, thermoplastic polyolefin (TPO) range based on thickness (i.e. 1.14 to 2.03 mm [45 to 80 mils]) from 17,640 to 27,720 kJ/m2 of radiation.

The respective ASTM International test standards are:

- ASTM D4434, Standard Specification for Polyvinyl Chloride Sheet Roofing;

- ASTM D4637, Standard Specification for EPDM Sheet Used in Single-ply Roof Membrane; and

- ASTM D6878, Standard Specification for Thermoplastic Polyolefin Based Sheet Roofing.

Conclusion

When specifying roofing material color for a northern climate, it is important to be aware color is only one component of a roof system. The major contributor to energy savings in a roof assembly, rather, is the level of insulation used.

A roofing system should be determined during the design process based on geographic location, occupancy, service life, and level of insulation. Cool, reflective roof materials are better-suited for southern climates, while darker-colored roof materials perform well in northern climates. Combining the geographically appropriate roof color with the optimal R-value of insulation should result in an energy-efficient, sustainable roof.

Notes

1 For more on ORNL’s Roof Savings Calculator visit www.roofcalc.com[11]. (back to top[12])

2 See Mark Z. Jacobsen and John E. Ten Hoeve’s 2011 paper, “Effects of Urban Surfaces and White Roofs on Global and Regional Climate,” published by Stanford University’s Department of Civil and Environmental Engineering. (back to top[13])

3 See note 2. (back to top[14])

4 See S.R. Gaffin et al’s 2012 article, “Bright is the new Black: Multi-year Performance of High-albedo Roofs in an Urban Climate,” published in Environmental Research Letters (7). (back to top[15])

5 See Travis C. Lindsey’s article, “Effect of Rooftop Exposure on Ambient Temperatures Inside Conduits,” published in the January/February 2006 issue of International Association of Electrical Contractors’ IAEI News. (back to top[16])

Craig A. Tyler, M.Arch., AIA, CSI, CDT, LEED AP, is an architect and specification developer for Carlisle Construction Materials in Carlisle, Pennsylvania. He has a master’s of architecture from Savannah College of Art and Design (SCAD) and is a licensed architect in six states. Tyler has 15 years of experience, and has worked on commercial projects ranging from offices to multi-family housing. He can be contacted at craig.tyler@syntec.carlisle.com[17].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/loblaws-cut-test-2-Sept-20.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_November2013_HR-45-colour.jpg

- 1: #note1

- 2: #note2

- 3: #note3

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/CS_November2013_HR-46.jpg

- 4: #note4

- 5: #note5

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/DSC01652.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/04/Loblaws_01.jpg

- www.roofcalc.com: http://www.roofcalc.com

- top: #note6

- top: #note7

- top: #note8

- top: #note9

- top: #note10

- craig.tyler@syntec.carlisle.com: mailto:%20craig.tyler@syntec.carlisle.com

Source URL: https://www.constructionspecifier.com/rethinking-cool-roofing-evaluating-effectiveness-of-white-roofs-in-northern-climates-2/