Revitalization through copper pipes

by Katie Daniel | April 3, 2017 10:37 am

[1]

[1]by Andrew G. Kireta Jr.

The country’s drinking-water infrastructure recently received a ‘D’ on the American Society of Civil Engineers’ (ASCE’s) Infrastructure Report Card[2]—a nearly failing grade due to the millions of pipes in need of replacement. Currently, thousands of communities across the United States are distributing drinking water through old lead service lines. As a result of the Flint Water Crisis that began in 2014, homeowners and municipalities around the country have awakened to the fact that maintaining water infrastructure is critical. The best way to improve aging infrastructure and to eliminate the risk of lead poisoning is to remove and replace all lead service lines.

A study by the American Water Works Association (AWWA) estimates there are about 6.1 million lead service lines in the ground across 11,200 community water systems, but the lack of real data could make this a conservative estimate. (To read the 2016 article, “National Survey of Lead Service Line Occurrence,” click here[3].) As local officials, building owners, and taxpayers develop replacement strategies, they are making decisions that will affect the future. The cost of rectifying a bad decision can multiply drastically when digging up streets and lawns, shutting off water service, and disrupting customers’ lives enters the equation.

Material options

Currently, there are two main replacement materials for lead service lines: copper and plastic. Many municipalities found the latter choice’s low up-front costs alluring during the 1980s and 1990s when trying to keep pace with the construction boom. They turned to various plastic piping systems for underground water service line installations, causing copper’s market share for this application to slip from 75 percent through the mid-1970s to 50 percent by 2000.

However, this trend began to change through the early 2000s as the building boom continued. Some utilities and municipalities experienced issues with leaks and loss of water in plastic service lines. By the end of the decade, copper once again accounted for 80 percent of all water service line installations in the United States.

[4]

[4]Although the cost of a copper pipe may be three times that of a plastic one, the material cost represents only about five percent of the cost of replacing an underground line, with most of the expense coming in the excavation process. Utility experience across North America shows copper delivers a 75- to 100-year lifetime of use, while plastics have shown a lifetime of approximately 25 years. (To read “Underground Water Service Lines, Material Usage Trends: 1965−2009,” by Irwin P. Sharp & Associates, click here.[5]) Over the course of 75 years, the plastic system would need to be installed and then replaced twice, and the copper system would only have to be installed once.

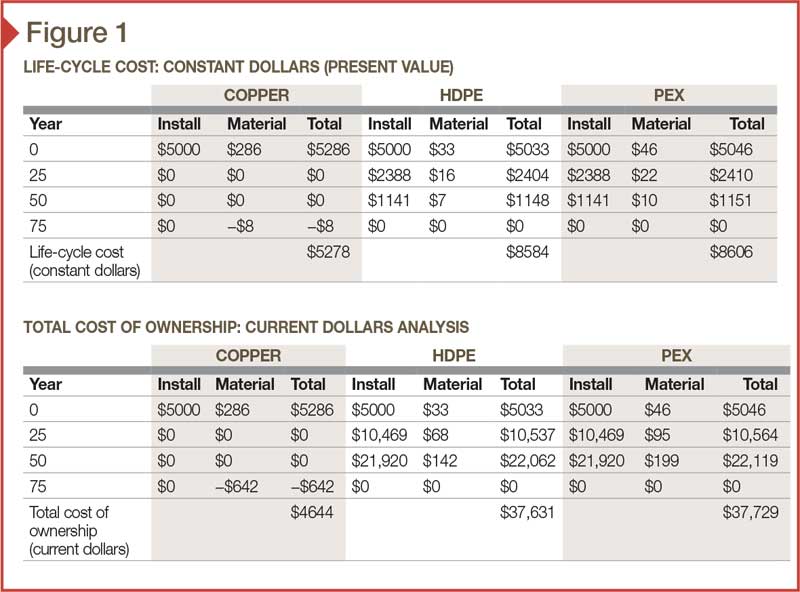

Figure 1 shows a life-cycle cost comparison of copper versus two plastic service line materials over the course of a planned 75-year service term. The analysis uses the following assumptions:

- installation cost is $5000 (this estimate is based on average service life cost);

- pipe size is 19 mm (3/4 in.);

- service line length is 19.8 m (65 ft);

- pipe material costs per 0.3 m (1 ft) of pipe are:

– copper (Type K) at $4.40;

– high-density polyethylene (HDPE) at $0.50; and

– cross-linked polyethylene (PEX) at $0.70.

The inflation rate was set at three percent.

[6]

[6]Proven safety and reliability

Copper has been used to deliver safe drinking water to civilizations for thousands of years. It was employed as a conduit material to distribute water at Abusir by the ancient Egyptians around 2150 BC, and it was widely used for water pipes and cisterns by the ancient Romans. Its extensive use has allowed for better understanding of its properties as well as its potential health and safety effects. Researchers know why leaching occurs and how it can be controlled.

While not common in most U.S. waters, copper can leach out of pipes. Some waters have low pH or very high alkalinity, in which cases copper leaching can exceed the federal mandated level. In the United States, only two to five percent of waters exhibit this natural trait, so it is not a major occurrence; more importantly, it can be predicted.

The U.S. Environmental Protection Agency (EPA) established the Lead and Copper Rule to regulate the amount of these metals in drinking water. Lead is regulated at 15 parts per billion (ppb) in water, which is 87 times more restrictive than the 1300 ppb allowable for copper. While lead is a quite serious neurotoxin that has severe adverse health effects associated with even very low intake concentrations, copper is necessary for human life and development. The copper level was set to protect against chronic effects (e.g. liver and kidney damage) occurring after prolonged exposure at high levels. This is particularly true for those with the genetic condition Wilson’s Disease, which affects an estimated one in 30,000 people in the country. These sensitive individuals cannot automatically regulate the levels of copper in the body, which can lead to a long-term buildup of copper and increase the likelihood of these chronic effects.

According to the EPA[7], no amount of lead ingestion as indicated by blood lead levels is safe for children, as it can cause developmental delays, irreversible cognitive and behavioral problems, anemia, seizures, coma, and other adverse health issues. However, regular ingestion of copper is essential for the development of bone, red blood cells, connective tissues, brain, heart, and other organs; it is also necessary in the absorption of other minerals and in the metabolizing of cholesterol and glucose.

Most knowledge on the health, safety, and reliability of piping materials comes from long-term use and service—a history plastics do not have. One of the reasons for this is when problems develop with the use of one type of polymer-based material, the industry switches to a different type of plastic. While this solves one problem, it also begins the learning curve for the next problem all over again—‘new’ often equals ‘unknown.’

However, recent studies[8] by AWAA and others indicate plastic materials (e.g. polyvinyl chloride [PVC], chlorinated polyvinyl chloride [CPVC], polyethylene [PE], polybutylene [PB], and acrylonitrile-butadiene-styrene [ABS]) can leach chemicals that affect taste and odor, but are difficult to identify. They also demonstrate certain products can be inconsistent between type of plastic and manufacturer and, most importantly, have little to no information on how these materials might affect human health.

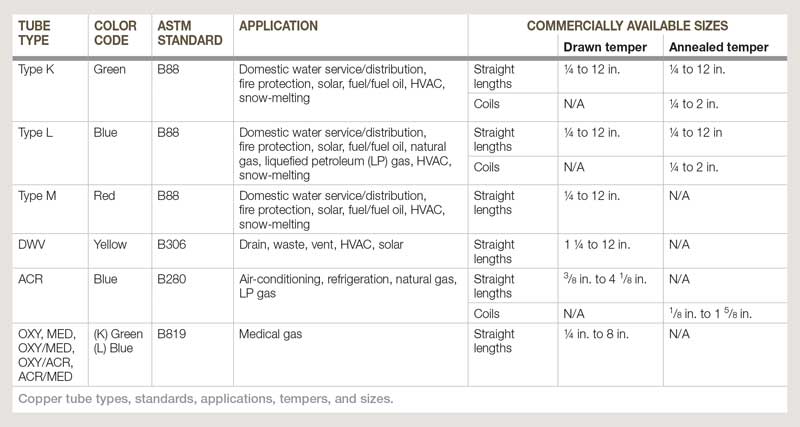

| COPPER TUBE 101 |

| Copper tube for plumbing applications is extruded from a solid copper billet or tube shell into a long, seamless tube made from 99.9 percent pure copper. Seamless copper tube is furnished according to several ASTM specifications in six standard types. Copper water tube (ASTM B88, Standard Specification for Seamless Copper Water Tube) is the most widely used; it includes Types K, L, and M tube (see table below). It is designated by nominal sizes, with the outside diameter being 3.2 mm (1/8 in.) larger than the nominal size. The only difference among the three types is their wall thickness, with Type K having the thickest wall and Type M the thinnest. These different tube sizes allow the system designer to optimize the design by selecting the type most closely matching the necessary pressure rating of the system. (For underground water services, Type K is recommended and most commonly used.)

Two other nominally sized copper tube types are available for specific applications. Copper drainage tube, Type DWV (ASTM B306, Standard Specification for Copper Drainage Tube) is available in hard temper for sanitary drainage, waste, and vent (DWV) applications. Medical gas tube (ASTM B819, Standard Specification for Seamless Copper Tube for Medical Gas Systems), also nominally sized, is available in hard temper, straight lengths only. It is furnished in Types K or L for different pressure applications. To maintain the utmost cleanliness of the medical gas distribution system until it is installed, the interior of this type of tube is specially cleaned and is supplied capped. Unlike the tube types previously mentioned, copper tube for air-conditioning and refrigeration field service (ACR) is not nominally sized. Like most of the components in the refrigeration and heat-transfer field, ACR tube (ASTM B280, Standard Specification for Seamless Copper Tube for Air-conditioning and Refrigeration Field Service) is designated by its actual outside diameter. As with medical gas tube, it is supplied cleaned and capped.

|

[10]

[10]On the other hand, copper service lines are completely impermeable, preventing outside chemicals that may be spilled on nearby streets or insecticides and fertilizers intentionally spread on yards from contaminating the water system. There has been no evidence copper can leach anything through the joints in the system. Flared, mechanical, and soldered/brazed joints create strong, durable, metal-to-metal seals.

The metal can also be exposed to ultraviolet (UV) rays and oxidizing disinfectants (e.g. chlorine, chloramines, and chlorine dioxide) without risk of cracking or failure. Meanwhile, plastic pipes have exhibited an above-average risk of premature failure due to oxidative degradation in underground potable water systems treated with an oxidizing disinfectant like chlorine.

Copper is also highly corrosion-resistant in most underground environments. The exception occurs in soils containing high concentrations of chlorides (from de-icing salts), sulfates, or ammonia that collect around the copper tube without draining. This is generally caused when the tube is installed in an unsealed sleeve or other conduit preventing drainage. Soils with high levels of sulfate or cinders can create sulfuric acid, which can attack copper and other metals.

Plastics can eliminate the risks of some types of corrosion, but they also introduce other risks such as oxidative degradation. Fortunately, copper corrosion can be prevented by proper system design, installation, and—in cases where water chemistry might be an issue—water treatment. Most causes of underground copper system failure stem from improper system installation, which is why the Copper Development Association (CDA) goes to great lengths to educate on proper installation and joining methods. (To learn more about copper piping and installation best practices, visit www.copper.org[11]. The Copper Tube Handbook can be accessed at www.copper.org/applications/plumbing/cth[12].)

Copper can also withstand high pressures and stresses without failures, while other materials crack, rupture, and leak, such as when used in underground applications where freeze-thaw and other natural occurrences cause the ground to settle and move.

Copper and plastic can both withstand freezing to a point, but both can also break if the line freezes because the ice plug in the line continues to grow in diameter, physically expanding the tube wall until it stretches beyond its elastic limit. Copper has a higher strength than plastic and can withstand a higher level of this stress before breaking. Plastics have shown to be less robust when exposed to freeze-thaw shifting—in other words, they crack.

| INSTALLATION BEST PRACTICES |

No matter what the material, poor installations can lead to poor performance. When installing copper underground service lines, here are some tips to keep in mind:

|

[13]

[13]Installation best practices

Officials in Flint, Michigan, have already begun replacing all the city’s lead pipes with copper. Mayor Karen Weaver launched FAST Start[14] in 2016 to get the lead out of Flint after a state-appointed emergency manager switched the city’s water source to the Flint River in 2014 without the necessary corrosion control chemicals being added. The corrosive water removed a protective coating on the inside of the pipes, causing lead to leach into the city’s drinking water.

While lead levels have been significantly reduced since the city switched back a year ago to water delivered from Lake Huron by the Great Lakes Water Authority, residents are still urged to drink only filtered water, and to replace their filters when needed. It is estimated as many as 29,100 homes have lead or galvanized steel service lines that need to be replaced—this project will cost an estimated $140 million.

Cities that have also begun to remove all lead pipes or laterals and replace them with copper include:

- Milwaukee, Wisconsin;

- Louisville, Kentucky;

- Lansing, Michigan;

- St. Paul, Minnesota; and

- Spokane, Washington.

In Wisconsin, the City of Madison initiated its own replacement programs using copper 15 years ago. The state capital replaced more than 8000 of its lead lines with copper from 2001 to 2011, after discovering lead levels over the federal limit. Instead of making minor changes and pushing a potential problem to future generations, city officials took action.

North of the border, Canadian cities have also been steadily working on replacing lead service lines with copper. In 2007, Montréal, Québec, announced the start of a multi-year program to replace approximately 75,000 lead service lines supplying water to residences of less than eight units built before 1970. Toronto, Ontario, is in the midst of a program to replace about 140,000 lead or galvanized steel services.

The common factor among these programs is a consistent, deliberate choice to replace lead with copper for long-term reliability of this hard-to-reach, hard-to-replace infrastructure—favoring life-cycle value over short-term cost. No matter how long it has been buried or in service, copper maintains its value, returning 80 to 90 percent or more of its original cost when it is reclaimed and sold for recycling. Its long life cycle, combined with its ease of recyclability back to the same metal purity (i.e. not downcycled to a lower purity or lesser use), makes it a sustainable piping material.

Conclusion

Given the expanding scope of the lead pipe problem in this country, CDA is working with individual water utilities and municipalities, providing credible technical information on the advantages of using copper tube for water service line replacements. CDA is also providing assistance in making proper design and installation considerations to help ensure a long and successful service life.

For example, CDA has been educating members of Congress on the urgent need to address the aging water infrastructure across the country. One important facet of this education is to ensure any legislation that funds or addresses lead service line replacements requires replacement of the full lead service line—not just the utility or building owner’s portion, leaving the remainder of the lead line in the system. According to a recent study in Environmental Engineering Science, creating a ‘hybrid’ system by replacing sections with alternate materials can exacerbate lead leaching, at least in the short term, into drinking-water tubes.

Besides its superior performance and reliability, copper is easy to work with. It can be joined using multiple leak-free methods, making it the preferred material among installers. In underground water service applications, flared or mechanical compression joints are most common. However, copper can also be brazed using standard fittings. With no-lead brass valves, fittings, and components, lead-free solders, and flameless, solderless joining systems, copper piping systems can represent the best option in reliable, long-lasting, lead-free service line installations, whether new construction or replacement.

| JOINING COPPER SYSTEMS |

| Copper plumbing tube can be joined using a variety of methods and fittings to match the specific application.

Pack-joint compression joints

|

Andrew G. Kireta Jr. is the vice president of the Copper Development Association (CDA) and is responsible for the use of copper and copper alloy systems and products in building construction applications, including plumbing, mechanical, and architectural systems. Since 1992, Kireta has been active in product development, specification, application, code, and standards acceptance, along with market promotion and education on use of copper in building construction. He can be contacted by e-mail at andrew.kiretajr@copperalliance.us[20].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_FAV-KellenCDA059.jpg

- Infrastructure Report Card: http://www.infrastructurereportcard.org/water-infrastructure

- here: http://www.awwa.org/publications/journal-awwa/abstract/articleid/57880483.aspx

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/CS_Apr_2017_HR-33.jpg

- here.: http://www.copper.org/applications/plumbing/water_service/resources/cda_water-service-trend-report-1965-2009.pdf

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_KellenCDA001.jpg

- EPA: http://www.epa.gov/ground-water-and-drinking-water/basic-information-about-lead-drinking-water#health

- recent studies: http://www.awwa.org/publications/journal-awwa/abstract/articleid/55379304/issueid/55120975.aspx?getfile=%5C%5Cpers75apppcr%5Cpersonify%5Cserverfiles%5Cdcdfiles%5C55379304%5Cjaw201604connell_pr.pdf

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/CS_Apr_2017_HR-34.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_FAV-KellenCDA093.jpg

- www.copper.org: http://www.copper.org

- www.copper.org/applications/plumbing/cth: http://www.copper.org/applications/plumbing/cth

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_FAV-KellenCDA125.jpg

- FAST Start: http://www.cityofflint.com/fast-start

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_7-16.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_9-1-e1490815353876.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_10-10.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_11-16.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/03/copper_12-1-e1490815498577.jpg

- andrew.kiretajr@copperalliance.us: mailto:andrew.kiretajr@copperalliance.us

Source URL: https://www.constructionspecifier.com/revitalization-through-copper-pipes/

[9]

[9] [15]Soldered and brazed

[15]Soldered and brazed [16]Flared joints

[16]Flared joints [17]Roll-grooved joints

[17]Roll-grooved joints [18]Press-connect joints

[18]Press-connect joints [19]Push-connect joints

[19]Push-connect joints